- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Hdpe Double Wall Corrugated Pipe

-

Specification:

-

DN110-DN1200,SN4,SN8

-

Length:

-

5.8m;6m,12m or as requirement

-

Thickness:

-

9mm-66.2mm

-

Standard:

-

ISO4427, EN, DIN, AS, ASTM, GB/T19472.1-2004 )

-

Color:

-

Black,white, yellow, orange or according request

-

Connection:

-

Socket Fusion with rubber ring,or with heat shrinkable tape

-

Usage:

-

Sewerage, drainage system

-

Certification:

-

CE ISO

-

lifespan:

-

70 years underground

-

product Name:

-

Hdpe Double Wall Corrugated Pipe

-

Pressure:

-

SN4,SN8

-

Feature 1:

-

Green environmental protection

-

Application:

-

waterlogging; chemical and mine for fluid transportation

-

Feature 2:

-

Corrosion Resistance

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

hesu 36 inch hdpe corrugated pipe

-

Model Number:

-

Hdpe Double Wall Corrugated Pipe

-

Specification:

-

DN110-DN1200,SN4,SN8

-

Length:

-

5.8m;6m,12m or as requirement

-

Thickness:

-

9mm-66.2mm

-

Standard:

-

ISO4427, EN, DIN, AS, ASTM, GB/T19472.1-2004 )

-

Color:

-

Black,white, yellow, orange or according request

-

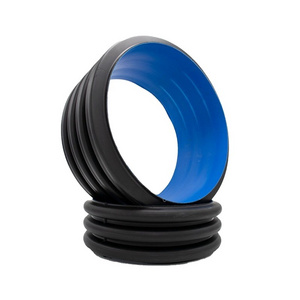

Connection:

-

Socket Fusion with rubber ring,or with heat shrinkable tape

-

Usage:

-

Sewerage, drainage system

-

Certification:

-

CE ISO

-

lifespan:

-

70 years underground

-

product Name:

-

Hdpe Double Wall Corrugated Pipe

-

Pressure:

-

SN4,SN8

-

Feature 1:

-

Green environmental protection

-

Application:

-

waterlogging; chemical and mine for fluid transportation

-

Feature 2:

-

Corrosion Resistance

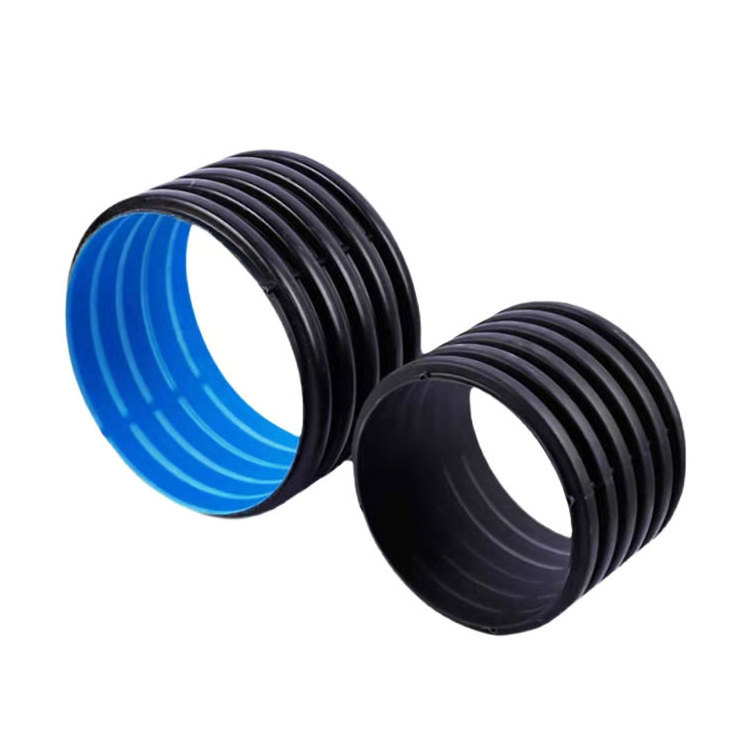

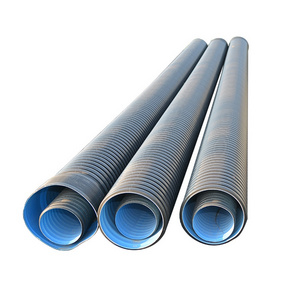

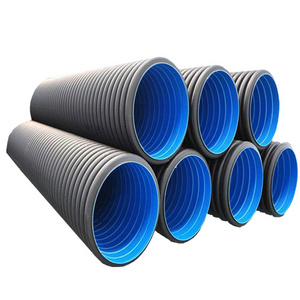

400mm sn8 double wall corrugated hdpe plastic culvert pipe

Welcome to HESU HOME

Professional HDPE pipe/ PVC pipe manufacture

we are sincerely recruit agents from all over the world.

