- Product Details

- {{item.text}}

Quick Details

-

Operating Speed:

-

24000rpm

-

Product name:

-

Metal Milling water cooled spindle motor

-

application:

-

cnc router metal engraving

-

uages:

-

cnc lathe 5.5kw water cooling spindle motor cnc

-

power:

-

5.5kw

-

voltage:

-

380v

-

Cooling type:

-

Water Cooling

-

Driven:

-

Electric Driven

-

Diameter:

-

120mm

-

Joint of nose:

-

ER25- Diameter 3.175-diameter16

-

speed:

-

240000rpm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

hycnc

-

Maximum Torque:

-

4nm

-

Operating Speed:

-

24000rpm

-

Product name:

-

Metal Milling water cooled spindle motor

-

application:

-

cnc router metal engraving

-

uages:

-

cnc lathe 5.5kw water cooling spindle motor cnc

-

power:

-

5.5kw

-

voltage:

-

380v

-

Cooling type:

-

Water Cooling

-

Driven:

-

Electric Driven

-

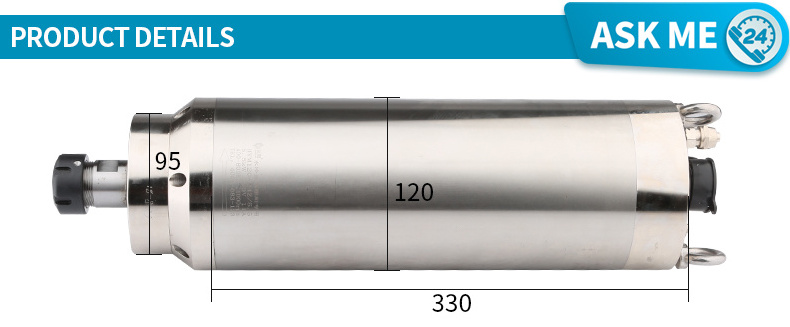

Diameter:

