- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

plastic mould

-

Design software:

-

Most advanced design software

-

Mould base:

-

LKM.HASCO

-

Keyword:

-

Hot runner precision PA66 PPE automotive accessories injection mold

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Mould life:

-

100,000-300,000shots

-

Material:

-

ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT

-

Cavity:

-

Singl / Muti Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Certification:

-

ISO9001:2015

-

Type:

-

plastic mould

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

plastic mould

-

Model Number:

-

plastic mould

-

Design software:

-

Most advanced design software

-

Mould base:

-

LKM.HASCO

-

Keyword:

-

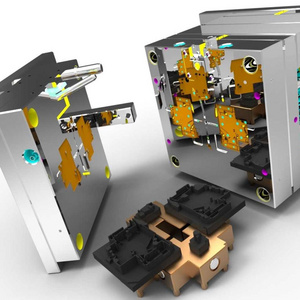

Hot runner precision PA66 PPE automotive accessories injection mold

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Mould life:

-

100,000-300,000shots

-

Material:

-

ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT

-

Cavity:

-

Singl / Muti Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Certification:

-

ISO9001:2015

-

Type:

-

plastic mould

Product Description

|

Product Name

|

Hot runner precision PA66 PPE automotive accessories injection mold plastic injection molding

|

|

Mold Material

|

NAK80,P20,718,718H, S136,1.2343,1.2344, H13,738H, etc

|

|

Plastic Material

|

ABS, PP, PC, PBT,PA, POM, HDPE, TPE,TPR, PU, etc

|

|

Surface Treament

|

Texture, gloss, electroplating, silk printing, polishing, etc

|

|

Drawing Format

|

STEP, STL, X-TIGS, PDF, JPG, etc

|

|

Making Process

|

CNC machining, CNC miling,EDM/wire EDM machining, Plastic Injection Molding

|

|

Quality Assurance

|

lS09001:2015,SGS,ROHS, TUV , etc

|

|

Packing

|

Auto Parts will be packed with carton box and pp bags. Or customized package based on your request.

|

Automotive Roof Cover Mold

Tool Making Process:

CNC machining, EDM/ wire EDM machining

Part Making Process:

Plastic Injection Molding

Mold Material: P20HH

Plastic Material: PP+30%GF

Automotive Bezel Mold

Tool Making Process:

CNC milling, CNC machining, EDM/wire EDM machining

Molds Material: S136 HRC48-52

Plastic Material: P20HH

Favorite features: Great communication, competitive overseas pricing

Molds Material: S136 HRC48-52

Plastic Material: P20HH

Favorite features: Great communication, competitive overseas pricing

1. Request for quotation

You will get a quick quotation after contact us.

2. DFM Report

We will make an free DFM report when reach an agreement.

3. Mold Design

Our professional engineers will design the mold that fit for the molding.

4. Tooling Making

Going through a series of checking steps, we start making the tool

5. T1 Sample Verification

We strictly abide by the requirement of quality first, and send you the sample.

6. Massive Production

The mass production will come into effect when we get your confirmation

7. Post-Processing

We will process the finished products according to your requirements.

8. Assembly

Also then we can assemble the parts according to your needs.

9. Packing

Finally we will send the products by sea or air or your special solutions.

ZhongHesheng Mould is Our mold company has been in the business of plastic injection molding for 21 years, and we pride ourselves on our expertise in molding medical device enclosures, automotive shell casings, and smart appliance housings. With a focus on quality, our engineers work diligently to exceed customer expectations. We understand the importance of precision in mold manufacturing and use cutting-edge technology to deliver high-quality products. At our mold company, we offer a comprehensive range of services from the initial design stage to final production. We aim to deliver the highest quality molds at competitive prices, utilizing our advanced injection molding technology to create the perfect finished product.

Our factory ZhongHesheng Mould covers an area of 7,000 ㎡ and has more than 150+ employees. We are a leading injection molding manufacturer with over 21 years of experience in the industry Our company has complete process capabilities, from design to assembly and packing. We also have strict quality control measures in place for every step of the process.

Our surface treatment capabilities include silk printing, chrome plating, polish, texture, hot stamping, etc. If you need other services, our team can help you and will be your best choice.

Polishing

Texture

Electroplating

FAQs

Q1:How soon can I get a precise quotation?

A1: Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: If I have only samples, how can I start my project?

A2: You can send your samples to us, we can make 3D output data based on your product, and draw the 3D design drawing, and then make a mold.

Q3: How do you guarantee the quality of mass production ?

A3: First: when we complete the mold, we will make the samples to you to check and confirm; after you confirm the final samples, it will be the standard parts. At the beginning of mass production, we will strictly inspect the products according to the standard parts ; Second, we have professional QC for each working shift, QC will check each 3 hours during mass production ; Finally , before shipment , our QC will arrange spot checks.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

A1: Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: If I have only samples, how can I start my project?

A2: You can send your samples to us, we can make 3D output data based on your product, and draw the 3D design drawing, and then make a mold.

Q3: How do you guarantee the quality of mass production ?

A3: First: when we complete the mold, we will make the samples to you to check and confirm; after you confirm the final samples, it will be the standard parts. At the beginning of mass production, we will strictly inspect the products according to the standard parts ; Second, we have professional QC for each working shift, QC will check each 3 hours during mass production ; Finally , before shipment , our QC will arrange spot checks.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

Hot Searches