- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HuaYang

-

Voltage:

-

380V 50Hz 3phases

-

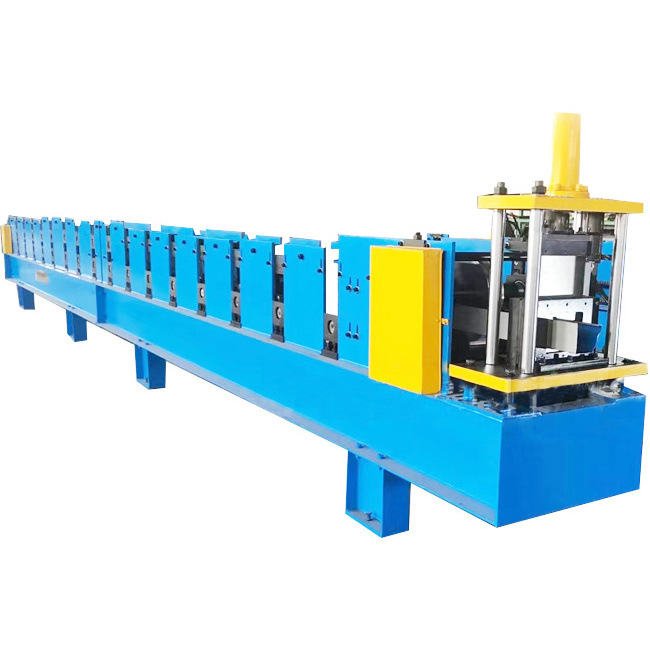

Dimension(L*W*H):

-

7800*1200*1000mm

-

Weight:

-

5000 kg

-

Product name:

-

manufacture metal down pipe making machine price pipe forming machine

-

Raw material:

-

Aliminum coil, GI,PPGI

-

Control system:

-

PLC computer control

-

Roller material:

-

45#steel Chrome Plated

-

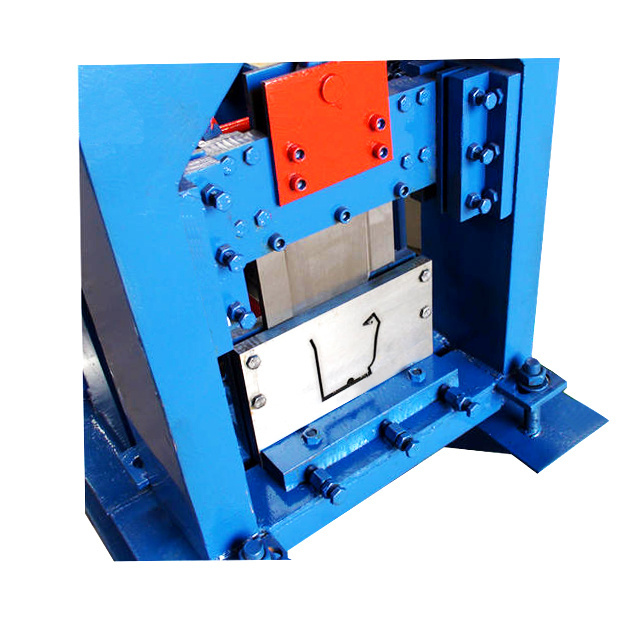

Cutting blade material:

-

Cr 12 High Grade Steel

-

Production speed:

-

12-14m/min

-

Diameter of active shafts:

-

52mm

-

Frame:

-

350H steel

-

structure panel thickness:

-

20mm

-

After-sales Service Provided:

-

Online support

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

12-14m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HuaYang

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7800*1200*1000mm

-

Weight:

-

5000 kg

-

Product name:

-

manufacture metal down pipe making machine price pipe forming machine

-

Raw material:

-

Aliminum coil, GI,PPGI

-

Control system:

-

PLC computer control

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Production speed:

-

12-14m/min

-

Diameter of active shafts:

-

52mm

-

Frame:

-

350H steel

-

structure panel thickness:

-

20mm

-

After-sales Service Provided:

