- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

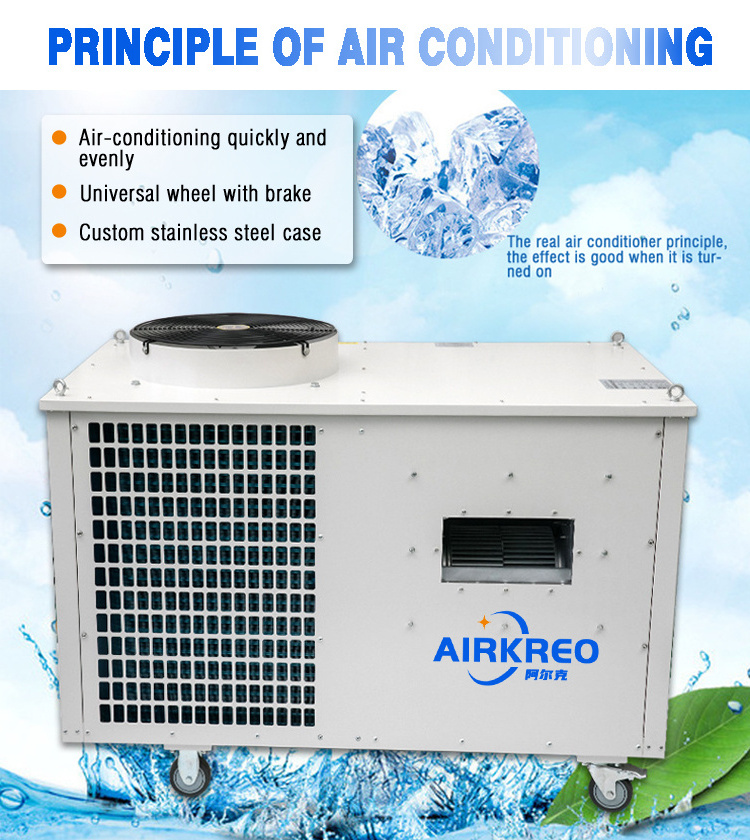

Brand Name:

-

AIRKREO

-

Dimension(L*W*H):

-

1400mm*810mm*940mm

-

Core Components:

-

compressor

-

Weight (KG):

-

200 KG

-

Cooling capacity:

-

1800W/61000BTU

-

Refrigerant:

-

R22/R410A

-

Noise:

-

65-70dB

-

Compressor:

-

Fully enclosed turbine

-

Color:

-

customizable

-

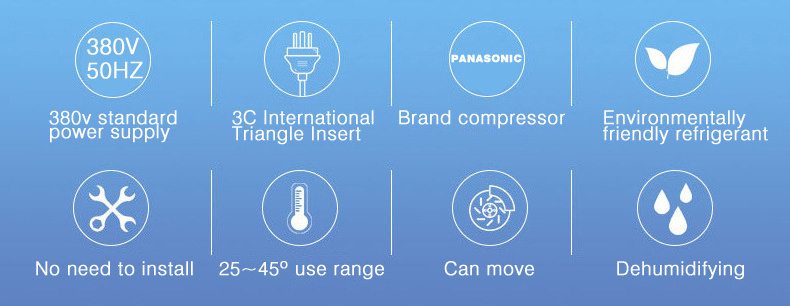

Power supply:

-

380V AC/50HZ

-

Rated current:

-

12.6A

-

Maximum power consumption:

-

7800W

-

Operating pressure:

-

2.2MPa

-

Net weight:

-

200KG

Quick Details

-

Type:

-

AIR COOLER

-

Mounting:

-

Floor Standing

-

Airflow:

-

4000m³/h

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

AIRKREO

-

Dimension(L*W*H):

-

1400mm*810mm*940mm

-

Core Components:

-

compressor

-

Weight (KG):

-

200 KG

-

Cooling capacity:

-

1800W/61000BTU

-

Refrigerant:

-

R22/R410A

-

Noise:

-

65-70dB

-

Compressor:

-

Fully enclosed turbine

-

Color:

-

customizable

-

Power supply:

-

380V AC/50HZ

-

Rated current:

-

12.6A

-

Maximum power consumption:

-

7800W

-

Operating pressure:

-

2.2MPa

-

Net weight:

-

200KG

Products Description

Product Paramenters

|

1

|

Model

|

QD-180

|

|

2

|

Power supple

|

380V AC/50HZ

|

|

3

|

Cooling capacity

|

18000W/61000BTU

|

|

4

|

Air volume selection

|

Strong

|

|

5

|

Cold air discharge

|

4000m

3

/h(four-stage motor)

|

|

6

|

Warm air discharge

|

7000m

3

/h

|

|

7

|

Rated current

|

12.6A

|

|

8

|

Maximum current

|

15.8A

|

|

9

|

Power comsamption

|

5650W

|

|

10

|

Maximum power consumption

|

7800W

|

|

11

|

Compressor

|

Fully enclosed rotany

|

|

12

|

Condensate treatment method

|

Ecternal water pipe

|

|

13

|

Refrigerant

|

R22/R410A

|

|

14

|

Refrigerant jnjection

|

3800g

|

|

15

|

Exhaust pressure

|

1.8MPa

|

|

16

|

Suction pressure

|

0.69MPa

|

|

17

|

Operating pressure

|

2.2MPa

|

|

18

|

Use environment

|

18℃~45℃

|

|

19

|

Dimensions

|

1400mm*810mm*940mm

|

|

20

|

N.W(kg)

|

200

|

Case Show

Transport

Certifications

FAQ

Q1: Are you manufacturer or trading company?