Product Description

|

Product Name

|

HDPE Double-wall Corrugated Pipe

|

|

Color

|

Black

|

|

Specification

|

DN200-DN800mm

|

|

Ring stiffness

|

SN4 SN6 SN8

|

|

Length

|

6m / piece or according to your requirements

|

|

Main application

|

Drainage and sewage, irrigation, water conveyance, waterlogging drainage, fluid transportation,etc

|

|

Guarantee

|

70 years

|

Product Paramenters

|

Inner diameter

DN (mm) |

Minimum

Average Inner Diameter d (mm) |

Minimum

joints layer thickness e (mm) |

Minimum

inner layer thickness e 1 (mm) |

Jointing

length A(mm) |

EXW price

(USD/M)

|

|

|

|

|

|

|

|

|

SN4

|

SN8

|

|

|

200

|

195

|

1.5

|

1.1

|

54

|

3.762

|

4.918

|

|

|

300

|

294

|

2.0

|

1.7

|

64

|

6.443

|

8.73

|

|

|

400

|

392

|

2.5

|

2.3

|

74

|

11.066

|

14.508

|

|

|

500

|

490

|

3.0

|

3.0

|

85

|

14.164

|

21.639

|

|

|

600

|

588

|

3.5

|

3.5

|

96

|

27.541

|

30.492

|

|

|

700

|

687

|

4.0

|

4.0

|

107

|

43.796

|

51.338

|

|

|

800

|

785

|

4.5

|

4.5

|

118

|

48.492

|

55.377

|

|

Physical properties of double-wall plastic corrugated pipe GB/T19472.1-2004:

|

Item

|

|

Index

|

||

|

Ring stiffness(KN/㎡) |

SN2

|

≥2

|

||

|

|

SN4

|

≥4

|

||

|

|

(SN6.3)

|

≥6.3

|

||

|

|

SN8

|

≥8

|

||

|

|

(SN12.5)

|

≥12.5

|

||

|

|

SN16

|

≥16

|

||

|

Impact performance(TIR)/ %

|

|

≤10

|

||

|

Ring flexibility

|

|

The sample is smooth, no reverse bending, no cracking, no disengagement of the two walls

|

||

|

Oven test

|

|

No bubbles, no delamination, no cracking

|

||

|

Creep ratio

|

|

≤4

|

||

|

Note: The values in parentheses are non-preferred ring stiffness grades.

|

|

|

||

Details Images

Features:

1. Unique structure, high strength, compression and impact resistance.

2, the connection is convenient, the joint is well sealed, and there is no leakage.

3, light weight, quick construction and lower cost.

4. The buried service life is more than 50 years.

5. Polyethylene is a hydrocarbon polymer with non-polar molecules and resistant to acid and alkali corrosion.

6. The raw materials are green environmental protection materials, non-toxic, non-corrosive, non-scaling, and can be recycled and used.

7. The use temperature range is wide, the pipe will not break in the environment of -60℃, and the temperature of the conveying medium is 60℃.

8. The comprehensive project cost is basically the same as that of the concrete, and the operating cost is low.

9. No foundation is needed if the soil quality is good.

1. Unique structure, high strength, compression and impact resistance.

2, the connection is convenient, the joint is well sealed, and there is no leakage.

3, light weight, quick construction and lower cost.

4. The buried service life is more than 50 years.

5. Polyethylene is a hydrocarbon polymer with non-polar molecules and resistant to acid and alkali corrosion.

6. The raw materials are green environmental protection materials, non-toxic, non-corrosive, non-scaling, and can be recycled and used.

7. The use temperature range is wide, the pipe will not break in the environment of -60℃, and the temperature of the conveying medium is 60℃.

8. The comprehensive project cost is basically the same as that of the concrete, and the operating cost is low.

9. No foundation is needed if the soil quality is good.

Application Field

1. Drainage and ventilation pipes for mines and buildings;

2. Municipal engineering, underground drainage and sewage pipelines in residential quarters;

3. Irrigation and drainage of farmland water conservancy; drainage pipes for sewage treatment plants and garbage disposal sites;

4. Chemical ventilation pipes and chemical and mining fluid conveying pipes;

5. The overall processing of pipeline inspection wells; high-speed kilometers of pre-buried pipelines;

6, high-voltage cables, post and telecommunications cable protection sleeves, etc.

2. Municipal engineering, underground drainage and sewage pipelines in residential quarters;

3. Irrigation and drainage of farmland water conservancy; drainage pipes for sewage treatment plants and garbage disposal sites;

4. Chemical ventilation pipes and chemical and mining fluid conveying pipes;

5. The overall processing of pipeline inspection wells; high-speed kilometers of pre-buried pipelines;

6, high-voltage cables, post and telecommunications cable protection sleeves, etc.

Accessories:

Packing & Delivery

Hot Searches