-

120mm

-

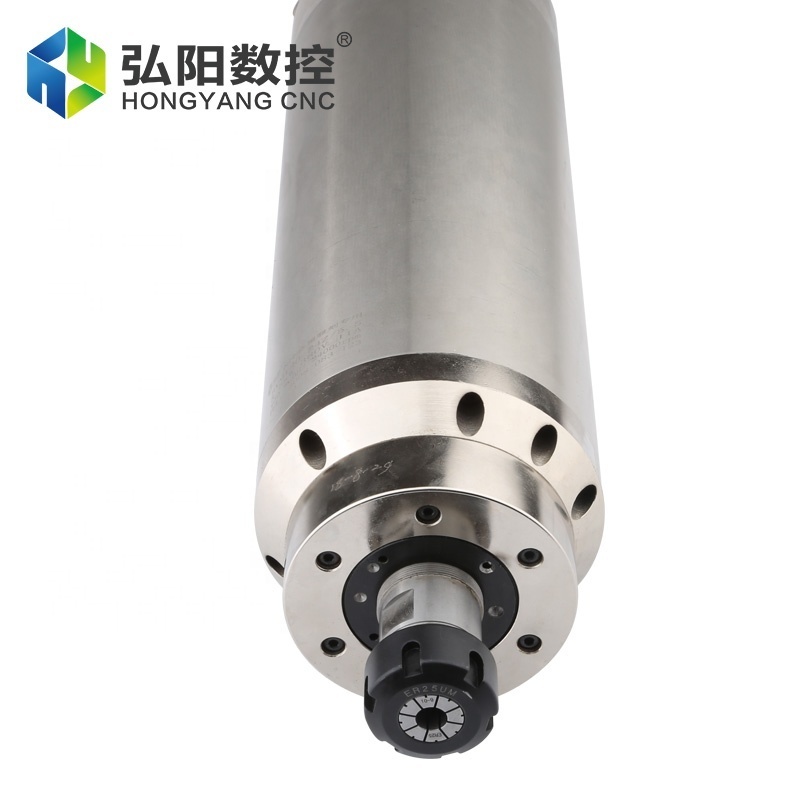

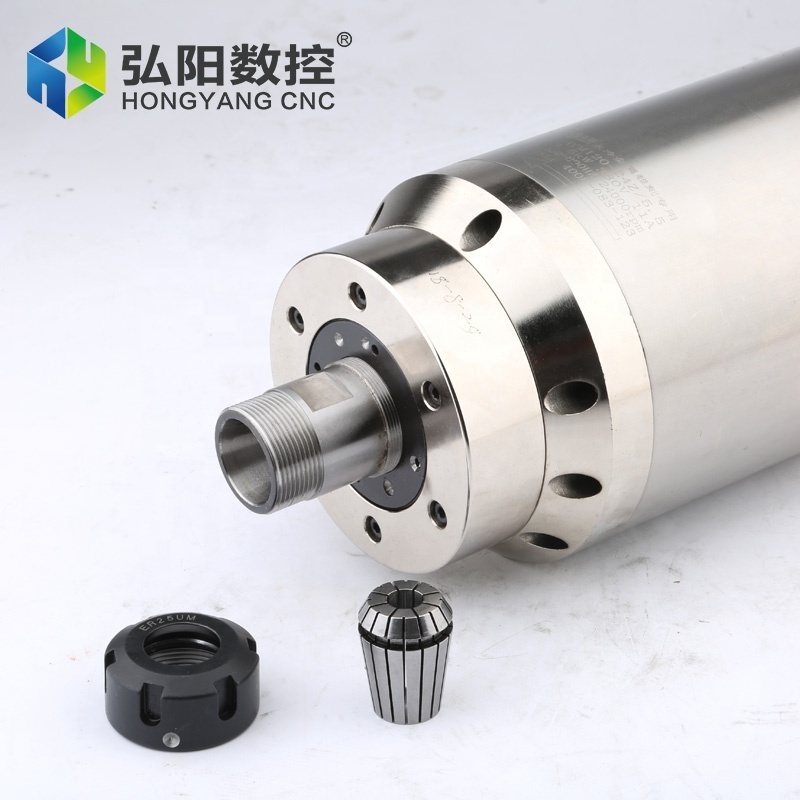

Joint of nose:

-

ER25- Diameter 3.175-diameter16

-

speed:

-

240000rpm

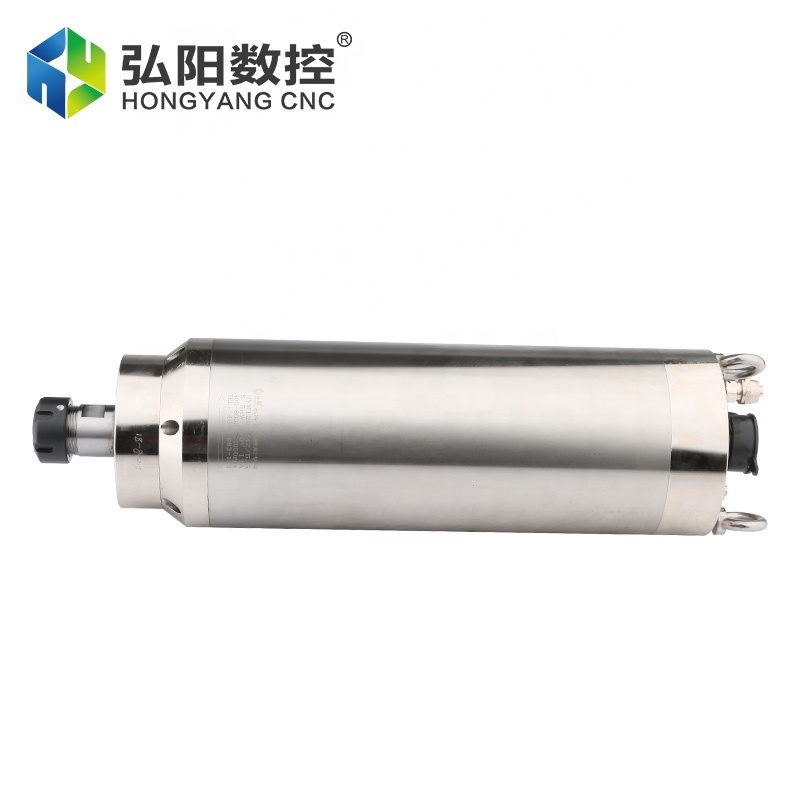

Product name

HYCNC 5.5kw 800hz ER25 permanent power machine tool spindle steel metal cutting milling cnc spindle cnc lathe engraving spindle

