- Product Details

- {{item.text}}

Quick Details

-

Injection Rate (g/s):

-

10 g/s

-

Injection Weight (g):

-

20 g

-

Screw diameter (mm):

-

20 mm

-

Weight (KG):

-

450 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

70 mm

-

Power (kW):

-

1 kW

Quick Details

-

Ejector Stroke(mm):

-

70 mm

-

Ejector Force(kN):

-

20 kN

-

Theoretical Shot Volume(cm³):

-

0.2 cm³

-

Injection Rate (g/s):

-

10 g/s

-

Injection Weight (g):

-

20 g

-

Screw diameter (mm):

-

20 mm

-

Weight (KG):

-

450 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

70 mm

-

Power (kW):

-

1 kW

laboratory horizontal vertical Precision micro injection molding testing machine

Equipment description:

The machine has been miniaturized and improved for production, with small volume and strong mobility, suitable for classroom teaching and small sample size

In the production.The product includes mold opening and closing parts, sol injection parts, body, heating system, control system and feeding device.with

Simple structure, easy operation, no noise and no pollution;Use 220V voltage, can be used in any place with electricity, not subject to industrial electricity Restrictions.

laboratory horizontal vertical Precision micro injection molding testing machine

Performance Features:

1. Small mold is adopted, which is convenient to make, reasonable in cost and easy to replace

2. AC220V+ pneumatic control + planetary servo system, no oil, no power, small volume

3. PLC human-machine interface (color touch screen), one-button operating system, simple operation and easy maintenance

4. Adopt mechanical and electronic double protection device to ensure safety.

5. Single screw feeding is adopted, which is more fully plasticized than the plunger type structure

laboratory horizontal vertical Precision micro injection molding testing machine

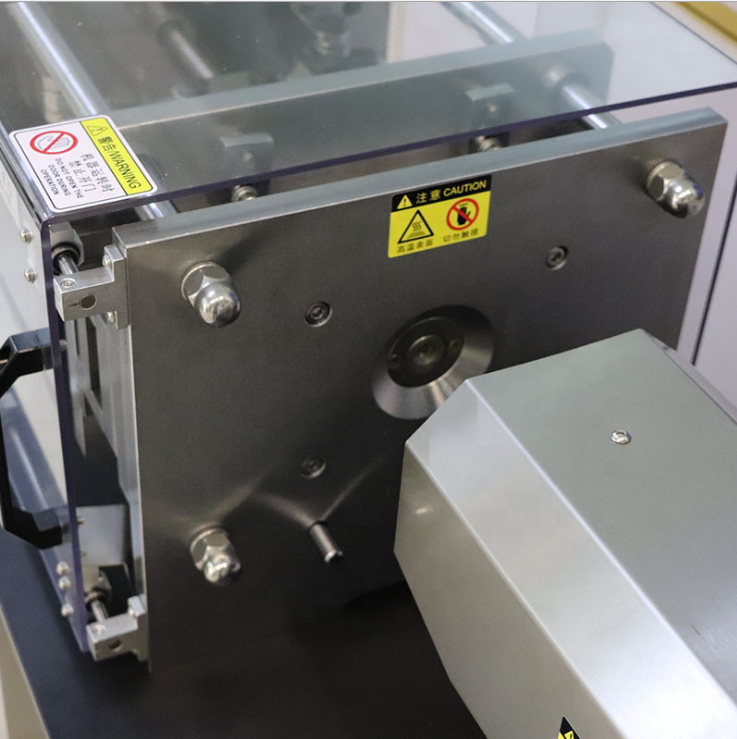

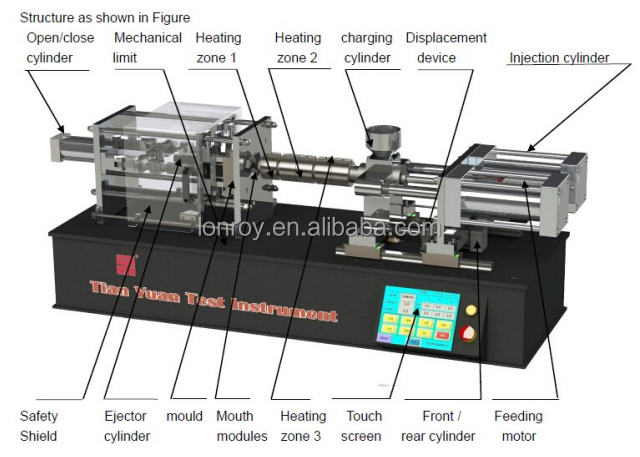

M achine construction

laboratory horizontal vertical Precision micro injection molding testing machine

T echnical parameters

|

main technical parameters |

specification |

|

Loading torque |

105N.M( Servo motor + planetary reducer ) |

|

atmospheric pressure |

≥0.8Mpa |

|

Injection range |

0-80mm |

|

Injection resolution |

0.1mm |

|

0.2L |

|

|

Feeding speed |

0.1-60rpm( Highest 100rpm, After 60rpm, the torque decreases to 50%) |

|

opening stroke |

70mm( Does not contain the mould ) |

|

injection force |

1.8T( Can be increased by a force multiplier system 3.6T) |

|

Maximum emission |

57MPa( Backup system upgraded to 113Mpa) |

|

Maximum injection rate |

25cm 3 ( Less fluidity of the need to customize the force multiplier system ) |

|

clamping force |

2T( Hyperbolic arm clamping device ) |

|

maximum temperature |

One/two/three District 360°C |

|

Temperature Accuracy |

±0.5°C( temperature constant state ) |

|

Power/full load power |

individual event AC 220V±10%; 50HZ ; 2200W ; 10A |

|

screw diameter |

20mm |

|

Setting ring outside diameter |

50mm |

|

Columbine spacing |

280*186mm( center distance ) |

|

Mo u ld size |

360*90*72mm (length * width * thickness) without die |

|

Mould thickness |

0-25mm |

|

boundary dimension |

1700×500×950mm |

|

package size |

1800*700*1100mm |

|

Application Materials

|

Engineering plastic PP, PE, PA, ABS, TPU, PLA, etc |

|

Gross net weight of machine |

420/380kg |