- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MOOGE

-

Application:

-

PET recycling

-

Production Capacity (kg/h):

-

300 - 5000

-

Voltage:

-

380V 50HZ 3P

-

Dimension(L*W*H):

-

135 X 8 X 6.5M

-

Power (kW):

-

185-1000 KW

-

Weight (T):

-

40

-

Water consumption:

-

4-50 cubic meter

-

Motor brand:

-

Siemens

-

Inverter Brand:

-

Delta or ABB

-

Bearing Brand:

-

NSK or SKF

-

Pet recycling flakes moisture:

-

<1%

-

Hot Washing Tank Heating:

-

by Electric or steam

-

Recycling Line Manual:

-

5-20 Person

-

Recycling PET Flakes Size:

-

12-16mm

-

Washing Machine Material:

-

Stainless steel

-

Recycling Machine Motor:

-

WEG

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

5000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MOOGE

-

Application:

-

PET recycling

-

Production Capacity (kg/h):

-

300 - 5000

-

Voltage:

-

380V 50HZ 3P

-

Dimension(L*W*H):

-

135 X 8 X 6.5M

-

Power (kW):

-

185-1000 KW

-

Weight (T):

-

40

-

Water consumption:

-

4-50 cubic meter

-

Motor brand:

-

Siemens

-

Inverter Brand:

-

Delta or ABB

-

Bearing Brand:

-

NSK or SKF

-

Pet recycling flakes moisture:

-

<1%

-

Hot Washing Tank Heating:

-

by Electric or steam

-

Recycling Line Manual:

-

5-20 Person

-

Recycling PET Flakes Size:

-

12-16mm

-

Washing Machine Material:

-

Stainless steel

-

Recycling Machine Motor:

-

WEG

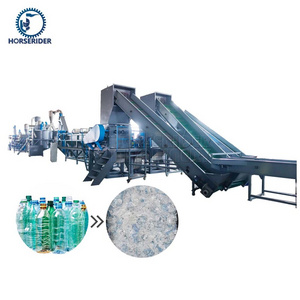

Products Description

More than 15 years of technology and process experience precipitation, MOOGETECH has a variety of different solutions for recycling waste pet plastic

Recycling Washing Plastic Material Include:

Water bottle, Sprite bottle, cola bottle, juice bottle, pet sheet, pet packing container, pet strap, pet film and so on.

According to final usage of pet flakes, We supply 3 model grade pet bottle flakes :

- Bottle to bottle grade, Food Standard

- Yarn/filament grade

- Conventional grade

New R-Pet washing recycling bottle flakes application:

R-PET flakes can be make new food bottle , 2-d or 3-d pet fiber,filament yarn,pet strap,pet sheet ,pet film etc.

Suitable Products

Product Specification

|

Recycling Model

|

Capacity

|

Installed Power

|

Water Supply

|

Area Required

|

|

MT-500

|

500 kg/hr

|

190 KW

|

4-5 m3/hr

|

60*5*5 m

|

|

MT-1000

|

1000 kg/hr

|

260 KW

|

6-8 m3/hr

|

80*8*5 m

|

|

MT-2000

|

2000 kg/hr

|

400 KW

|

10-15 m3/hr

|

80*8*5 m

|

|

MT-3000

|

3000 kg/hr

|

600 KW

|

20-30 m3/hr

|

100*8*10 m

|

|

MT-4000

|

4000 kg/hr

|

800 KW

|

30-40 m3/hr

|

135*10*10 m

|

|

MT-5000

|

5000 kg/hr

|

1000 KW

|

40-50 m3/hr

|

135*10*10 m

|

|

Recycling Line Energy Consumption

|

|

|

|

Content

|

Average energy consumption per ton of bottle

|

|

|

Electricity

|

70-90KW

|

|

|

Water

|

1-1.5T/hr

|

|

|

Compressed air

|

0.5-1m3

|

|

|

Steam (optional)

|

250-400KG

|

|

|

Detergent (optional)

