* 3tons passive decoiler

* Coil inner Diameter: ¢460-520mm

* Max out diameter of the coil: ¢800mm

* Max Coil Width:500mm

- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Rolling speed:

-

5-10m/min

-

Rolling thickness:

-

0.3-0.8mm

-

Raw material:

-

Galvanized steel sheet

-

Roller stations:

-

About 18 stations

-

Roller material:

-

45#forge steel, coated with chrome

-

Transmission:

-

By chain 1 inch

-

Tolerance:

-

6m+-0.5mm

-

Control system:

-

PLC

-

Voltage:

-

220V, 60HZ,3 phase Also can satisfy customer's require

Quick Details

-

Weight (KG):

-

8000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Rolling speed:

-

5-10m/min

-

Rolling thickness:

-

0.3-0.8mm

-

Raw material:

-

Galvanized steel sheet

-

Roller stations:

-

About 18 stations

-

Roller material:

-

45#forge steel, coated with chrome

-

Transmission:

-

By chain 1 inch

-

Tolerance:

-

6m+-0.5mm

-

Control system:

-

PLC

-

Voltage:

-

220V, 60HZ,3 phase Also can satisfy customer's require

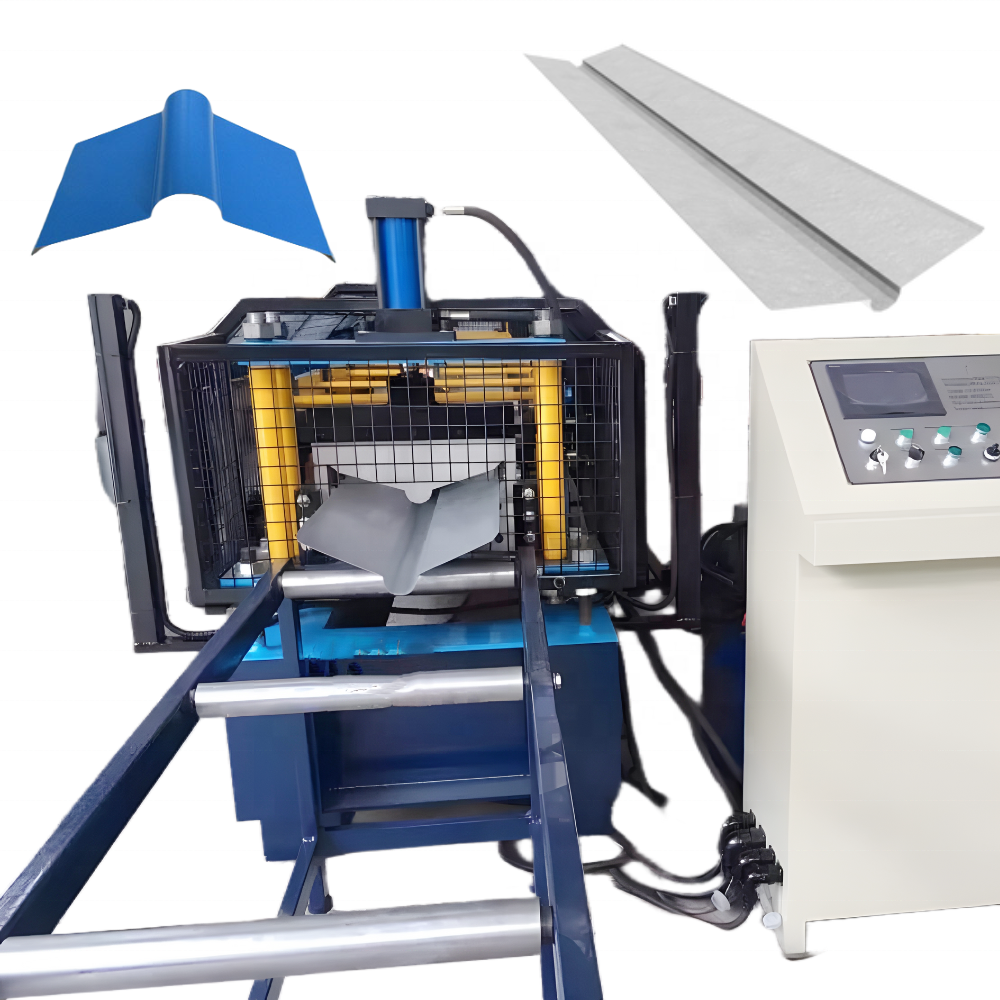

Product Description

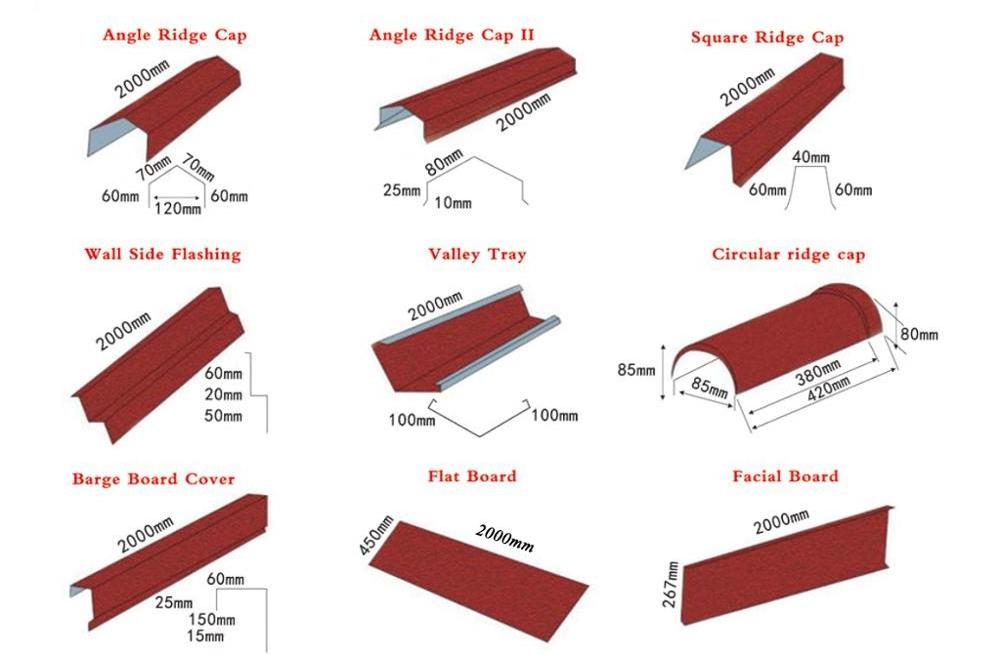

The ridges Capping were designed to cover the parting of roofs with two slopes, and have the purpose of unifying the roof. so the ridge capping is manufactured in the same material as the roof panels. This means that the buildings retain their aesthetics and design.

