- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Standard

-

Name:

-

wet cleaning machine

-

Application:

-

Automative, Marine, Reginery, Fleet vehicles

-

Model:

-

ATDB225 ATDB500 ATDB800

-

Usage:

-

Cleaning metal Surface

-

Function:

-

Graffiti removal, stripe Removal

-

Other name:

-

glass sand blasting machine

-

Media:

-

water and glass bead

-

Color:

-

Customers' Requirements

-

Abrasive:

-

glass bead

-

Air Consumption:

-

6 M3/min

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Qingdao Antai brand

-

Power:

-

Standard

-

Dimension(L*W*H):

-

Standard

-

Name:

-

wet cleaning machine

-

Application:

-

Automative, Marine, Reginery, Fleet vehicles

-

Model:

-

ATDB225 ATDB500 ATDB800

-

Usage:

-

Cleaning metal Surface

-

Function:

-

Graffiti removal, stripe Removal

-

Other name:

-

glass sand blasting machine

-

Media:

-

water and glass bead

-

Color:

-

Customers' Requirements

-

Abrasive:

-

glass bead

-

Air Consumption:

-

6 M3/min

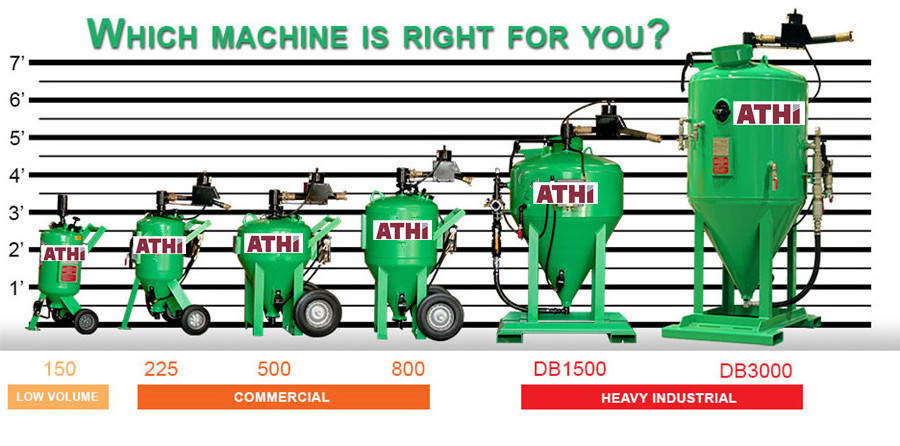

DB225 DB500 DB800

dustless sand blasting machine for sale

Product Application

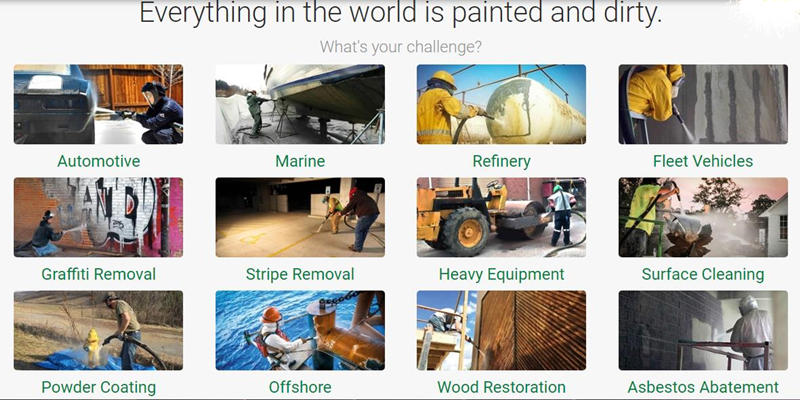

Our dustless sand blasting machines are mainly designed and integrated with the wide range of nozzles, wet blast attachments, internal pipe cleaning devices, dust free blasting heads, abrasive control device.

The dustless sand blasting machine is used for every filed in the world, such as, Automative, Marine, Reginery, Fleet vehicles, Graffiti removal, stripe Removal, Heavy equipment, Surface cleaning, Powder coating, Offshore, Wood restoration, Asbestos Abaement.

