With Visible Window.

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CapsulCN

-

Voltage:

-

220V50HZ/110V60HZ

-

Dimension(L*W*H):

-

1600*1600*1600mm

-

Weight (KG):

-

620

-

Power (kW):

-

1.2

-

Model:

-

PBDS-12B

-

Product name:

-

Automatic Capsule Counting Machine

-

Application:

-

Tablet Capsule Pill Candy Counting

-

Function:

-

Bottle Filling

-

Keyword:

-

Capsule Counting Bottling Machine

-

Feature:

-

Counting Capsule Tablet Candy Gummy

-

Material:

-

Staninless Steel

-

Operation:

-

Automatic Operation

-

Useage:

-

Count Bottling Capsule Tablet Pill

-

Advantage:

-

High Speed . High Grade

Quick Details

-

Capacity (bottle/min):

-

30 - 55 bottle/min

-

Bottle Capacity (pcs/bottle):

-

1 - 99999 pcs/bottle

-

Capacity (pcs/h):

-

9999 pcs/h

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CapsulCN

-

Voltage:

-

220V50HZ/110V60HZ

-

Dimension(L*W*H):

-

1600*1600*1600mm

-

Weight (KG):

-

620

-

Power (kW):

-

1.2

-

Model:

-

PBDS-12B

-

Product name:

-

Automatic Capsule Counting Machine

-

Application:

-

Tablet Capsule Pill Candy Counting

-

Function:

-

Bottle Filling

-

Keyword:

-

Capsule Counting Bottling Machine

-

Feature:

-

Counting Capsule Tablet Candy Gummy

-

Material:

-

Staninless Steel

-

Operation:

-

Automatic Operation

-

Useage:

-

Count Bottling Capsule Tablet Pill

-

Advantage:

-

High Speed . High Grade

Product Description

|

Model

|

PBDS-8

|

PBDS-12

|

PBDS-16

|

|||

|

Capacity

|

Max.50 bottles/min

|

Max.55 bottles /min

|

60-100 bottles/min

|

|||

|

(

Related to material variety, size, bottle specifications, and bottled volume

)

Please contact us for details

.

|

|

|

|

|||

PBDS-12 Electronic Counting Machine ( Customized double feeder )

PBDS-12 Tablet Counter is a solid dose product counting machine that features cutting-edge technologies such as multi-channel vibratory feeding, computer control, dynamic scan counting, automatic bottle feeding, and photoelectric control.

With advanced optomechatronic technologies ,

GMP compliant, this counter is designed with an HMI and an intelligent safety system including detection, error messaging, fault alarm, and automatic shutdown. Can be used independently, and can also form a linked production line with other supporting equipment such as

bottle unscrambler

,

paper stopper

,

capping machine

,

sealing

and

labeling machine

.

