- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 750 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

AccurL

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6500 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4090*1600*1690mm

-

Year:

-

2020

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Rated Power:

-

7.5kw

-

Control system:

-

Accurl Estun E21s NC Control

-

Cutting thickness:

-

6mm(Carbon steel)

-

Cutting Lenght:

-

4000mm

-

Back Gauge:

-

10-650mm

-

Main Motor:

-

Siemens from Germany Brand

-

Tubing connector:

-

EMB form Germany Brand

-

Weight:

-

6500kg

-

Application:

-

Industrial Metal Cutting

Quick Details

-

Max. Cutting Width (mm):

-

4000

-

Max. Cutting Thickness (mm):

-

4 mm

-

Shearing Angle:

-

2.5

-

Blade Length (mm):

-

3200 mm

-

Backgauge Travel (mm):

-

20 - 750 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

AccurL

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6500 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4090*1600*1690mm

-

Year:

-

2020

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Rated Power:

-

7.5kw

-

Control system:

-

Accurl Estun E21s NC Control

-

Cutting thickness:

-

6mm(Carbon steel)

-

Cutting Lenght:

-

4000mm

-

Back Gauge:

-

10-650mm

-

Main Motor:

-

Siemens from Germany Brand

-

Tubing connector:

-

EMB form Germany Brand

-

Weight:

-

6500kg

-

Application:

-

Industrial Metal Cutting

Products Description

Hydraulic CNC Shearing Machine for Metal Shear Cutting Machine

ACCURL MS7 Hydraulic Swing Beam Shear can cut all kind of metal sheet to maintain the highest production capacity with maximum precision and quality.

More than just cutting; NC MS7 is developed by expert engineers of ACCURL reflects innovative technology with all aspects of it.

Standard Equipment:

1. Wear resistant blades for Top blade 4 cutting edge and Bottom blade 4 cutting edge.

2. Portable foot pedal is eligible for single and automatic cutting.

3. ESTUN E21s NC controller System.

4. NC controlled motorized backgauge system.

5. 600 mm motorized back gauge system with 0.1 mm accuracy.

6. Front support arms with T slot, ruler and flip stop.

7. Squaring arm.

8. Scales with metric and inches.

9. Cutting line illumination and shadow line.

10. Central lubrication system.

11. Front finger protection guard appropriate to CE norms, 1 m left side collapsible and switch protected.

12. Rear sliding plates.

13. Front sliding plates with ball bearings on the table.

2. Portable foot pedal is eligible for single and automatic cutting.

3. ESTUN E21s NC controller System.

4. NC controlled motorized backgauge system.

5. 600 mm motorized back gauge system with 0.1 mm accuracy.