Dustless sand blasting recognizes the needs of the industry and our machines offer all the features that the professional use requires. All machines can be fitted with a well designed and proven single piece remote control dead man switch and silencer which significantly reduce labour cost, improve efficiency of abrasive, performance and safety.

The machines are constructed for a maximum 150 PSI working pressure. The pneumatic abrasive remote control valve can achieve operators to stop or start .

Technical parameter

(1). Blast tank

|

Technical Paramete |

ATDB150 |

ATDB225 |

ATDB500 |

ATDB800 |

ATDB1500 |

ATDB3000 |

|

Blasting mode |

air jet |

air jet |

air jet |

air jet |

air jet |

air jet |

|

Capacity |

0.028m³ 1cubic foot |

0.057m³ 2cubic foot |

0.14m³ 5cubic foot |

0.23m³ 8cubic foot |

0.42m³ 15cubic foot |

0.85m³ 30cubic foot |

|

blast time |

~15min |

~30min |

~60 min |

~90 min |

~2-3 hours |

~4-6 hours |

|

Compressor |

60+CFM |

185+CFM |

185+CFM |

185+CFM |

375+CFM |

375+CFM |

|

Size (H/W/D) |

1219/508/559mm 48”H*20”W*22”D |

1397/686/864mm 55”H*27”W*34”D |

1372/864/1016mm 54”H*34”W*40”D |

1600/864/1016mm 63”H*34”W*40”D |

1930/1219/1168mm 76”H*48”W*46”D |

2490/1219/1168mm 98”H*48”W*46”D |

|

Weight |

72 kg 158lbs |

120 kg 263lbs |

167 kg 368lbs |

194 kg 427lbs |

380 kg 838lbs |

544kg 1200lbs |

|

Operating Pressure |

30-150 PSI |

30-150 PSI |

30-150 PSI |

30-150 PSI |

30-150 PSI |

30-150 PS |

|

Blasting hose length |

15m |

15m |

15m |

15m |

30m |

30m |

|

Nozzle Dia |

Φ8/10/12mm |

Φ8/10/12mm |

Φ8/10/12mm |

Φ8/10/12mm |

Φ8/10/12mm |

Φ8/10/12mm |

(2). Requirement for air compressor

4-10 bar, 60-3755 CFM, 30-150 PSI, 0.2-1.0 Mpa

(3). Includes

A. Blast hose(Inner diameter is ID25OD38mm or ID32OD48mm)

B. Deadman activator valve

C. Tungsten carbide nozzle(diameter is 8/10/12mm)

D. Fill funnel

E. Lifetime warranty on blast pot

(4). Consumables

|

Type |

Water |

Abrasive |

Rust Inhibitor |

|

DB150 |

5gal (19L) |

50lbs (22.68kg) |

7oz (207g) |

|

DB225 |

10gal (38L) |

100lbs (45.36kg) |

14oz (414g) |

|

DB500 |

20gal (76L) |

200lbs (90.72kg) |

28oz (828g) |

|

DB800 |

30gal (114L) |

300lbs (136.08kg) |

42oz (1242g) |

|

DB1500 |

75gal (284L) |

750lbs (340.2kg) |

105oz (3105g) |

|

DB3000 |

150gal (568L) |

1500lbs (680.4kg) |

1.5gal (5.68L) |

Main Features

1.High quality surface appearance

2.High productivity efficiency

3.Low cost

4.Environmental friendly

5.Lower abrasive consumption

6.Safe, no sparking

7.Less contamination

8.Not necessary to stop nearby jobs.

9.Removes scale for a paint ready surface.

10. Requires only a parking space

11. Does not warp metal

12. Leaves a primer-ready surface

13. Easy to clean up

14. Prevents rust for 72 hours

The Dustless sand blasting machine painting process

The Dustless sand blasting machine cleaning surface efficiency

The Dustless sand blasting delivery process

The dustless sand blasting machine details pictures----ATDB150&DB225&DB500&DB800

Australia customers visited our factory, checked the dustless blaster