- Product Details

- {{item.text}}

Quick Details

-

Length:

-

49cm

-

Usage:

-

camping

-

Hardness:

-

standard

-

Al (Min):

-

84.35%

-

Wall Thickness:

-

0.72mm

-

Model Number:

-

ASTM B210 6082 T6

-

Brand Name:

-

TORICH

-

Product name:

-

Aluminium Alloy Tube

-

Type:

-

OEM Aluminum Extrusions Profiles

-

Material:

-

Alloy 6063/6061/6005/6060 T5/6082 T6

-

Application:

-

Construction

-

Keyword:

-

Alumimum Pipes

-

Surface:

-

Bright

-

Standard:

-

ASTM B210

-

Certification:

-

ISO9001:2008

-

MOQ:

-

1 Ton

Quick Details

-

Grade:

-

6000 Series

-

Tolerance:

-

±1%

-

Place of Origin:

-

Zhejiang, China

-

Length:

-

49cm

-

Usage:

-

camping

-

Hardness:

-

standard

-

Al (Min):

-

84.35%

-

Wall Thickness:

-

0.72mm

-

Model Number:

-

ASTM B210 6082 T6

-

Brand Name:

-

TORICH

-

Product name:

-

Aluminium Alloy Tube

-

Type:

-

OEM Aluminum Extrusions Profiles

-

Material:

-

Alloy 6063/6061/6005/6060 T5/6082 T6

-

Application:

-

Construction

-

Keyword:

-

Alumimum Pipes

-

Surface:

-

Bright

-

Standard:

-

ASTM B210

-

Certification:

-

ISO9001:2008

-

MOQ:

-

1 Ton

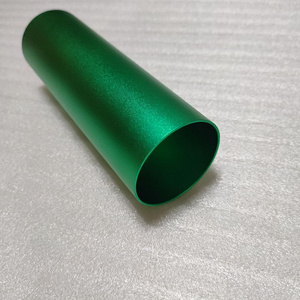

ASTM B210 6082 T6 Extruded Polished Anodized Hollow Aluminum Tube For Construction

Introduction

The ASTM B210 6082 T6 extruded polished anodized hollow aluminum tube is a versatile and widely used material in the construction industry. Known for its durability, lightweight properties, and excellent corrosion resistance, this aluminum tube is a top choice for a variety of construction applications. In this article, we will delve into the material, specifications, key features, chemical composition, mechanical properties, steel grade, applications, and possible alternative grades of ASTM B210 6082 T6 aluminum tubes for construction.

Material and Specification

- Material Type: ASTM B210 6082 T6 Extruded Polished Anodized Hollow Aluminum Tube

- Standard: ASTM B210

- Aluminum Alloy Grade: 6082 T6

- Surface Finish: Polished and Anodized

- Tube Type: Hollow

Key Features

- Corrosion Resistance: 6082 T6 aluminum alloy offers excellent resistance to corrosion, making it ideal for construction applications in various environments.

- High Strength: This alloy has a high strength-to-weight ratio, providing structural integrity without excessive weight.

- Lightweight: Aluminum is inherently lightweight, facilitating easy transportation and installation.

- Anodized Finish: The anodized finish not only enhances corrosion resistance but also provides an attractive appearance.

- Extruded Design: Extrusion ensures precise dimensions and consistency in the tube's shape.

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Silicon (Si) | 0.7 - 1.3 |

| Iron (Fe) | 0.0 - 0.5 |

| Copper (Cu) | 0.0 - 0.1 |

| Manganese (Mn) | 0.4 - 1.0 |

| Magnesium (Mg) | 0.6 - 1.2 |

| Chromium (Cr) | 0.25 - 0.35 |

| Zinc (Zn) | 0.0 - 0.2 |

| Titanium (Ti) | 0.0 - 0.1 |

| Other Elements | <0.05 |

| Aluminum (Al) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 270 - 350 |

| Yield Strength (MPa) | 240 - 310 |

| Elongation (% in 50mm) | 6 - 12 |

| Modulus of Elasticity (GPa) | 70 - 80 |

| Hardness (Brinell, HB) | 95 - 110 |

Steel Grade

ASTM B210 6082 T6 aluminum tubes are not classified by a steel grade, as they are made from aluminum alloy rather than steel.

Application

The ASTM B210 6082 T6 extruded polished anodized hollow aluminum tube finds widespread use in the construction industry for various applications, including:

-

Structural Frameworks: These tubes are employed in building frameworks, providing essential support while keeping structures lightweight.

-

Architectural Elements: Aluminum tubes are used for architectural features like handrails, balustrades, and decorative elements due to their aesthetic appeal and corrosion resistance.

-

Piping Systems: They are used in plumbing and fluid transportation systems, thanks to their corrosion resistance and easy installation.

-

Scaffolding: Aluminum tubes are commonly used for scaffolding, as their lightweight nature makes assembly and disassembly more manageable.

-

Transportation: In the construction of vehicles and trailers, aluminum tubes contribute to reducing overall weight and improving fuel efficiency.

Possible Alternative Grades

While ASTM B210 6082 T6 aluminum tubes are well-suited for many construction applications, there are alternative aluminum grades available that may be considered based on specific project requirements. Some alternative aluminum grades include:

-

ASTM B221 6061 T6: Known for its high weldability and versatility, 6061 T6 aluminum is often chosen when welds or additional machining are required.

-

ASTM B483 7075 T6: Offering exceptional strength and hardness, 7075 T6 aluminum is suitable for applications where maximum strength is necessary, such as aerospace components.

-

ASTM B211 2011 T3: This grade is valued for its excellent machining characteristics, making it a preferred choice for parts that require intricate machining.