6. Front support arms with T slot, ruler and flip stop.

7. Squaring arm.

8. Scales with metric and inches.

9. Cutting line illumination and shadow line.

10. Central lubrication system.

11. Front finger protection guard appropriate to CE norms, 1 m left side collapsible and switch protected.

12. Rear sliding plates.

13. Front sliding plates with ball bearings on the table.

Details Images

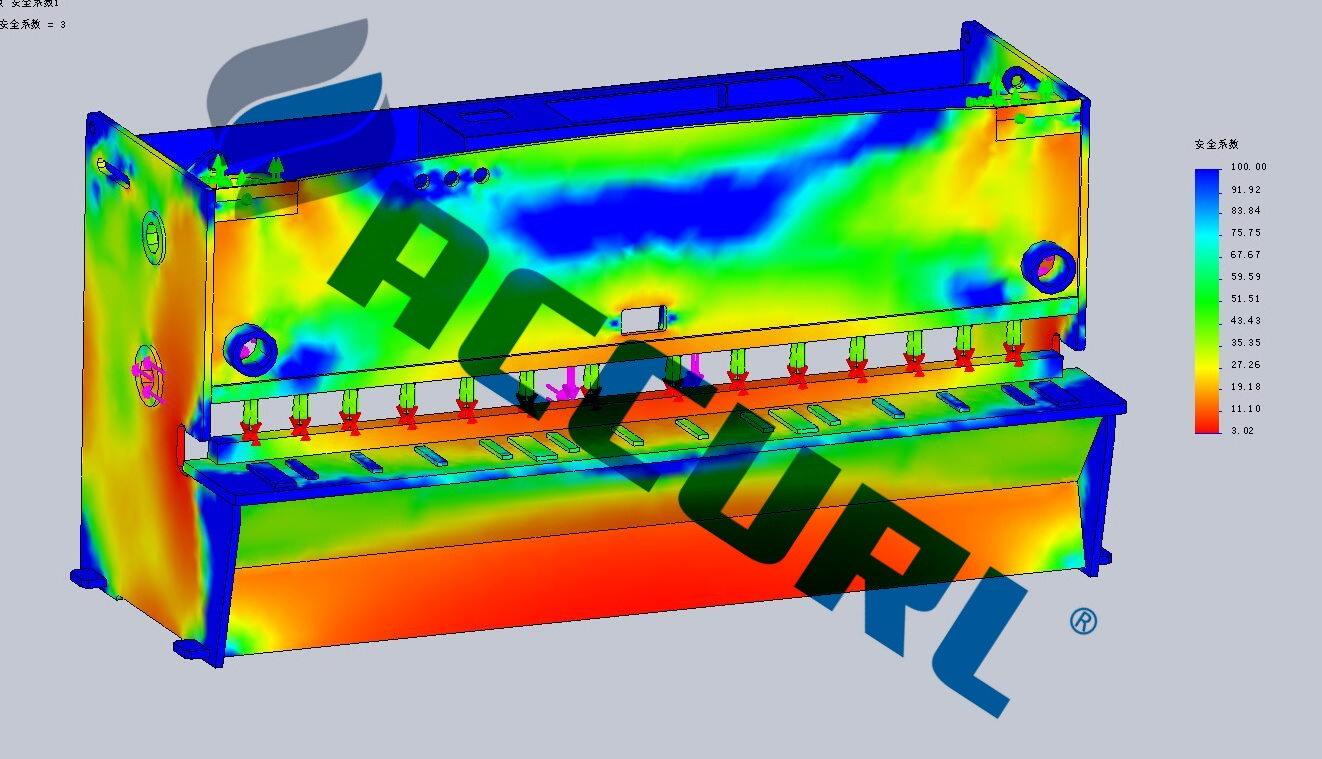

MACHINE DESIGN

ACCURL Shears features a rigid frame for min deflection under the load. The frame steels are German origin and designed using SOLIDWORKS 3D programming and made with quality steel Improved Q235 using the latest technology.

Feature:

* The machine welding is made by welding plant and welding robots.

* After the welding,we make stress relief process by vibration system.

* After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy.

* Allreference surfaces and connection holes are machined.

* The machine welding is made by welding plant and welding robots.

* After the welding,we make stress relief process by vibration system.

* After the stress relief process machine frame goes to CNC 5 axes machining centers for accuracy.

* Allreference surfaces and connection holes are machined.

SHEARING PROCESS

Perfect design in every aspect; By choosing the new and improved CNC Swing Beam Shears MS7 Series, you will bring modern-day technology to your company with maximum

safety, high accuracy and unique ease of use.

Blade gap, cutting length are all adjusted based on material selection and thickness automatically.

safety, high accuracy and unique ease of use.

Blade gap, cutting length are all adjusted based on material selection and thickness automatically.

QUALITY

ACCURL, known as one of the top worldwide manufacturers in the sheet metal industry,

proudly announces its latest shear model to the market,Variable Rake Hydraulic Shears.

The critical parts of the Accurl shearing machine are manufactured in Germany.The carefully selected components come from long-term partners. We rely on our quality and therefore give our shears a 3-year warranty.

proudly announces its latest shear model to the market,Variable Rake Hydraulic Shears.

The critical parts of the Accurl shearing machine are manufactured in Germany.The carefully selected components come from long-term partners. We rely on our quality and therefore give our shears a 3-year warranty.

