- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Neutral or OEM

-

Model Number:

-

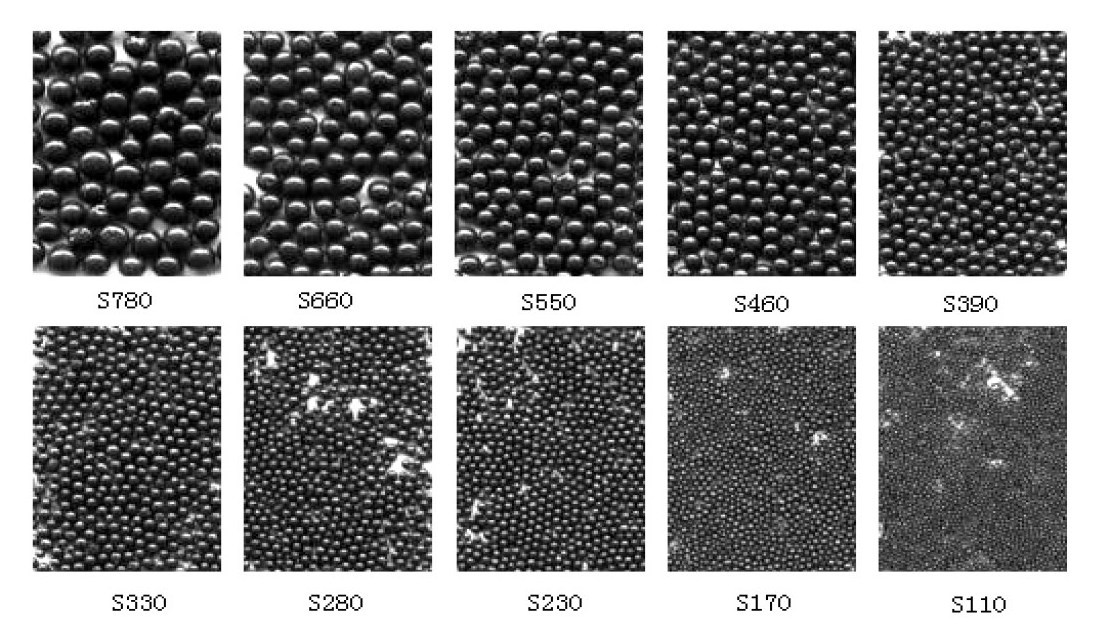

S110-S780

-

Usage:

-

Sandblasting, Polishing Workpiece

-

Material:

-

Alloy Steel

-

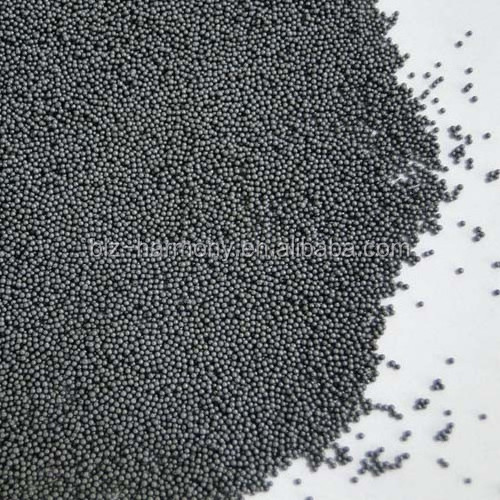

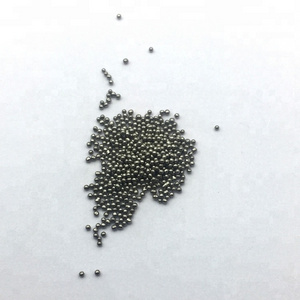

Shape:

-

Spherical

-

Certificate:

-

ISO9001:2008

-

Sample:

-

200g

-

Density:

-

7.4g/cm3

-

Lead Time:

-

10 to 15 days

-

Hardness:

-

HRC 40-66

-

Metallographical Structure:

-

Even Tempered Martensitere

Quick Details

-

Type:

