- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Aceretech

-

Application:

-

plastic waste washing line, Plastic Recycling Machine

-

Production Capacity (kg/h):

-

100 - 1500 kg/h

-

Voltage:

-

Customzied

-

Dimension(L*W*H):

-

Customzied

-

Power (kW):

-

Customzied

-

Weight (T):

-

20

-

Name:

-

Plastic Washing Line

-

Raw material:

-

HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS

-

Advantage:

-

Famous Brand Motor

-

Business type:

-

Manufacturer

-

Sample/Service Manual/Supply type:

-

Available

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

1500

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Aceretech

-

Application:

-

plastic waste washing line, Plastic Recycling Machine

-

Production Capacity (kg/h):

-

100 - 1500 kg/h

-

Voltage:

-

Customzied

-

Dimension(L*W*H):

-

Customzied

-

Power (kW):

-

Customzied

-

Weight (T):

-

20

-

Name:

-

Plastic Washing Line

-

Raw material:

-

HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS

-

Advantage:

-

Famous Brand Motor

-

Business type:

-

Manufacturer

-

Sample/Service Manual/Supply type:

-

Available

360 VR Show Room

ACERETECH Recyclable Plastics Include

● LLDPE/LDPE/HDPE/PE/EPE film, crushed material, lithium battery film, foamed pearl cotton

● PP/OPP/BOPP/CPP film, woven bag,non-woven fabric (melt blown)

● PA66 fishing net, silk, factory trim, carpet

● PET/BOPET bottle flakes, film, silk, waste cloth, foam,optical film

● PTT wire

● EPS/XPS crushed material, cold briquetting foam, hot melt foam, insulation board

● HIPS/PC/ABS home appliance housing, electronic waste, factory plastic

● PVB crushed material, flakes

● PU

Suitable Products

Product Paramenters

|

Device parameters

|

|

|

|

|

||||

|

Size

|

Capacity

|

|

Motor Power

|

Equipment footprint

|

||||

|

AWS-PET10

|

1000kg/h

|

|

220KW

|

250m 2

|

||||

|

AWS-PET20

|

2000kg/h

|

|

260KW

|

350m 2

|

||||

|

AWS-PET30

|

3000kg/h

|

|

380KW

|

500m 2

|

||||

|

AWS-PET40

|

4000kg/h

|

|

500KW

|

700m 2

|

||||

|

Unit energy consumption

|

|

|

|

|

||||

|

Content

|

|

Average energy consumption per ton of bottle

|

|

|

||||

|

Electricity

|

|

70-90KW

|

|

|

||||

|

Water

|

|

1-1.5T

|

|

|

||||

|

Compressed air

|

|

0.5-1m3

|

|

|

||||

|

Steam (optional)

|

|

250-400KG

|

|

|

||||

|

Detergent (optional)

|

|

4-8KG

|

|

|

||||

|

Bottle quality reference

|

|

|

||

|

Description

|

AA(ppm)

|

A(ppm)

|

||

|

PVC content

|

≤25

|

≤100

|

||

|

PE/PP/colored bottle/metal/other

|

≤75

|

≤100

|

||

|

Total impurity

|

≤100

|

≤200

|

||

Product Detail

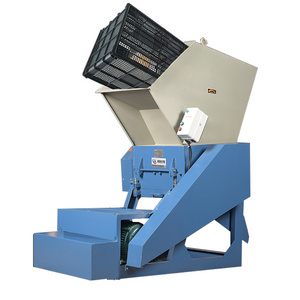

CHAIN PLATE CONVEYOR

The PET plastic bottle washing line is equipped with chain plate conveyor, which is wide and convenient for the transportation of plastic waste bottles

.

DE-BALER

De-baler is mainly used to break up compacted waste plastic bottles, so that they can be loosened and better entered into the next process.

BELT CONVEYOR

●

Conveying raw materials into next parts.

●

Controlled by inverter, belt speed is adjustable.