As usual, the ridge capping is about 0.3 mm-0.8 mm thickness. This ridge capping with perforation is hottest sale in South America. The ridge capping can be together with the IBR 686 , R 72, R 101, PV 4, PV 6, 5 V , Corrugated, TR 4 roof panels. If you are interested in it, please contact us. Technical Data:

As usual, the ridge capping is about 0.3 mm-0.8 mm thickness. This ridge capping with perforation is hottest sale in South America. The ridge capping can be together with the IBR 686 , R 72, R 101, PV 4, PV 6, 5 V , Corrugated, TR 4 roof panels. If you are interested in it, please contact us. Technical Data:

|

|

Items |

Specifications |

|

Material of coil

|

Material Thickness

|

0.3—0.8mm

|

|

|

Un Coiler

|

3 tons manual

|

|

Forming system

|

Rolling Speed

|

5-10m/min

|

|

|

Roller Stations

|

18 stations

|

|

|

Roller material

|

45# steel, coated with chrome

|

|

|

Maim Motor Power

|

7.5kw

|

|

|

Hydraulic cutting Power

|

7.5kw

|

|

Cutting system

|

Material Of Cutting

|

CR12 with quench treatment

|

|

|

Hardness

|

HRC58-62

|

|

|

Tolerance

|

+-1.5mm

|

|

Electrical control system

|

Electric Source

|

220V, 60HZ,3 phase

Also can satisfy customer’s require |

|

|

Control System

|

PLC with touch screen

|

|

|

Way Of Drive

|

1.2 inch single chain

|

|

Packing information

|

Color of the machine

|

blue

|

Machine List:

