JXSC 250TPH Ilmenite ore processing project in Australia

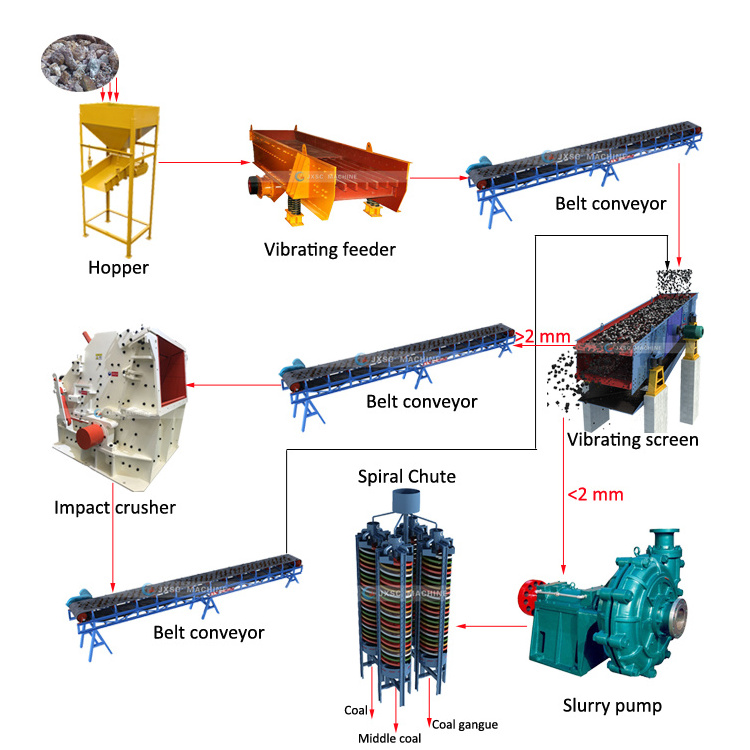

1) JXSC Chief Engineer Mr. Lee designed the flowchart and plants layout drawing based on customer's ilmenite ore conditions.

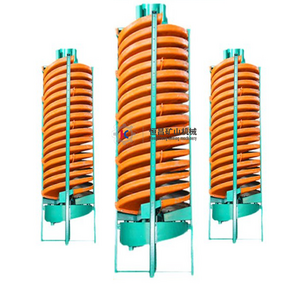

2) JXSC supplied full set ilmenite ore processing plant includes hopper, vibrating feeder, trommel scrubber washer, spiral chutes etc.

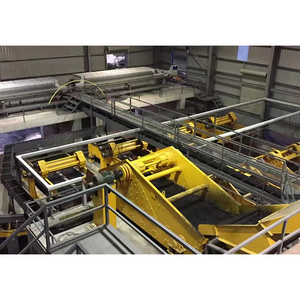

3) JXSC Chief Engineer Mr. Lee services at customer's ilmenite ore site to guide for installation, commissioning, start up and training.