-

Online support

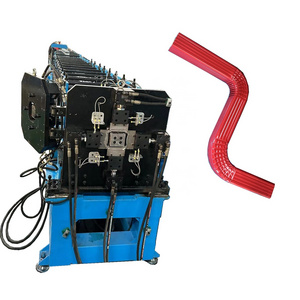

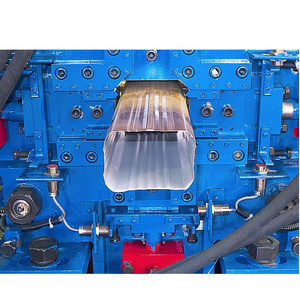

The gutter machine

fully automatically produces half round gutters and rectangular gutters in different lengths and sizes.

Alongside the standard gutter profiles, custom shapes can also be produced depending on the roll set. A visualized touchscreen display allows for easy operation of the machine. The entered parameters can be saved separately for each gutter profile, enabling quick retooling. Selected from the display, all sheet metal side guides and roll sets are set to the correct positions according to the standard gutter size (5K 6K 7K 8K). Since all materials behave differently in the manufacturing process,material-specific values can also be saved in the program.

Alongside the standard gutter profiles, custom shapes can also be produced depending on the roll set. A visualized touchscreen display allows for easy operation of the machine. The entered parameters can be saved separately for each gutter profile, enabling quick retooling. Selected from the display, all sheet metal side guides and roll sets are set to the correct positions according to the standard gutter size (5K 6K 7K 8K). Since all materials behave differently in the manufacturing process,material-specific values can also be saved in the program.

PRODUCT DISPLAY

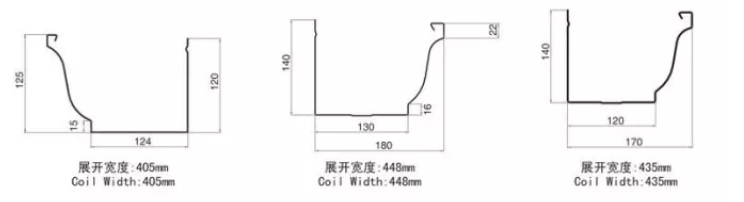

Gutter Profile

Product Details

|

Forming speed

|

About 15-20m/min

|

|

|

|

|

Hydraulic cutting

|

Controlled by PLC

|

|

|

|

|

PLC

|

DELTA, TAIWAN / Mitsubishi, Japan

|

|

|

|

|

Material of cutting blade

|

Cr12Mov, quenching 58-62℃

|

|

|

|

Key benefits

* High flexibility through quick, easy retooling. (the machine can be converted from nominal size 333 to 250 in approx. 5 min).

* During production of 2 m gutters, 2 strips can be manufactured at the same time.

* Roll sets can also be added later at minimal cost to further extend your range of products.

* Large production volumes and extremely short retooling times.

* Negligible to no stock keeping of finished gutters.

* Minimal labor costs through simple one-man operation.

* Remote maintenance for quick and easy troubleshooting.

* Modern recipe management by use of a touchscreen display.

* Equipped with all safety devices incl. safety guards, light curtains, etc.

These materials can be processed: Aluminium, steel, titanium zinc, zinc, pre-weathered titanium zinc, Uginox, Ugitop, copper,coated steel

* High flexibility through quick, easy retooling. (the machine can be converted from nominal size 333 to 250 in approx. 5 min).

* During production of 2 m gutters, 2 strips can be manufactured at the same time.

* Roll sets can also be added later at minimal cost to further extend your range of products.

* Large production volumes and extremely short retooling times.

* Negligible to no stock keeping of finished gutters.

* Minimal labor costs through simple one-man operation.

* Remote maintenance for quick and easy troubleshooting.

* Modern recipe management by use of a touchscreen display.

* Equipped with all safety devices incl. safety guards, light curtains, etc.

These materials can be processed: Aluminium, steel, titanium zinc, zinc, pre-weathered titanium zinc, Uginox, Ugitop, copper,coated steel

Customer Feedback

Customer praise

RELATED PRODUCTS

COMPANY PROFILE

Customer Visit

Hot Searches