- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

325

-

Weight:

-

500 KG

-

Place of Origin:

-

Henan,China

-

Voltage:

-

220-380

-

Power:

-

5.5kw

-

Key Machines:

-

metage

-

Product name:

-

screw feeder with hopper

-

Application:

-

Construction Project

-

Name:

-

screw conveyor

-

After-sales Service Provided:

-

VIDEO SUPPORT

-

Keywords:

-

Handling material

-

Type:

-

Electric

-

After Warranty Service:

-

Online service

-

Usage:

-

Wide Usage

-

Model:

-

Mobile

-

Color:

-

Customer Required

Quick Details

-

Machinery Capacity:

-

300

-

Brand Name:

-

Haolu

-

Year:

-

2023

-

Dimension(L*W*H):

-

325

-

Weight:

-

500 KG

-

Place of Origin:

-

Henan,China

-

Voltage:

-

220-380

-

Power:

-

5.5kw

-

Key Machines:

-

metage

-

Product name:

-

screw feeder with hopper

-

Application:

-

Construction Project

-

Name:

-

screw conveyor

-

After-sales Service Provided:

-

VIDEO SUPPORT

-

Keywords:

-

Handling material

-

Type:

-

Electric

-

After Warranty Service:

-

Online service

-

Usage:

-

Wide Usage

-

Model:

-

Mobile

-

Color:

-

Customer Required

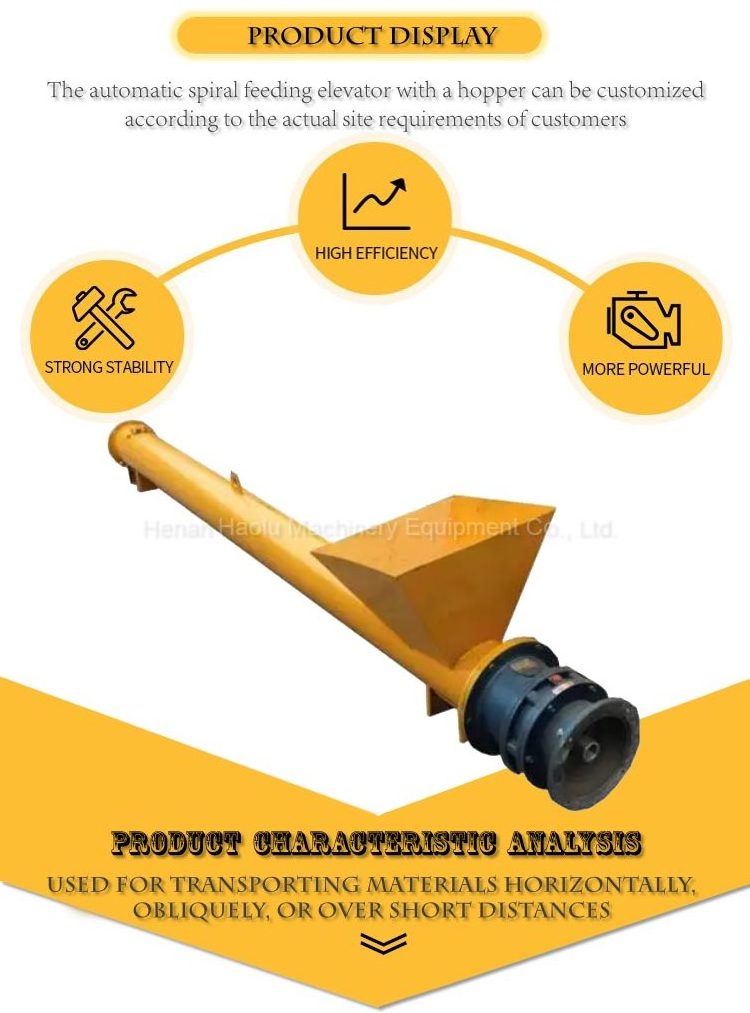

Introduction to screw conveyor products

Screw conveyor is divided into U screw conveyor and round tube screw conveyor. When the shell of the screw conveyor is installed horizontally, it is generally U-shaped groove, and when the tilt Angle is large or vertically fixed, it is generally circular tube type. The screw conveyor consists of a shaft and blades arranged along a spiral line on the shaft. Solid blade screw is used when conveying dry, small viscous powder and granular materials; Belt blade screw for conveying large viscous or block materials; The propeller blade screw is used to transport the material which is easy to bind. The screw can not only push the material but also play the role of breaking the knot. The conveying distance is generally within 70 meters, and the projected diameter of the spiral is below 1250 mm. Screw conveyor can be loaded and unloaded in many places, good sealing, and can transport materials with a temperature below 200℃.

Application of screw feeder

1.Suitable for building materials, chemical industry, electric power, metallurgy, coal, food and other industries,

2.It is suitable for horizontal or inclined transportation of powdery, granular and small block materials (such as coal, dust, residue, cement, grain, etc.).

