- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

700 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Doing Machine

-

Voltage:

-

380V,50Hz,3P

-

Dimension(L*W*H):

-

2500*1350*2450mm

-

Power (kW):

-

4 kW

-

Model:

-

EYH series

-

Mixing barrel volume:

-

300-5000L

-

Capacity:

-

200-2500kg/batch

-

Motor power for rotary:

-

1.1-7.5 kw

-

Motor power for swing:

-

0.75-5kw

-

construction material:

-

SUS304/SUS316L

-

Applied material:

-

powders and granules

Quick Details

-

Barrel Volume (L):

-

1000 L

-

Max. Loading Volume (L):

-

500 L

-

Range of Spindle Speed(r.p.m):

-

3 - 12 r.p.m

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

700 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Doing Machine

-

Voltage:

-

380V,50Hz,3P

-

Dimension(L*W*H):

-

2500*1350*2450mm

-

Power (kW):

-

4 kW

-

Model:

-

EYH series

-

Mixing barrel volume:

-

300-5000L

-

Capacity:

-

200-2500kg/batch

-

Motor power for rotary:

-

1.1-7.5 kw

-

Motor power for swing:

-

0.75-5kw

-

construction material:

-

SUS304/SUS316L

-

Applied material:

-

powders and granules

Product Description

Main features

1. For mixing dry powders or small granules with good flowability

2. Particularly good at mixing materials with different bulk density and particle size range

3. Mixing vessel volume: 300-5000L;

4. GMP design

5. Vacuum conveyor can be equipped for automatic and dust-free feeding

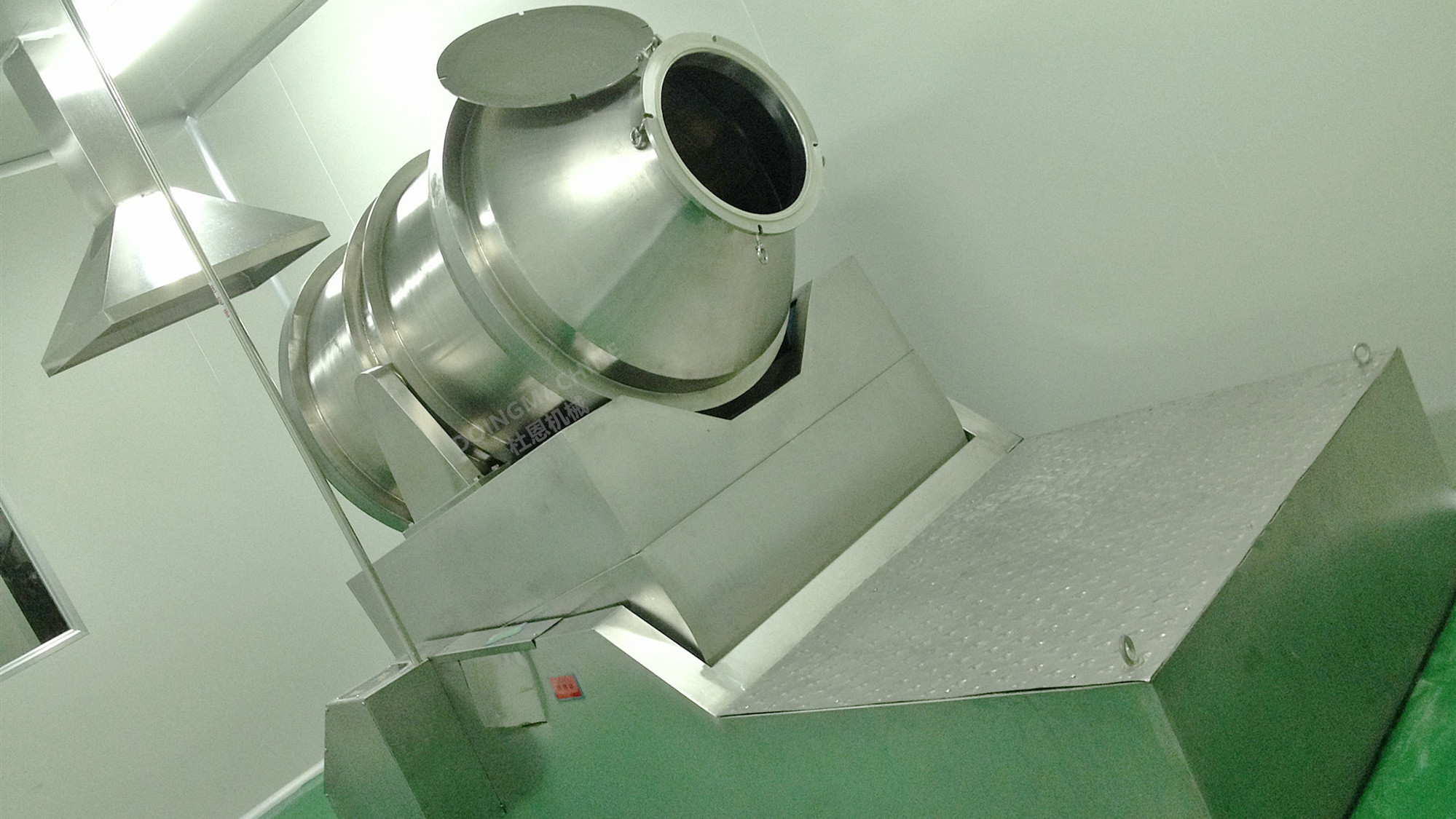

Working principle

EYH series 2D rotary drum batch mixer machine is a novel material mixer extensively used in chemical, metallurgical, food, light and agricultical industries. This mixer can carry out highly even mixing of powders or granules, so that the mixed materials can reach their best effectiveness.

This 2D rotary drum batch mixer machine consists of mixing barrel, swing frame and support frame. The Double cone mixing barrel is mounted on support frame by four rollers which makes the mixing barrel rotate axially. Meanwhile, the crank arm pushes and pulls the mixing barrel back and forth. Axial rotation and rock back and forth happens in a solid two dimensional space. Materials are evenly mixed during rolling and rocking in a very short time.