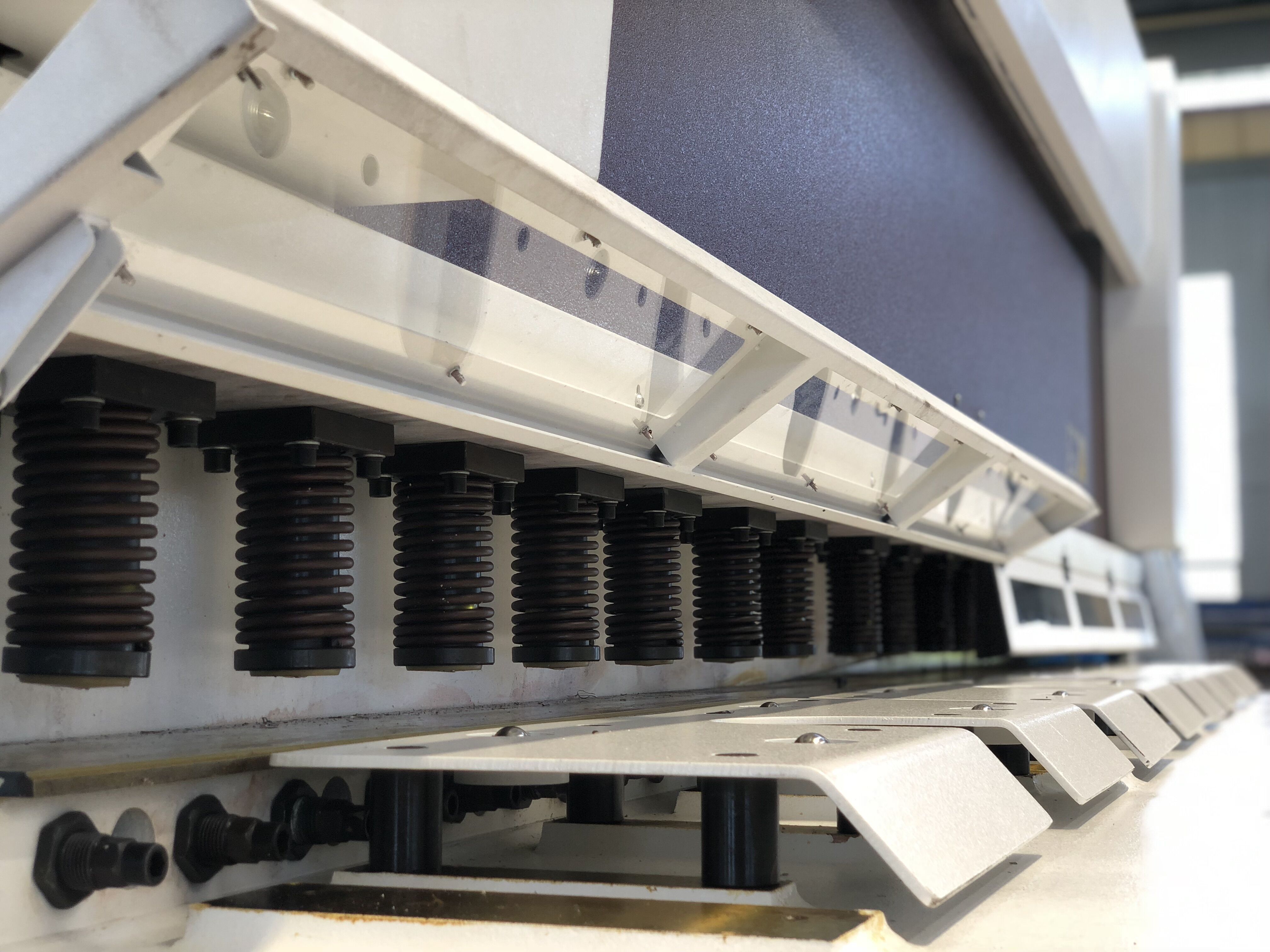

PNEUMATIC SHEET SUPPORT SYSTEM

Monobloc Panel Type support system:

Avoids hanging down the wide and thin sheets via pneumatic table support and provides more precise cuts.

Avoids hanging down the wide and thin sheets via pneumatic table support and provides more precise cuts.