-

blasting media

-

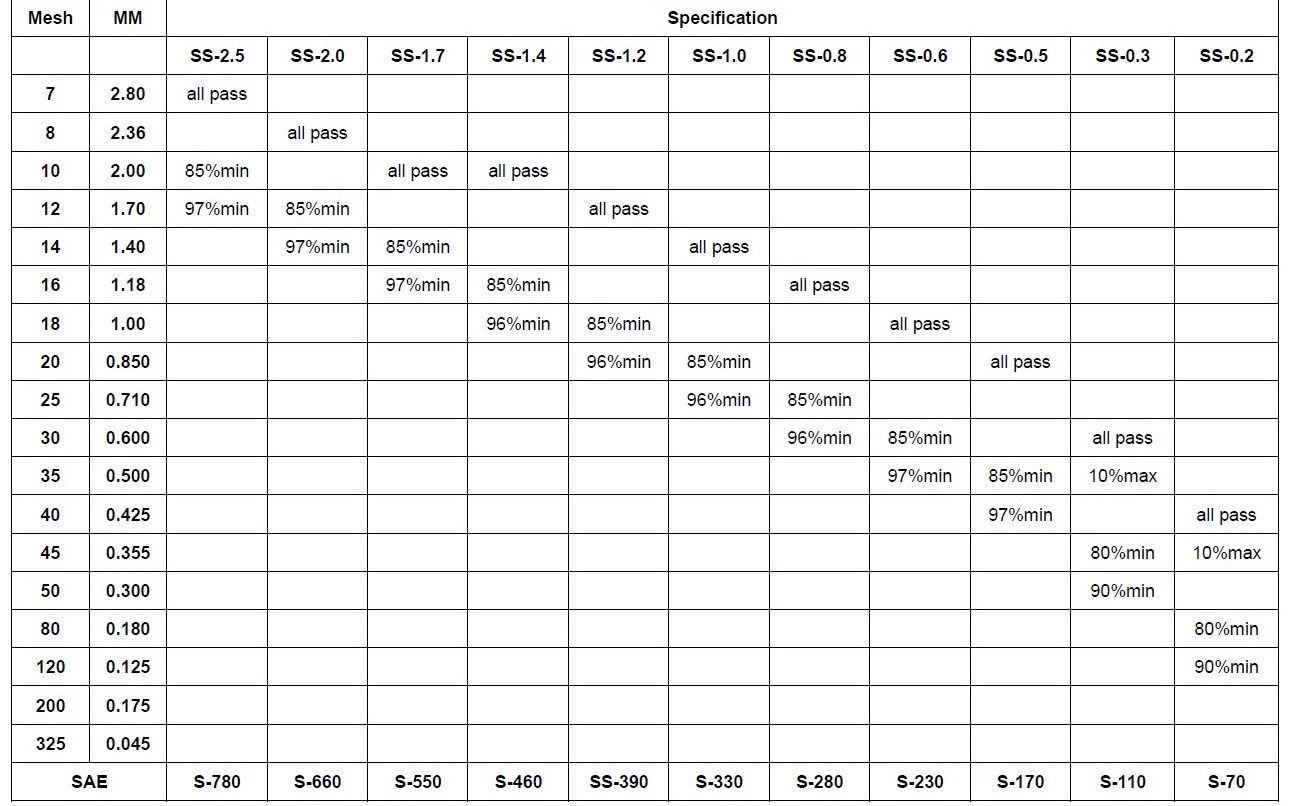

Abrasive Grain Sizes:

-

0.045mm - 2.80mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Neutral or OEM

-

Model Number:

-

S110-S780

-

Usage:

-

Sandblasting, Polishing Workpiece

-

Material:

-

Alloy Steel

-

Shape:

-

Spherical

-

Certificate:

-

ISO9001:2008

-

Sample:

-

200g

-

Density:

-

7.4g/cm3

-

Lead Time:

-

10 to 15 days

-

Hardness:

-

HRC 40-66

-

Metallographical Structure:

-

Even Tempered Martensitere

Product Details

STEEL SHOT /STEEL GRIT

------ Look Through BH Steel shot ------

|

Product

|

Steel shot , Steel grit , Cut wire shot ,etc

|

|

Size

|

Steel shot : S70,S110,S130,S170,S230,S280,S330,S390,S460,S550,S660,S780,S930,etc

Steel grit : G14,G16,G18,G25,G40,G50,G80,G120,etc

Cut wire shot : 0.5mm,1.0mm,1.5mm,2.0mm ,etc

|

|

Standard

|

EN12413, ISO9001:2008

|

|

Micro structure

|

Tempered Martensite or Sorbite

|

|

Hardness

|

HRC 40-65

|

|

Field

|

Cement plant , Mining , Power station , Chemical industries ,etc

|

|

MOQ

|

1 ton

|

|

Lead Time

|

In 15 days for quantity under 100 tons

|

|

Testing

|

Size testing ,Hardness testing ,Chemical composition testing

|

|

Free Sample

|

Available upon request

|

------ Technical Data of Regular Products ------

|

Chemical Composition

|

|

|

|

|

||||

|

C

|

0.85% - 1.20%

|

|

|

|

||||

|

Mn

|

0.60% - 1.20%

|

|

|

|

||||

|

Si

|

0.40% - 1.20%

|

|

|

|

||||

|

S

|

≤ 0.05%

|

|

|

|

||||

|

P

|

≤ 0.05%

|

|

|

|

||||

|

Hardness

|

HRC

40-50 |

HRC

42-50 |

HRC

56-60 |

HRC

63-66 |

||||

|

Hardness Deviation

|

Max Deviation ±3.00HRC

|

|

|

|

||||

|

Metallographical Structure

|

Even Tempered Martensitere

|

|

|

|

||||

|

Min Density

(can be determined by alcoholic displacement) |

7.4g/㎝³

|

|

|

|

||||

------ Our Workshop ------

------ Production Process of Regular Products ------

------ Strict Quality Inspection ------

------ Application of Steel shot

------

|

Steel Shot

|

Applications

|

|

SS-2.5

SS-2.0 |

Sand and rusts removing of large-sized cast iron, cast steel, steel structures, large-sized forging and surface treatment of

oxidized workpieces. |

|

SS-1.7

SS-1.4 |

Sand-removing of large and medium sized castings, deoxidization of forgings, heat-treated pieces, steel plates, steel pipes,

sections and steel structures, surface treatment before plating. |

|

SS-1.2

SS-1.0 |

Sand-removing of small and medium sized castings, rust-removing and intensification of forgings, heat-treated pieces, steel

plates, steel pipes, sections and steel structures, surface treatment before plating, cutting of rocks. |

|

SS-0.8

SS-0.6 |

Sand-removing and deoxidization of small-sized castings, forgings, heat-treated pieces, aluminum-copper alloy castings, steel

plates, steel pipes, sections and steel structures, surface intensification of springs and chains, cutting of rocks, grinding processing. |

|

SS-0.5

SS-0.3 |

Sand-removing and rust-cleaning of alloy castings, thin plates, strip steel, and small-sized stainless steel castings,

intensification of springs, surface treatment before plating, improving roughness, enhancing adhesiveness. |

Service Details

------ Professional Packing ------

Similar Products

Please click the picture for details about the similar products.

About Biz-Harmony

------ Why Choose Us ------

Assurance Measures

------ Leave All Your Worries Behind ------

Contact Us

Hot Searches