Technical advantages

1. Mirror polished of inner and outer shell to meet GMP standard.

2. No blind angle in the double-cone shell, no accumulation of materials, efficient and shor mixing time.

3. Mixing uniformity can reach 99%

4. Spiral paddles are welded inside the mixing chamber to enhance mixing

5. Fully integrated motors and controls

6. Can work with vacuum conveyor for automatic and dust-free feeding

7. Mixing chamber volume can be as big as 15000L due to horizontal design for large-scale production.

Main technical parameters

|

Model

|

EYH-300

|

EYH-600

|

EYH-1000

|

EYH-2000

|

EYH-3000

|

EYH-5000

|

|

Volume L

|

300

|

500

|

1000

|

2000

|

3000

|

5000

|

|

Working volume L

|

150

|

250

|

500

|

1000

|

1500

|

2500

|

|

Rotation speed RPM

|

3-12

|

3-12

|

3-12

|

3-12

|

3-12

|

2-8

|

|

Motor power for rotary KW

|

1.1

|

1.5

|

2.2

|

3

|

5

|

7.5

|

|

Motor powder for swing KW

|

0.75

|

1.1

|

1.5

|

2.2

|

4

|

5

|

|

Dimension LxWxH M

|

1.4x1.1x1.4

|

1.8x1.3x1.8

|

2.1x1.4x2.2

|

2.6x1.7x2.5

|

3.0x1.9x2.7

|

3.5x2.3x3

|

|

Weight kg

|

600

|

900

|

1300

|

2000

|

2600

|

4800

|

Detailed Images

Double conic mixing chamber

Discharge valve

Spiral paddles inside the mixing chamber

Swing frame

Packing & Delivery

FAQ

Q: What information should be provided in order to get a proposal or quotation?

A: Our 2D rotary drum batch mixer machine can be customerized. To work out a detailed proposal or quotation, we have to know the following information:

1) Particle size of products to be mixed

2) Bulk density of products to be mixed

3) Mixing volume

4) Construction material:SUS304 or SUS316L

Q: How the machine will be delivered ?

A: The mixer is packed in plywood box for shipping

Hot Searches