Product Description

|

Model

|

HYM120-24Z/5.5

|

Brand

|

HYCNC

|

|

Power

|

5.5kw

|

Frequency

|

800Hz

|

|

Speed

|

24000rpm

|

Voltage

|

380V

|

|

Current

|

11A

|

Cooling method

|

Water cooling

|

Size: 120x400mm (Middle body diameter:120mm;Length:400mm)

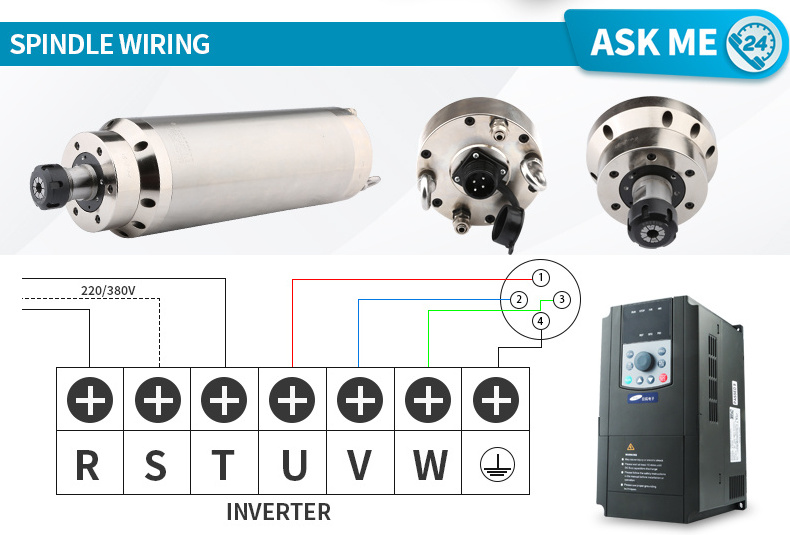

Speed Ways: Through 3-phase output inverter and adjust the inverter frequency to change the spindle speed. Cooling: Water cooling

Power Interface: Optional waterproof air plug. The air plug marked "1 ","2"," 3"," 4", "1 ","2 ","3" were connected to inverter (U, V, W), 4 connected inverter ground.

Power: 5.5kw

Voltage: 220v/380v

Current: 11A

Current: 11A

Frequency: 800Hz

Speed: 0-24000rpm

Diameter(mm): 120

4pcs fully sealed angular contact bearings

Collet: ER25 Clip

Knifediameter:3.175-16

Knifediameter:3.175-16

GreaseLubrication

Main

Application: Main use: Used for carving on wood, bamboo, stone, metal, and also on soft metal surfaces such as

gold, silver, copper, aluminum, and Pb.

1.The received spindle motor will start from the low speed 6000 and increase by 3000 every ten minutes, until after 24000, it can

be used normally. The new spindle needs to be preheated and run-in2.Connect the inverter spindle, three-phase inverter power cord should be soldered in the plug 1 (U), 2 (V), 3 (W) feet, 4 feet

for the ground. After the power is turned on, to observe whether the spindle rotation axis indicates the direction consistent. If

inconsistency should be immediately shut down, replace the inverter and spindle connected two wires of three-phase power supply.

3.Every day before using the spindle must be running at low speed for 15-20 minutes. Clamping the cutters to spindle, collet nuts

,collets,cutters must be clean enough.

be used normally. The new spindle needs to be preheated and run-in2.Connect the inverter spindle, three-phase inverter power cord should be soldered in the plug 1 (U), 2 (V), 3 (W) feet, 4 feet

for the ground. After the power is turned on, to observe whether the spindle rotation axis indicates the direction consistent. If

inconsistency should be immediately shut down, replace the inverter and spindle connected two wires of three-phase power supply.

3.Every day before using the spindle must be running at low speed for 15-20 minutes. Clamping the cutters to spindle, collet nuts

,collets,cutters must be clean enough.

Packing & Delivery

Hot Searches