A1 : We are manufacturing factory + trade integration with more than 15years production experience in this field and 5 years exporting experience.

Q2: Can I get samples?

A2 :Yes we can provide samples, client need pay the sample fees and express charge.

Q3: Is it possible to make our logo on the product?

A3 : OEM and ODM is available, including special design,color, logo, packing etc.

Q4: Can I get any discount?

A4 : The price is negotiable, we can offer you discount according to your order quantity.

Q5: What is the process of an order?

A5 : Making artwork and design drawing---making samples---samples test---mass production---finished product inspection---packing

Q6: What is your delivery period?

A6 : Generally around 10-25days. If we have inventory, we can arrange shipment within 3days.(Only need time to change the plug and do the pre-shipment test) Also, production lead time depends on specific items and quantity.

Q7: What about the warranty-after sales service?

A7: We offer 1 year warranty for our machines.We have after-sales department for 24hours consultation service.

A1 : We are manufacturing factory + trade integration with more than 15years production experience in this field and 5 years exporting experience.

Q2: Can I get samples?

A2 :Yes we can provide samples, client need pay the sample fees and express charge.

Q3: Is it possible to make our logo on the product?

A3 : OEM and ODM is available, including special design,color, logo, packing etc.

Q4: Can I get any discount?

A4 : The price is negotiable, we can offer you discount according to your order quantity.

Q5: What is the process of an order?

A5 : Making artwork and design drawing---making samples---samples test---mass production---finished product inspection---packing

Q6: What is your delivery period?

A6 : Generally around 10-25days. If we have inventory, we can arrange shipment within 3days.(Only need time to change the plug and do the pre-shipment test) Also, production lead time depends on specific items and quantity.

Q7: What about the warranty-after sales service?

A7: We offer 1 year warranty for our machines.We have after-sales department for 24hours consultation service.

ANALYSIS OF THREE MAIN REASONS WHY MOBILE AIR CONDITIONERS ARE NOT REFRIGERATING

1. The over-temperature maintenance of the refrigeration compressor causes the switching power supply to be disconnected. When the industrial air conditioner is in use, the operating voltage is too low or too high, or the operating temperature is too high, which will cause the refrigeration compressor of the industrial air conditioner to over-temperature load, in order to maintain the refrigeration compressor, the thermal overcurrent protector will disconnect the refrigeration Compressor switch power supply. At this time, when the over-temperature and over-pressure protection device of the industrial air-conditioner is operating, the industrial air-conditioner is not easy to refrigerate and only blows air. If the thermal overcurrent protector is often disconnected, remember that it cannot be started frequently, and the cause should be found and removed before applying the industrial air conditioner. It is the key reason why industrial air-conditioners skip electricity and do not refrigerate.

2. Common failure caused by clogged filter. Like traditional central air conditioners, industrial air conditioners have filters

at the air inlets. If the filter screen contains dust, stains, etc., it will harm the air intake and exhaust flow of the air

conditioner, and it is very easy to cause the heat exchanger to frost and cause common failures of the equipment. The filter must be drawn out, and the dust on the filter must be removed with a vacuum cleaner, and then cleaned with tap water, and then applied after it is completely dry. It is also important to note here that when cleaning the filter, do not use paint thinner, volatile oil, drugs, etc., as this will damage the filter and the surface of the industrial air conditioner.

3. Application of non-standard switching power supply extension cords leads to common failures. Industrial air conditioners can use switching power supply extension cords, but there are certain regulations for switching power supply extension cords. If the extension cord is too long or too thin, the operating voltage will drop and the equipment will not be able to operate normally, causing common failures of the air conditioner.

2. Common failure caused by clogged filter. Like traditional central air conditioners, industrial air conditioners have filters

at the air inlets. If the filter screen contains dust, stains, etc., it will harm the air intake and exhaust flow of the air

conditioner, and it is very easy to cause the heat exchanger to frost and cause common failures of the equipment. The filter must be drawn out, and the dust on the filter must be removed with a vacuum cleaner, and then cleaned with tap water, and then applied after it is completely dry. It is also important to note here that when cleaning the filter, do not use paint thinner, volatile oil, drugs, etc., as this will damage the filter and the surface of the industrial air conditioner.

3. Application of non-standard switching power supply extension cords leads to common failures. Industrial air conditioners can use switching power supply extension cords, but there are certain regulations for switching power supply extension cords. If the extension cord is too long or too thin, the operating voltage will drop and the equipment will not be able to operate normally, causing common failures of the air conditioner.

Hot Searches