1.

Construction Simplicity

• easier installation of external post-tensioned tendons

2.

Time Savings/Cost Effectiveness

• precast segment to be prefabricated and stored at casting yard while foundation and sub-structure are being built.

• by using efficient erection method and equipment, the rapid installation of viaduct can be achieved.

3.

Quality Control Q - A/QC

• precast segment to be produced in factory-manner condition w/ good quality control.

• minimum interruption natural impacts such as bad weather, rain.

• minimum waste of material

• good precision in production.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Other

-

Design Style:

-

Industrial

-

Type:

-

precast box beam

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BOYOUN

-

Model Number:

-

Formwork System

-

Material:

-

Q235 Steel material

-

Size:

-

Project Drawing

-

Certificate:

-

ISO9001

-

Advantage:

-

Quick Assemble

-

Packing:

-

Standard Sea-transport Packing

-

Accessories:

-

Tie Bolt

-

Performance:

-

Easy Handling

-

Color:

-

Customized

-

Surface treatment:

-

Paint Spraying

-

Process:

-

welding

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training

-

Project Solution Capability:

-

3D model design, total solution for projects

-

Application:

-

Other

-

Design Style:

-

Industrial

-

Type:

-

precast box beam

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BOYOUN

-

Model Number:

-

Formwork System

-

Material:

-

Q235 Steel material

-

Size:

-

Project Drawing

-

Certificate:

-

ISO9001

-

Advantage:

-

Quick Assemble

-

Packing:

-

Standard Sea-transport Packing

-

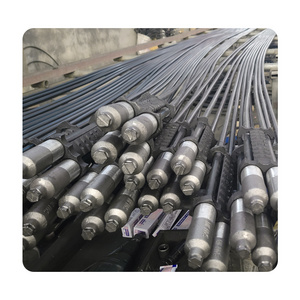

Accessories:

-

Tie Bolt

-

Performance:

-

Easy Handling

-

Color:

-

Customized

-

Surface treatment:

-

Paint Spraying

-

Process:

-

welding

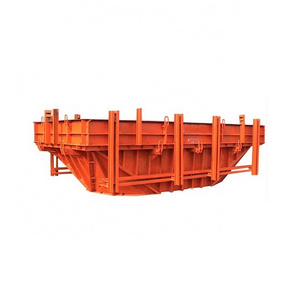

PRODUCT DESCRIPTION

Precast

Segmental

Box Girder Formwork

Precast segmental box girder

Product Paramenters

|

Precast Box Girder Formwork

|

|

|

|

|

||||

|

1

|

Segment length

|

Maximum width 22m (cell number 1, 2, 3 are available)

|

|

|

||||

|

|

Segment length

|

Normally no more than 4m

|

|

|

||||

|

2

|

Standard Configuration

|

External Formwork , Bottom Formwork, Blocking System (Fixed End Formork and Mobile End Formork ), Internal Formwork and Formwork

Trolley |

|

|

||||

|

3

|

Options

|

1 set of standard configuration includes 2 bottom formwork, and the bottom molds can be added as needed

|

|

|

||||

|

4

|

Material

|

Q235B, Q345Steel.

|

|

|

||||

|

5

|

Design time

|

The preliminary technical plan design will take 3 days.

|

|

|

||||

|

|

|

The fabrication drawings will take 5 days to design.

|

|

|

||||

|

6

|

Fabrication

|

The normal duration is about 40 days.

|

|

|

||||

|

7

|

Painting

|

Each formwork is painted three times: a primer, a middle paint, and a top paint. This prevents rust from corroding the formwork.

|

|

|

||||

|

8

|

Delivery

|

Boyoun maintains positive relationships with many logistics companies to ensure prompt delivery of formworks to the port.

|

|

|

||||

|

9

|

Installation on Project site

|

Boyoun can assign one or two engineers to provide technical support at the project site.

|

|

|

||||

WHY CHOOSE US

RELATED PRODUCTS

CERTIFICATIONS AND HONORS

COMPANY PROFILE

Introduction of Shandong Boyoun Industries Co., Ltd.

Shandong Boyoun Heavy Industries Co., Ltd, founded in 2006, is committed to supplying a wide range of formwork for bridge, viaduct and tunnel engineering. The headquarter and main factory are located in Binzhou city of Shandong China, with International Department located in Beijing.

The annual output is more than

75,000

tons, Boyoun has been qualified by

ISO QM

System since its foundation. More than 30 patents have been approved each year. Main products cover: Cantilever Form Traveller, Underslung Form Traveler, Precast Segmental Box Girder Formwork, PC I shape T shape U shape Girder Formwork, Tunnel Lining Trolley, Pier formwork, etc. Besides supplying the formwork, customized services like technical proposals, on-site installation supervision, buying back and rental service can be also provided by Boyoun.

Replying on advanced processing machines, such as laser cutter and automatic welding robot, Boyoun has completed over

1,200

projects Worldwide,including China-Maldives Friendship Bridge in Maldives, Padma Bridge and BRT Dhaka in Bangladesh, Pulau Balang Cable Stayed Bridge and Kendari Cable Stayed Bridge in Indonesia, East Coast Railway in Malaysia, Malaysia MRT 2 and LRT 3, BGC-Ortigas Bridge in Philippines, No.6 Expressway and Tha Chin River Bridge in Thailand, North-South Corridor Project in Singapore, etc.

Painting Workshop

Ready for Painting

Welding Workshop

DELIVERY

CONTACT US

Hot Searches