CNC CONTROL UNIT

* 7" widescreen TFT Colour LCD display * Back / front gauge control

* Panel based housing

* Retract function

* Cutting angle and gap control

* Stroke length limitation

* Manual movement of all axes

* Force control

* Return to Sender function

* Program memory for 100 programs

* Sheet support system.

* Panel based housing

* Retract function

* Cutting angle and gap control

* Stroke length limitation

* Manual movement of all axes

* Force control

* Return to Sender function

* Program memory for 100 programs

* Sheet support system.

DAC360T CNC Control Unit

ACCURL has chosen the very powerful new generation DELEM DAC360T offers an higher level of efficiency in programming and control of guillotine. The winning MADE in Netherlands design and the high quality of all the construction details, guarantee prestigious performances and long product life.

SPECIFCATIONS

|

Type |

Cut Thickness

mm |

mm |

Shear Angle

Degree |

SPM min-1 |

mm |

Throat Depth

mm |

Main Motor

kw |

|

MS7-4×2500

|

4

|

2500

|

1°30'

|

≥ 22

|

600

|

100

|

5.5

|

|

MS7-4×3200

|

4

|

3200

|

1°30'

|

≥ 18

|

600

|

100

|

7.5

|

|

MS7-4×4000

|

4

|

4000

|

1°30'

|

≥ 12

|

600

|

100

|

7.5

|

|

MS7-6×2500

|

6

|

2500

|

1°30'

|

≥ 16

|

600

|

120

|

7.5

|

|

MS7-6×3200

|

6

|

3200

|

1°30'

|

≥ 12

|

600

|

120

|

7.5

|

|

MS7-6×4000

|

6

|

4000

|

1°30'

|

≥ 10

|

600

|

120

|

7.5

|

|

MS7-6×6000

|

6

|

6000

|

1°30'

|

≥ 7

|

600

|

120

|

11

|

|

MS7-8×2500

|

8

|

2500

|

1°30'

|

≥ 14

|

600

|

120

|

7.5

|

|

MS7-8×3200

|

8

|

4000

|

1°30'

|

≥ 12

|

600

|

120

|

7.5

|

|

MS7-8×4000

|

8

|

3200

|

1°30'

|

≥ 10

|

600

|

120

|

11

|

|

MS7-10×3200

|

10

|

3200

|

1°50'

|

≥ 12

|

600

|

120

|

11

|

|

MS7-10×4000

|

10

|

6000

|

1°50'

|

≥ 6

|

600

|

120

|

18.5

|

|

MS7-12×2500

|

12

|

2500

|

2°

|

≥ 10

|

800

|

170

|

18.5

|

|

MS7-12×3200

|

12

|

3200

|

2°

|

≥ 9

|

800

|

170

|

18.5

|

|

MS7-12×4000

|

12

|

4000

|

1°80

|

≥ 8

|

800

|

170

|

18.5

|

|

MS7-12×6000

|

8

|

6000

|

2°

|

≥ 4

|

800

|

320

|

30

|

|

MS7-16×2500

|

16

|

2500

|

2°9'

|

≥ 9

|

800

|

315

|

18.5

|

|

MS7-16×3200

|

16

|

3200

|

2°

|

≥ 8

|

800

|

320

|

18.5

|

|

MS7-16×4000

|

16

|

4000

|

2°

|

≥ 7

|

20-1000

|

320

|

18.5

|

|

MS7-16×6000

|

16

|

6000

|

2°

|

≥ 4

|

20-1000

|

320

|

22

|

|

MS7-20×3200

|

20

|

3200

|

2°30'

|

≥ 5

|

1000

|

320

|

30

|

|

MS7-20×6000

|

20

|

6000

|

2°30'

|

≥ 4

|

1000

|

150

|

55

|

|

MS7-25×2500

|

25

|

2500

|

3°

|

≥ 5

|

1000

|

325

|

37

|

|

MS7-25×3200

|

25

|

3200

|

3°

|

≥ 5

|

1000

|

325

|

37

|

|

MS7-32×2500

|

32

|

2500

|

3°30'

|

≥ 4

|

1000

|

350

|

45

|

|

MS7-32×3200

|

32

|

3200

|

3°30'

|

≥ 4

|

1000

|

350

|

45

|

Related Products

Hot Searches