|

4-8KG

|

|

|

Bottle Flakes Quality After Washing Recycling

|

|

|

|

Technical Parameter

|

Specifications

|

|

|

Flakes size

|

10-12 mm

|

|

|

Moisture Content

|

<1%

|

|

|

PVC Content

|

Less than 50 ppm

|

|

|

PH

|

7.5 +/- 0.5

|

|

|

Intrinsic Viscosity

|

> 0.70

|

|

|

Non-PET

|

Less than 50 ppm

|

|

|

Color PET

|

Less than 50 ppm

|

|

|

Bulk density

|

250-400 kg/m³

|

|

|

Suitable to be used for

|

Polyester/ PET strapping/ Polyester Fiber/ PSF/ PET Sheet

|

|

Product Details

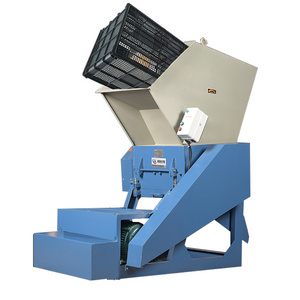

Bale Opener Machine

--With 4 roller cylinder to feeding the bottles equal.

--

Machine chamber made by solid strong steel.

--

Motor speed adjust by inverter.

--Machine fixed with support over the conveyor.

Bottle Trommel Separator Machine

--Loose pet bottle and remove caps, sand, soil and feeding the bottles out constantly before next washing recycling

--

Motor speed adjust by inverter.

--

The track and gear made by one unit steel with forging steel strong and heating treatment.

--With high platform with dirty collecting chute, put the jumbo bags under the Trommel

Label Remover Machine

--Dry type (We also supply water model label remover machine)

--

Used to remove the labels from the bottle and separate label out from bottles.

--

Label remove effective > 98% ,more label will be remover it before crushing washing recycling

--

Blade made by alloyed steel for long time use.

--Blade is fixed by screw on the rotor easy to adjustable and changeable, maintenance.

Plastic Crusher Machine

--With water inlet on machine top do wet crushing.

pre washing dirty bottle flakes in recycling line

--The rotary and fixed blades fixed by screw inside the crusher are more wider and durable.

--Crusher hopper is open by screw motor which save manpower.

--Bearing house is installed outside of the crusher chamber so no dirty goes inside.

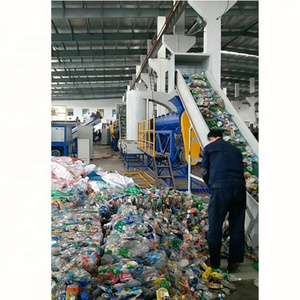

Floating Washing Tank

--With the top rollers automatic take out the caps/rings and other impurities, flakes sinking down and take out by bottom screw.

--

With the rollers working will use less water to take out the caps/rings.

--The machine made by SUS 304.

--Using More Washing Tank in recycling line , more clean bottle flakes

Hot Washing Tank

--With hot water washing to remove oil/glue and other dirt from the flakes.

--

Heating method: by Steam or Electricity.

--The tank made with insulation layer to save energy.

-- Double Layer Barrel Making, c

ontinue

heat preservation 24 hours , save engry for recycling line and cost for customer

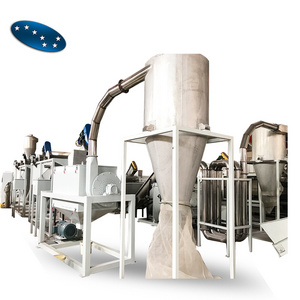

Horizontal Spin Dewatering Dryer

--Friction washing the material and its running with high speed can remove the dirty, dust, sand out with the dirty water.

--

With the roller bearing and fixed outside of rotor for long use life.

--With water spray system to clean the mesh.

Zig Zag Label Separator Machine

--High

Efficiency Remover PE PP Flakes In Pet Washing Recycling Flakes

--With Valve To Control The Air Flux Of Blower

--Bottom With Blower Collecting And Blowing Away The Material

Customer Factory

Hot Searches