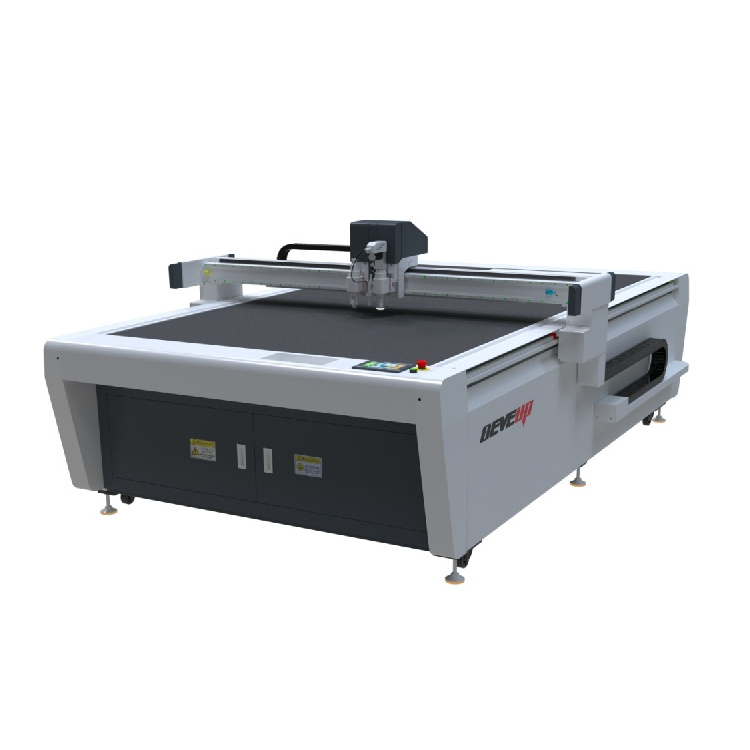

Deveup foam cutting machine features advanced oscillating knife cutting technology. It is widely used in packaging, crafts, toy manufacturing, advertising, and other industries. Only need to transfer the designed graphics to the computer, CNC oscillating knife cutting machine can automatically and accurately cut a variety of foam materials, such as EPE, EVA, XPE, IXPE silicone and other foam materials. No need for molds, high processing accuracy, high efficiency, neat and smooth cutting edges, no smoke and smell, no burning and yellow edge, to meet the high quality cutting requirements of complex graphics.

- Product Details

- {{item.text}}

Quick Details

-

Max.Product Size(H)(mm):

-

110 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Deveup

-

Year:

-

2023

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

3300x2270x1300

-

Control System:

-

DSP

-

Power (kW):

-

11

-

Weight (KG):

-

1400 KG

-

Cutting precision:

-

± 0.1mm

-

Command system:

-

AI, PLT, DXF, DWG

Quick Details

-

Cutting Speed(m/min):

-

0 - 30 m/min

-

Max.Product Size(L)(mm):

-

2500 mm

-

Max.Product Size(W)(mm):

-

1600 mm

-

Max.Product Size(H)(mm):

-

110 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Deveup

-

Year:

-

2023

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

3300x2270x1300

-

Control System:

-

DSP

-

Power (kW):

-

11

-

Weight (KG):

-

1400 KG

-

Cutting precision:

-

± 0.1mm

-

Command system:

-

AI, PLT, DXF, DWG

Products Description

DEVEUP CNC OSCILLATION KNIFE CUTTING MACHINE FOR FOAMS

Specification

|

Model

|

FV1216 FV1625 FV2030

|

|

Working Size

|

1200 x 1600mm 1600 x 2500mm 2000 x 3000mm

|

|

Applicable Industries

|

EVA, EPE, EPP, PE, XPE, IXPE, XPS , PET foams, Cardboard, gray cardboard, KT board, Chevron board, honeycomb board, car sticker, light sheet, PP adhesive, inkjet cloth, flag cloth, various corrugated cardboard, PVC board, acrylic board, etc.