●

Function: bottles conveying

●

Width of belt: 1000mm

●

Basic material of belt: PVC

●

Motor power: 2.2KW

TROMMEL

●

Function: remove stone, dust, loosen caps and small metal

●

Basis material: Galvanized carbon steel

●

Frame: Carbon steel

●

Diameter of barrel : 1500mm

●

Length : 5000mm

●

Motor power: 5.5KW

●

The hole diameter:50mm

FERROUS REMOVER

●

Function: Equipped above the conveyor belt, used to remove iron, chromium, manganese and other ferrous

●

Power:3KW

LABEL REMOVER

●

Function: remove above 90% labels for both common and compressed bottle

●

No flakes waste and no water consumption

●

Motor power: 15KW

●

Suction fan power: 5.5KW

●

Rotary blade : 42pcs(teeth 378pcs)

●

Fixed blade : 45sets * 4 = 180pcs(teeth 1080pcs)

PRE-WASHER

●

Function: bottle washing, remove small size impurity, decrease the working pressure for down

stream. Tank body SS304

●

Diameter:1500mm

●

Length:6000mm

●

Motor power:7.5KW

●

Power of screw:2.2KW

●

Diameter : 250mm

SCREW LOADER

Equipped with multiple rolling screws, the material is screened by rolling, and the impurities can fall from the gap to the impurity receiving port below.

DISK SEPARATOR

Equipped with a disk separator, PET plastic bottles pass through the bouncing screen to remove loose impurities, labels, caps, etc.

BOTTLE SORTING MACHINE

The material sorting of the whole bottle can be sorted according to factors such as the color required by the customer, and the PET bottle of the same color category can be carried out to the next process.

MANUAL SORTING

The material is divided into two double stations through manual sorting for manual sorting.

CRUSHER

●

Divide large-size raw materials into relatively uniform small-size raw materials through crushing.

●

Crushing bottle to small flakes.

SCREW LOADER

●

Function: PET flakes conveying

●

Motor power: 4KW

●

Dia. of screw: 310mm

●

Part contact with raw materials: stainless steel

SEPARATION FLOATING TANK

●

Function: wash flakes and remove floating material as PP,PE and Caustic Soda

●

Motor power of screw loader: 5.5KW

●

Motor power of thumbwheel: 0.55KW

●

Quantity of thumbwheel: 3 sets

●

Dia. of screw:250mm

●

Part contact with raw materials: stainless steel<

Equipped with water tank and pump

LABEL SEPARATOR

Remove impurities such as residual PET bottle labels

.

HOT WASHER

●

Function: after hot washing, it’s easier to remove oil, glue

●

Motor power: 5.5KW

●

Volume of hot chamber≈4.07 m3

●

Outer layer: Carbon steel

●

Inner layer: stainless steel

●

Middle layer: rock wool for insulation

●

Caustic soda percentage:1-2%

●

Temperature of hot water:70-90 centigrade

●

Non-stop flakes feeding and loading out

.

HIGH SPEED FRICTION WASHER

●

Function: remove the glue and dirty

●

Motor power: 30KW

●

Motor power of water pump:1.5KW

●

Rotary speed of screw: 1200rpm

●

Part contact with raw materials: stainless steel

CENTRIFUGAL DRVER

●

Function: Drying and flakes moisture reach 2%

●

Motor power: 22KW

●

Motor of cover open:0.75KW

●

Rotary speed of screw: 2200rpm

●

Part contact with raw materials: stainless steel

.

PIPELINE DRVER

●

Function: hot air drying, moisture < 1%

●

Heating power: 48KW,if adopt steam heating, this

●

electric consumption will be saved

●

Power of blowing motor:5.5KW

●

Power of suction motor: 5.5KW

.

VIBRATION DRYER

Drying of washed PET bottle flakes through a vibrating sieve.

VIBRATION DRYER

●

With CE/CSA/TUV/SGS/ISO standard, all parameters can be set on the touch screen.

●

Electric control component: (Schneider), e.g. Circuit-breaker, AC contact, press button, pilot lamp.

●

For electrical controlling of the entire system.

●

Safety interlock principle.

●

All electrical units: LS, Schneider, ABB.

Hot Searches