When the stainless steel screw conveyor is working, the rotating spiral blade will push the material and transport it, so that the material does not rotate with the spiral elevator blade is the material's own weight and the friction resistance of the spiral elevator shell to the material. The spiral blade is welded on the rotating shaft of the spiral hoist, and the surface shape of the blade has solid surface type, belt surface type, blade surface type and other types according to the different conveying materials. The screw shaft of the screw elevator has a thrust bearing at the end of the direction of material movement. When the screw tube is long, the middle hanging bearing should be added.

Vertical screw conveyor and pipe screw conveyor belong to special screw conveyor. The shell is a round tube, and the centrifugal force generated after the screw drives the material to rotate at high speed pushes the material to the wall of the tube, and then is pushed upward by the blade, and there will be no stuck material phenomenon. Its lifting height is within 20 meters, generally 5 to 10 meters. LS type screw conveyor is widely used in various sectors of the national economy, such as building materials, metallurgy, chemical industry, electricity, coal, machinery, light industry, grain and food industry, suitable for conveying powdery, granular, small block materials, such as cement, coal powder, grain, fertilizer, ash, sand, coke and so on. It is not suitable to transport easily deteriorated, viscous, easy to caking materials,LS screw conveyor working environment temperature is usually -20 ~ 40℃, the temperature of conveying materials is generally -20 ~ 80℃, if there are special requirements, please contact our technical department for a separate design.

Product Paramenters

|

Screw feeder

|

|

|

|

|

|

|||||

|

Weighing

|

LS-200

|

LS-250

|

LS-315

|

LS-350

|

LS-400

|

|||||

|

Screw feeder

|

LS-200

|

LS-250

|

LS-300

|

LS-400

|

LS-500

|

|||||

|

Tilt angle

|

0-90°

|

|

|

|

|

|||||

|

Conveying speed

|

customizable

|

|

|

|

|

|||||

Product advantages

The use of variable diameter structure, increase the volume of the lifting bearing, avoid the contact between the lifting bearing and the material, extend the service life of the lifting bearing, reliable sealing: reliable lubrication seal without leakage, neither waste of material phenomenon, but also create a good working environment.

High efficiency conveying:

small diameter, high speed, large pitch helix design, to ensure that the product in the working process smooth, fast, uniform feeding.

Diversified connection:

the inlet and outlet can be connected by universal joint, cloth bag and flange, and can also be combined with butterfly valve and insert valve.

Innovative design:

Advanced and reasonable design, combined with advanced manufacturing technology and perfect quality assurance system, so that it has a small volume, large bearing torque, low noise, no oil leakage and other significant advantages.

Installation and commissioning

Before installation, the screw conveyor parts are counted, and the installation personnel fully understand the following installation requirements of the screw conveyor, and then the installation work can be carried out.

The screw conveyor should have stable support to prevent the sinking of the screw conveyor and additional deformation. To ensure that the screw conveyor has enough stability when working.

Install the drive device and coupling according to the order of the head section, middle section and tail section, and refer to the installation drawing of the equipment and the number of each screw section.

Gaskets can be added between the section and the section, between the top cover and the tank to ensure the sealing of the tank, and the length error of the tank can be adjusted.

The flange of the adjacent casing should be connected smoothly and tightly, and the dislocation deviation of the inner surface of the casing should not exceed 2mm.

Henan Haolu Machinery Equipment Co., Ltd.

has been focusing on construction machinery for more than 18 years. Our company has an

independent research and design team.

The production workshop is equipped with professional automatic production equipment. Main products are building materials elevator, gantry elevator, concrete mixer, cement tank, batching machine, screw conveyor, belt conveyor,

weighing and other construction machinery.

Extensive experience can provide professional customization and foundry processing services.

Q: What information should I provide when I ask about the product?

A

: The more specific the information, the better service we can provide.

1. Tell us the materials to be delivered.

2. Tell us which machines it needs to be attached to.

3. Tell us its height from the ground, tilt Angle and conveying length.

4. Tell conveying capacity.

Q: Are you trading company or manufacturer?

A:

We are factory. We can design and manufacturer products with our patent. Welcome to visit us to check it!

Q: What are the terms of payment in your formal trade?

A:

Normally we can work on T/T term ,L/C term and Alibaba Trade Assurance Order Online .

T/T:

30%T/T prepayment , 70% paid by T/T before delivery.

L/C:

100% irrevocable L/C at sight.

Q: What’s your after-sale service?

A:

12 months warranty for main parts since departure. On-site installation, debugging, workers training. Make sure that your workers operate properly and know daily maintenance well.

Q:What’s your delivery time?

A:

The goods will be delivered in 30-45 days after the 30% of the total amout is paid as deposit, and maybe a little longer if busy in the factory.

B:

Generally it is 7-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Hot Searches