|

|

Safety device

|

Physical anti-collision mechanism + infrared induction anti-collision to ensure production safety

|

|

Cutting Thickness

|

≤50mm (Other thickness can be customized according to the material)

|

|

Cutting speed

|

≤1500mm/s(The actual speed depends on the material and cutting graphics)

|

|

Cutting precision

|

± 0.1mm

|

|

Repeat accuracy

|

≤0.05mm

|

|

Cutting circular diameter

|

≤3mm Diameter

|

|

Positioning way

|

Laser positioning also optional CCD camera positioning

|

|

Material fixed way

|

Vacuum adsorption

|

|

Transport interface

|

Ethernet front-end ports

|

|

Compatible software

|

AI software, AutoCAD, CorelDRAW, and all of the box type design software can output directly, without conversion, and with automatic optimization

|

|

Support File Format

|

DWG, AI, PLT, DXF

|

|

Operation panel

|

Multilingual languages LCD touch panel

|

|

Transmission system

|

High precision linear guide, meshing transmission gear and rack structure, Japanese Panasonic high performance servo drive motors+ precision reducer

|

|

Voltage / Hz

|

AC 220 v to 380 v + 10%, 50 - 60hz.

|

|

Power

|

11KW

|

|

Dimension(L*W*H)

|

3400*2270*1300mm

|

|

Weight

|

1400KG

|

|

Warranty

|

3 years

|

Colorful LCD touch operation panel supports multilingual languages, with more intuitive operation interface, which can directly input processing data, set processing speed and knife depth, support screen automatic protection, and protect processing data,feature-rich and user-friendly operation.

A variety of tool combinations, equipped with intelligent tools interchange system, can cut different materials to achieve different tasks, and multiple tool heads can work individually or in concert. Powerful function, fast running speed, high

processing accuracy, truly multi-purpose machine.

processing accuracy, truly multi-purpose machine.

Our machine frame/bed is characterized by high weight, strong load-bearing capacity and good stability, and the use of imported

gantry machining centers ensures the accuracy and stability of the oscillating knife cutting machine at high speed. We guarantee that the machine will not be deformed for 10 years.

gantry machining centers ensures the accuracy and stability of the oscillating knife cutting machine at high speed. We guarantee that the machine will not be deformed for 10 years.

The crossbeam adopts the extrusion process of aviation aluminum alloy die, which ensures the stability and high precision of machine operation at high speed, especially suitable for some industries that require high precision, such as sealing gaskets

.

Imported famous brand helical rack pinion , quenching and hardening treatment. High precision, strong load-bearing capacity, smooth running at high speed and less noise.

Taiwan PMI 20mm high precision linear guide, high positioning accuracy, high repeatability. Low friction resistance, high rigidity four-way load design, high speed and long time operation to maintain high precision

The worktable is a high precision and strength aluminum honeycomb vacuum absorption worktable with 40mm thickness. Cooperate with high power vacuum pump to fix the material.

4mm felt with built-in fiber tensile layer to protect the vacuum table and blades while the machine is working. Cutting-resistant, soft, won't scratch the product, non-slip, prevent the material from shifting during the cutting .

Use top quality Japan Panasonic servo motors and drivers(X-axis double servo motor driving + precision reducer drive). Strong power, long life, and high precision.

The ergonomic operating cabinet is beautifully designed and friendly to operate. Computer built-in genuine Windows 10 operating system, pre-installed feature-rich cutting software and nesting software, eliminating the need for customers to install software and set up parameters, saving customers' time.

Safety protection device. Highly sensitive collision avoidance system and red light brake system. When the machine is cutting at high speed, it can effectively protect safety of the operator.

It has an automatic feeding conveyor for rolls cutting. After cutting the material on the table. The feeding table automatically rolls forward to pull the material behind the table. and keep cutting. No need to manually pull the material forward. The cutting process also does not need to be interrupted, and with automatic deskew function.

Tips

With the continuous development of CNC technology, more and more customers choose Deveup intelligent cutting machine instead of workers. Deveup CNC oscillating digital knife cutter is widely used in the cutting and milling of EVA foam boards. It adopts advanced oscillating knife cutting technology with various cutting tools to meet different materails cutting. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

Advantages to using the Deveup cnc Oscillator Knife Cutter to cut foam:

1. More smart; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; Deveup EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials - round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; Deveup EVA foam cutting machine adopts Japanese Panasonic servo motors with cutting speed of up to max 1500mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CUTTING TOOL

Hot Searches