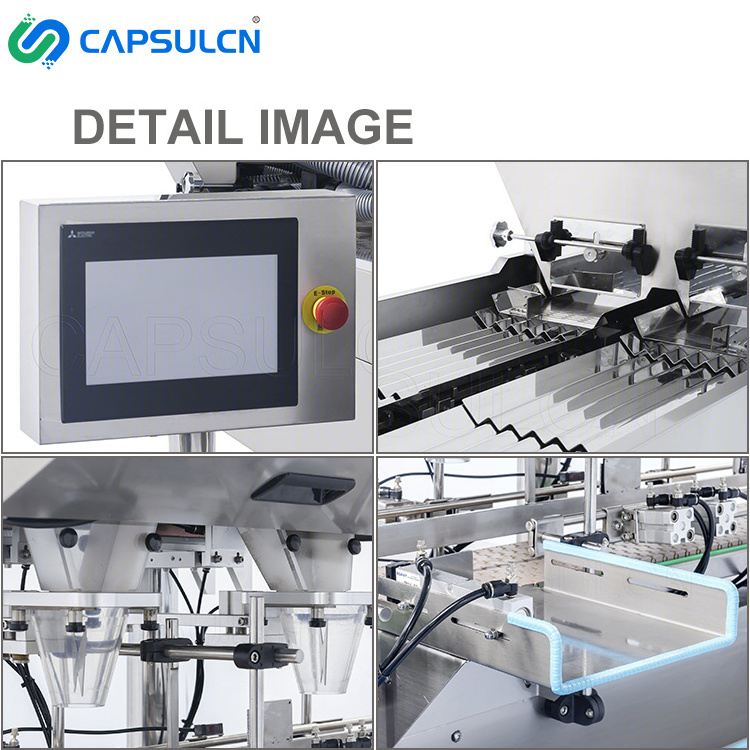

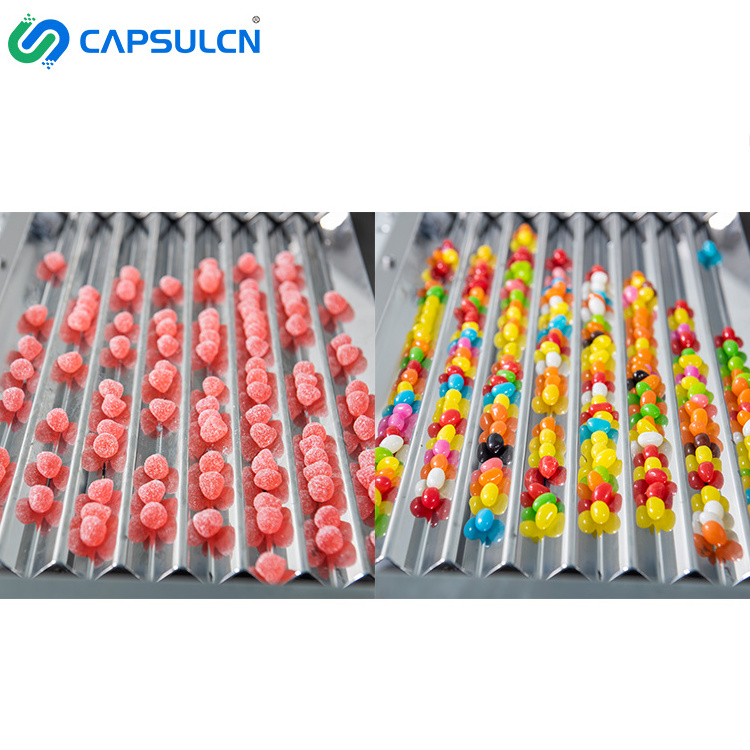

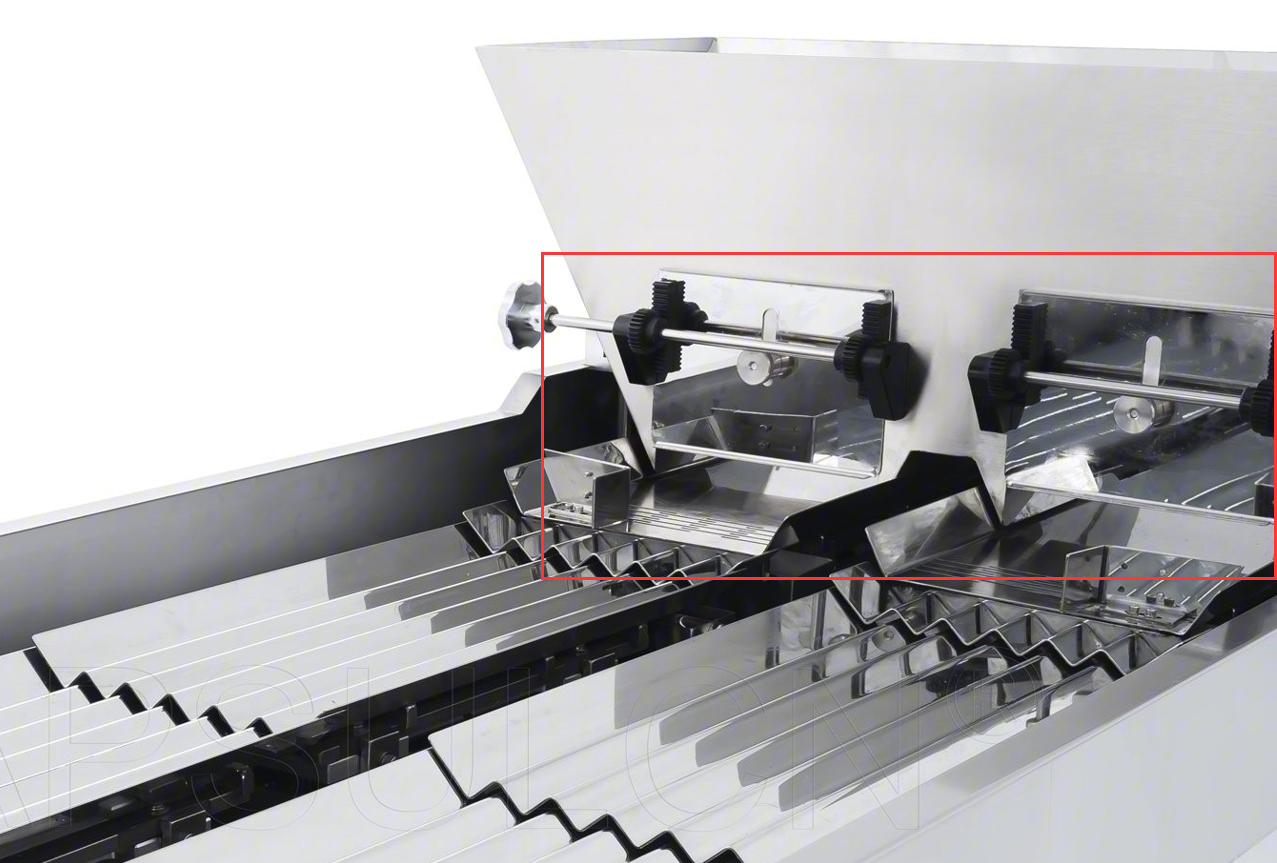

Details Images

Hopper

Channel Blocker for Different Counting Quantities.

Each individual channel is equipped with sensors to count.

Wider Channel

3-stage vibration units separate and transmit

materials

to the detection unit.

Mitsubishi or Siemens HMI.

Memory capacity for up to 15 jobs, 100 jobs for option.

Counting Accuracy: 99.99%

Module Sensor for easy dismantle.

Auto rejection system removes incorrectly-filled containers off the conveyor.

Side Holder for Tools or Rejected Bottles.

Supporting machines:C

ounting bottling production line

Why Choose Us

Pre-sale service

1.

Support product customization

, any requirements you need can be customized according to your requirements.

2. Sample test on our machine.

3. Provide business consulting and technical support, as well as a free professional packaging solution.

4. Make a machine layout for customers based on customers' factories.

After-sales service

1. Manual book.

2. Videos of installation, adjusting, setting, and maintenance, are available for you.

3. Online support, or face-to-face online communications, are available.

4.

The engineer overseas services

, are available. The tickets, visa, traffic, living, and eating, are for customers.

5. During the warranty year, without human-being broken, we will replace a new one for you.

Recommend Products

Hot Searches