- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5.5Kw-22Kw

-

Weight:

-

800

-

Dimension(L*W*H):

-

1570*1450*1830

-

Operation:

-

Continuous

-

Discharge:

-

Automatic

-

Application:

-

Auto discharge disc centrifuge degummi

-

Material:

-

Stainless Steel

-

Capacity:

-

1-2T

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

FUYI

-

Voltage:

-

220, 380, 440, 460V....

-

Power:

-

5.5Kw-22Kw

-

Weight:

-

800

-

Dimension(L*W*H):

-

1570*1450*1830

-

Operation:

-

Continuous

-

Discharge:

-

Automatic

-

Application:

-

Auto discharge disc centrifuge degummi

-

Material:

-

Stainless Steel

-

Capacity:

-

1-2T

Products Description

FUYI Food Brand disc stack centrifuge

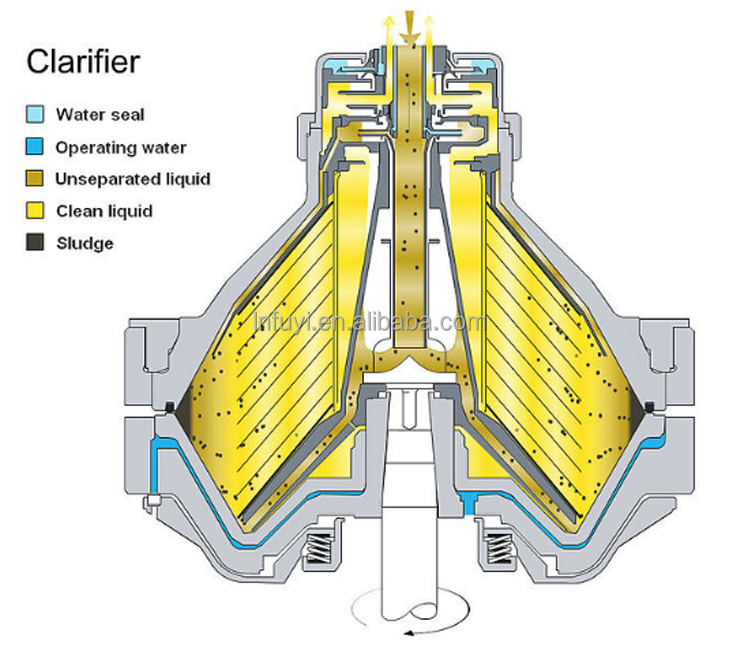

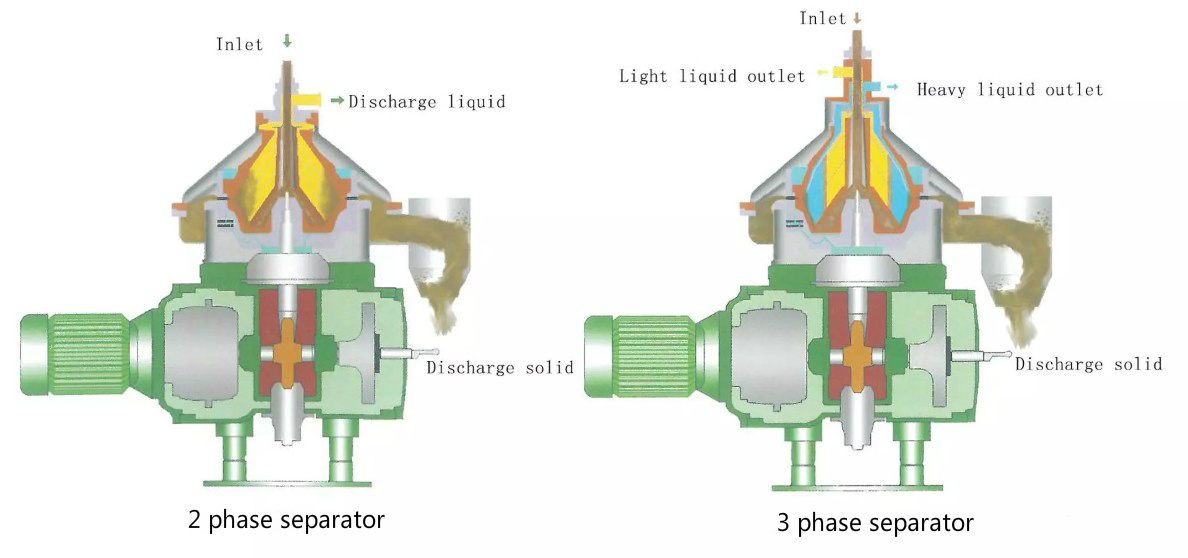

disc stack centrifuge is a kind of mechanical equipment for continuous separation of two kinds of liquid or solid-liquid suspensions with density difference by centrifugal sedimentation principle. It has the advantages such as high speed, smooth operation, closed import and export system, low noise and good separation effect. All the parts of the separator contacted with the materials are made of stainless steel, which meets the requirements of food hygiene.

The separator is mainly composed of import and export device, drum, vertical shaft, transverse shaft, fuselage, speed measuring device, brake device and motor. The centripetal pump structure is adopted for discharging material, after separation, the material is discharged by the centripetal pump, the output pressure is high (0-0.5 MPa), which can be directly transported to downstream equipment. Its drum has been accurately checked for dynamic balance, centrifugal friction clutch and large helical gear pair are used to transmit power in power transmission. The separator has the advantages of stable growth, avoiding overload, small vibration, safety and reliability, simple operation and convenient use. The bearings used in the separator all adopt Swedish SKF brand to ensure the operation accuracy of the equipment. If the separator is equipped with PLC electronic control system, the program operation can be realized..

