Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Voltage:

-

Customized

-

Weight:

-

3000 KG

-

Usage:

-

Plastic Extrusion

-

Automatic Grade:

-

High Automation

-

Processing Type:

-

Extrusion Process

-

Inverter:

-

ABB Inverter

-

Cooling way:

-

Recycling Water Cooling

-

Product Application:

-

House Decorating Ect

-

Motor brand:

-

SIENEMS BEIDE

-

Screw:

-

38CrMoAIA

-

Control:

-

SIEMENS PLC+Touch Screen

-

Feature:

-

High Production Efficiency

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

70 rpm

-

Place of Origin:

-

China

-

Voltage:

-

Customized

-

Weight:

-

3000 KG

-

Usage:

-

Plastic Extrusion

-

Automatic Grade:

-

High Automation

-

Processing Type:

-

Extrusion Process

-

Inverter:

-

ABB Inverter

-

Cooling way:

-

Recycling Water Cooling

-

Product Application:

-

House Decorating Ect

-

Motor brand:

-

SIENEMS BEIDE

-

Screw:

-

38CrMoAIA

-

Control:

-

SIEMENS PLC+Touch Screen

-

Feature:

-

High Production Efficiency

Products Description

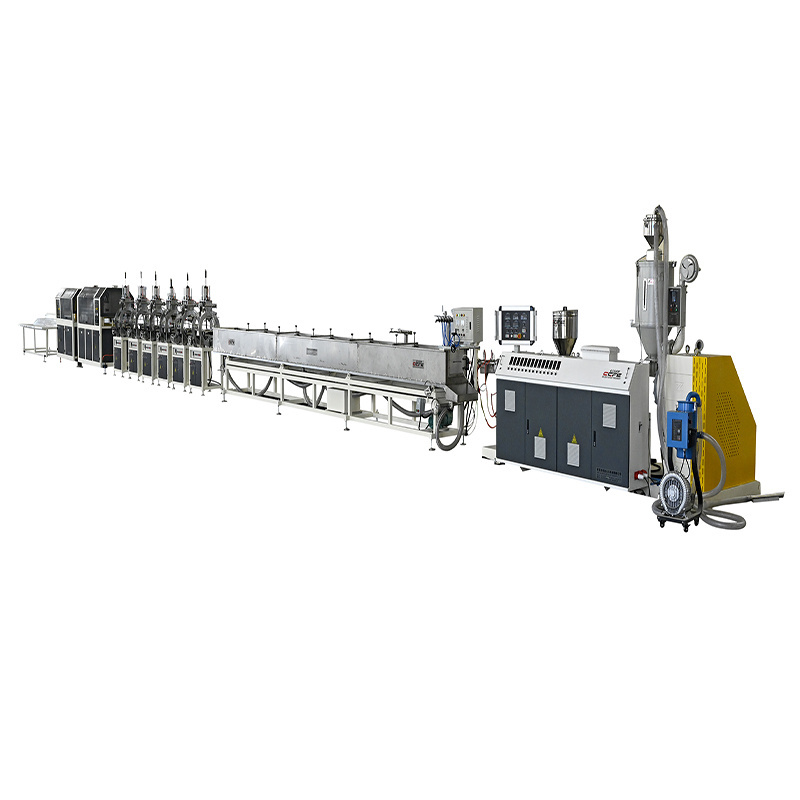

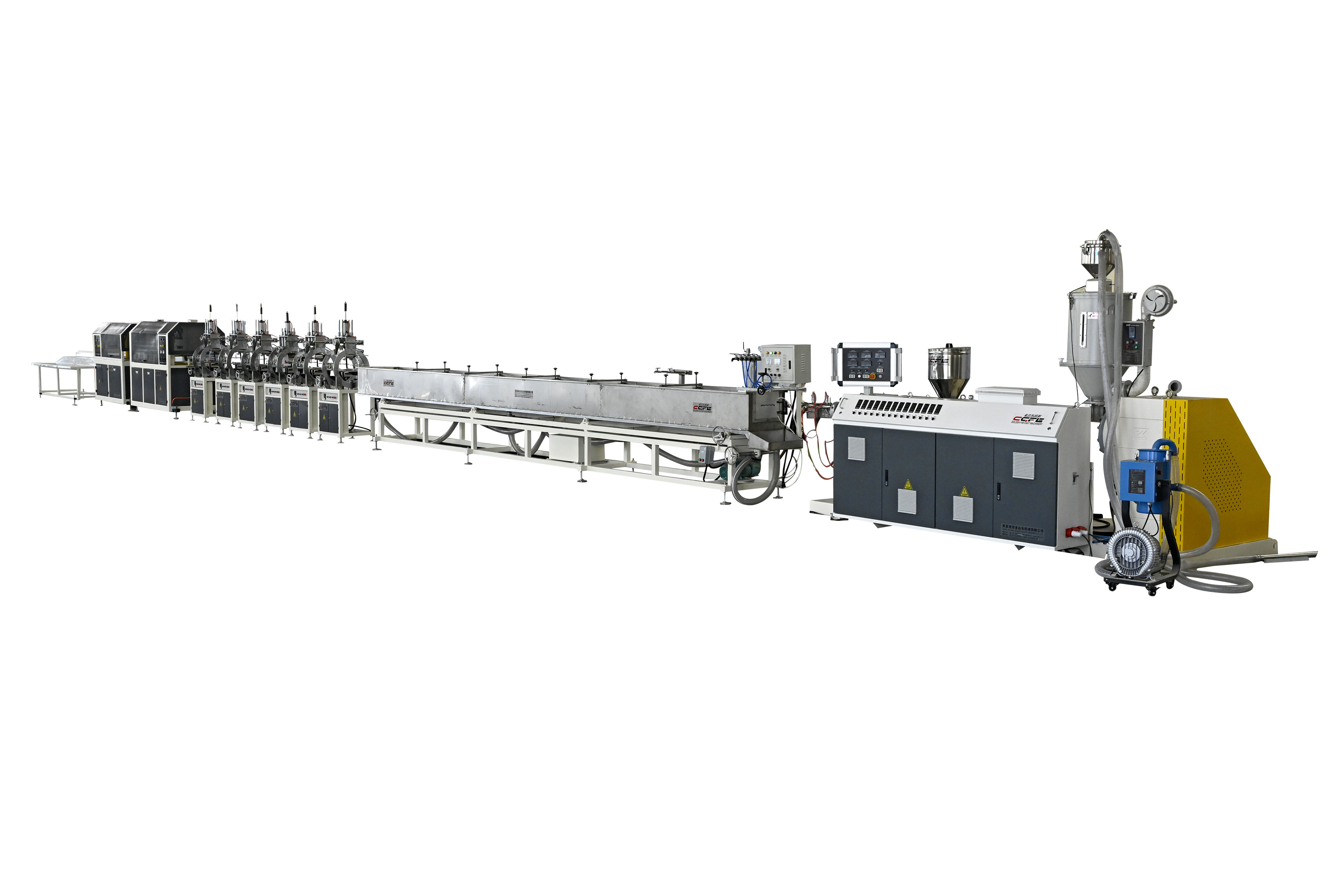

PS Charcoal Louver Panel/Photo Frame Production Line

Main Components

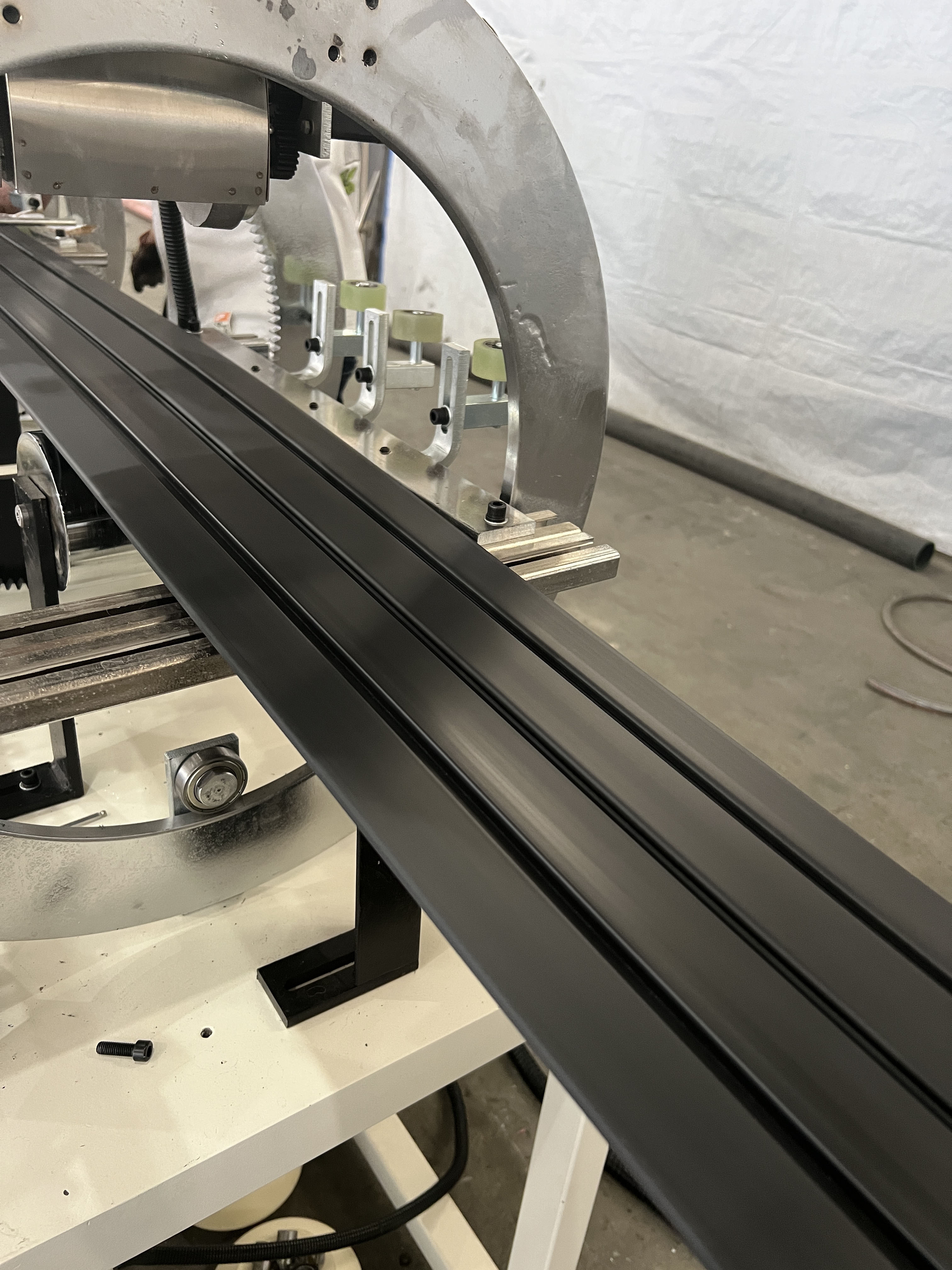

B.

Extrusion mold

(customized)

Tank length

:8.5-10m

Cooling method: Water immersion

Easy for adjustment and installation of hot-stamping rollers and embossing rollers.

E. Haul-off machine with rotary encoder

Speed control: ABB inverter

Haul-off speed: 0.5-5m/min

E. Cutting machine

Cutting power

: 2.2kw

E. Automatic stacker

Stacker length: 3000mm

Material: Stainless steel

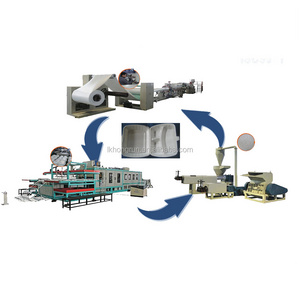

Processing Flow

raw material mixing → extruder → cooling tank

→Hot stamping

→

haul-off → cutting machine

→

stacker

Applications

●photo frame

●interior decoration panel

●charcoal louvers

|

Model

|

SJ90/28

|

SJ100/28

|

SJ120/28

|

|

Motor power

|

45KW

|

45KW

|

75KW

|

|

Product size

|

120*30mm

|

230*30mm

|

300*30mm

|

|

Water tank length

|

8.5m

|

8.5m

|

10m

|

Surface embossing rollers (customized)

Hot-stamping rollers and films

(customized)

PS granules and foam agent (raw material formula will be provided)

Advantages

●simple operation and high output

●high quality standard

●highly automatic and mechanized, energy saving and environmental-friendly

Pre-sales and after sales service

24/7 Online service

1. 24 hours online reply

2. Factory design and machine layout design for free

3. Product formula provided for free

3. Product formula provided for free

Machine production inspection

1. Supervise the machine quality all the time.

2. Inform any new progress of the machines.

3. Test machines by official QC and take machine pictures and videos.

3. Test machines by official QC and take machine pictures and videos.

Machine installation guidance

1. Provide machine installation guidance

2. Provide professional engineer field installation.

3. Provide long-term technical guide and service.

3. Provide long-term technical guide and service.

Technology Corporation

Hot Searches