|

3 ton passive de-coiler

|

1 set

|

|

Hydraulic Punching device

|

1 set

|

|

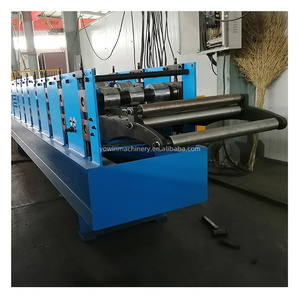

Main roll forming machine

|

1 set

|

|

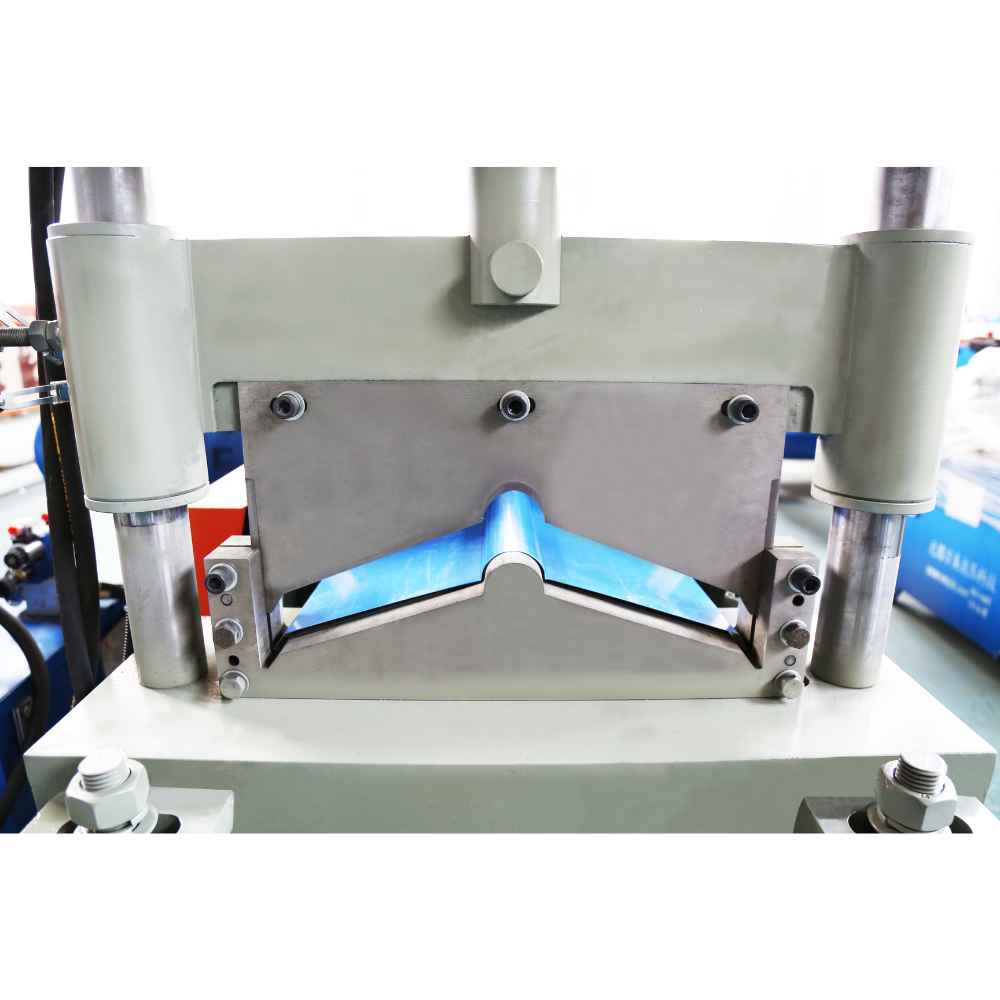

Punching press mould

|

1 set

|

|

Control box

|

1 unit

|

|

Hydraulic station

|

1 unit

|

|

Out table

|

1 unit

|

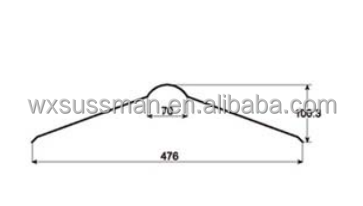

Profile Drawing:

Product Display

3 Tons Passive Decoiler

Hydraulic Cutting

* Cutting after forming: Cut the sheet after roll forming to required length

* Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will

automatically start.

* Material of blade: CR12mov with heat treatment

* Length measuring: Automatic length measuring

* Tolerance of length: 10m+/- 2mm

* Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will

automatically start.

* Material of blade: CR12mov with heat treatment

* Length measuring: Automatic length measuring

* Tolerance of length: 10m+/- 2mm

Output Tables

It adopts welded steel and supported roller to

transmit the products.

Size:2 meters length 2 units

transmit the products.

Size:2 meters length 2 units

Control System

* Power supplier: 220V, 60 Hz, 3Phase (adjusted with therequestment)

* length & quantity measurement automatically;

* length & quantity controlled by PLC

* Length inaccuracy can be amended easily.

* Control panel: Button-type switch and touch screen

* Unit of length: millimeter (switched on the control panel)

* length & quantity measurement automatically;

* length & quantity controlled by PLC

* Length inaccuracy can be amended easily.

* Control panel: Button-type switch and touch screen

* Unit of length: millimeter (switched on the control panel)

Application

Hot Searches