The separator is mainly composed of import and export device, drum, vertical shaft, transverse shaft, fuselage, speed measuring device, brake device and motor. The centripetal pump structure is adopted for discharging material, after separation, the material is discharged by the centripetal pump, the output pressure is high (0-0.5 MPa), which can be directly transported to downstream equipment. Its drum has been accurately checked for dynamic balance, centrifugal friction clutch and large helical gear pair are used to transmit power in power transmission. The separator has the advantages of stable growth, avoiding overload, small vibration, safety and reliability, simple operation and convenient use. The bearings used in the separator all adopt Swedish SKF brand to ensure the operation accuracy of the equipment. If the separator is equipped with PLC electronic control system, the program operation can be realized..

Features:

1.Machine starts the friction to start off, about six to ten minutes. the machine runs smoothly, low noise and vibration, the installation path is very easy to operate.

2.The Stainless steel cover use SUS304.

3.The base use casting steel, coating does the same way as ship bottom.

4.Independent electric control cabinet can be remote controlled.

5.Safety protection: Rotating speed detection, over-vibrating protection, cover opening protection, motor overload & overheat protection, scraper's mechanical-electrical control

Benefits :

* High reliability drive train system.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids

* Super partial discharge(option) minimizes liquid loss and maximizes thickening of solid

* Full automation possible with PLC automatic control panel.

Scope of supply :

* One set separator

* One set PLC control box

* One set tools

* Electromagnetic flow-meter

* Sight glass

* High reliability drive train system.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids

* Super partial discharge(option) minimizes liquid loss and maximizes thickening of solid

* Full automation possible with PLC automatic control panel.

Scope of supply :

* One set separator

* One set PLC control box

* One set tools

* Electromagnetic flow-meter

* Sight glass

Technical Paramers

|

Model

|

DHC230

|

DHC230

|

DHC300

|

DHC360

|

DHC470

|

||||

|

Discharge time and Interval

|

Discharge time can be adjusted from 0.1-0.9 second,and discharge time interval can be adjusted from 1-240 minutes according to the raw meterial.

|

75

|

105

|

125

|

150

|

||||

|

Rotation speed rpm

|

7500-10000

|

7500

|

7300

|

7070

|

6600

|

||||

|

Water capacity L/H

|

500

|

500-1500

|

500-2000

|

500-3000

|

500-5000

|

||||

|

Motor power KW

|

1.5

|

4

|

4

|

7.5

|

15/18

|

||||

|

Weight kg

|

180

|

450

|

580

|

1280

|

1720

|

||||

Customer factory

Company

1,Liaoning FUYI Machinery Co.,Ltd

was established in June 2011 formerly known as Liaoning Sunny Pharmaceutical Machinery Co.,Ltd .Specially manufacturing centrifuge over 35 years

.

2,FUYI is specializing in the production and design of Disc centrifuge ,Tubular centrifuge ,Decanter centrifuge separator which are widely used in the Food and Dairy , Pharmaceutical and Medicine, Beverage,Plant Oil,Animal oil production.

3,FUYI Separator provide solution to all technological problems of liquid and solid with more than 3

0 years experience

in the centrifugal separation market. For better separation result , every series products is designed and manufactured based on the different liquid materials thus customer can achieve perfect separation performance.

4, FUYI separator promise to provide the most professional technology and advanced quality product for global customers.

5,Our company stocks many kinds of trial machine for customer taking materials to test and examine .We can offer our customers free separation test,

We made the Standard, we beyond it.

Welcome you come to FUYI for visiting and guiding.

Factory Size: 33000 square meters

Year Established: 2011

Total Revenue : US$1 Million - US$2.5 Million

Main Markets: Central America, Mid East, Oceania, Africa, South America

Year Established: 2011

Total Revenue : US$1 Million - US$2.5 Million

Main Markets: Central America, Mid East, Oceania, Africa, South America

Related products

FAQ

Q1: Where is your factory? How can I visit there?

A1: Our factory location is Liaoyang City , Liaoning Province, China.If want to visit our company , you can fly to Shenyang Taoxian Airport .

Q4: What's payment you accept?

A4: T/T, Western Union, L/C, Ali Pay, etc

A1: Our factory location is Liaoyang City , Liaoning Province, China.If want to visit our company , you can fly to Shenyang Taoxian Airport .

Q2: Do you have technicians for installation?

A2: We are responsible for the installation in your country, you can also arrange your staffs to our factory to learn how to operate the machines, after purchased ,we offer English manual book and operation videos.

Q3: What's your advantages compared to your competitors?

A3: Quality and experience, as evidenced by 40 patents and over 35 years of experience.

A2: We are responsible for the installation in your country, you can also arrange your staffs to our factory to learn how to operate the machines, after purchased ,we offer English manual book and operation videos.

Q3: What's your advantages compared to your competitors?

A3: Quality and experience, as evidenced by 40 patents and over 35 years of experience.

Q4: What's payment you accept?

A4: T/T, Western Union, L/C, Ali Pay, etc

Hot Searches