- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Weight:

-

According different model to

-

Dimension(L*W*H):

-

According to different model

-

Rev speed:

-

0.58-2.85

-

Support:

-

3-4

-

Calcination material:

-

Lime stone, dolomite, magnesite, bauxite

-

Slope:

-

3.5%

-

Capacity:

-

1-40t/h

-

Local Service Location:

-

None

-

Certification:

-

CE ISO BV

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZK

-

Voltage:

-

220V/380V

-

Weight:

-

According different model to

-

Dimension(L*W*H):

-

According to different model

-

Rev speed:

-

0.58-2.85

-

Support:

-

3-4

-

Calcination material:

-

Lime stone, dolomite, magnesite, bauxite

-

Slope:

-

3.5%

-

Capacity:

-

1-40t/h

-

Local Service Location:

-

None

-

Certification:

-

CE ISO BV

Pulverized Carbon Coal Combustion Fired Burner

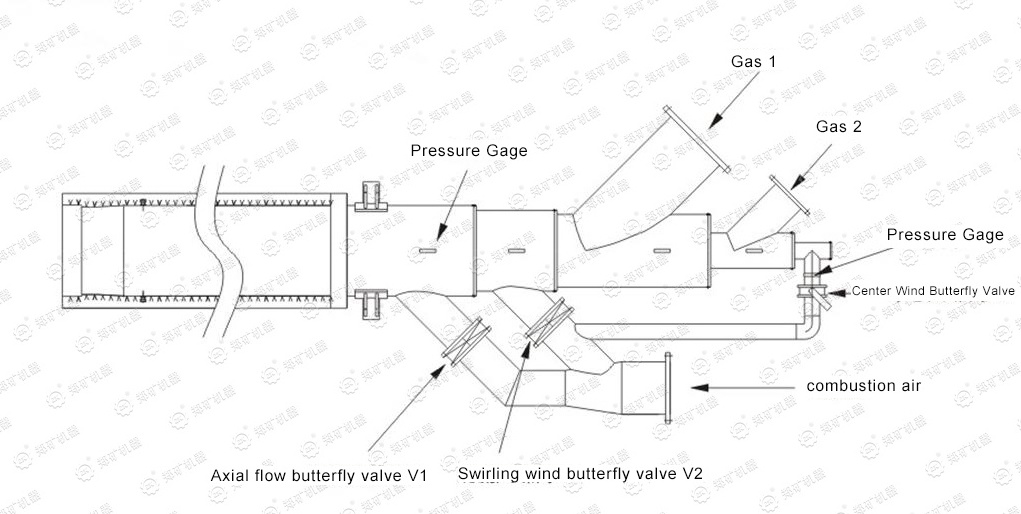

Pulverized coal burner is the key equipment of calcination system in metallurgical, chemical, cement, quicklime rotary kiln, its performance and operation relate to product quality, capacity, energy consumption, environment and so on. Our company design pulverized coal burner is according to different kiln type, different feature of pulverized coal and different technical conditions, with typical structure and reasonable technical parameters, ensuring the pulverized coal, primary air, secondary air mix fully, make high burning efficiency, larger heat intensity, better fire shape and easy control, its widely used in various dry and wet cement rotary kiln, steel sintering pellet rotary kiln, lime rotary kiln, chemical rotary kiln, alumina clinker rotary kiln, power plant boiler and so on.

Application:

Burning system of rotary kiln in power, chemical, metallurgy, construction industry and so on.

1. Reasonable structure design, fire adjustment easily, not only adjustment air volume of axial air, swirling air, but also adjustment outlet section area of axial air ,swirling air and coal air, to reach the goal of change outlet air speed of burner, to ensure fuel burning normally;

2. Less use of primary air, and coal air mix with primary air, secondary air fully, make burning complete, to reduce coal consumption effective;

3. Nozzle is made of special material, heat resistance and replacing easily;

4. Fire cover forming bowleffect, there is not high swirl with fire at beginning, to avoid the peak value of temperature, make the fire temperature distribute uniform and reasonable;

5. Because the combustion air mix pulverized coal fully, the burning is fast and safety, CO and NOX content from kiln tail exit gas are reduced, in favor of equipment operation safety and realize environmentally friendly production;

6. Flange connection for each air pipe of burner, remove and maintenance easily;

7. Adaptable for coal quality, burning low quality coal.

|

Model |

Normal coal consumption(t/h) |

Max. coal consumption(t/h) |

Weight (kg) |

Remark |

|

RSM-1 |

0.5~1.5 |

2.5 |

1200 |

|

|

RSM-2 |

1.5~2.5 |

3.0 |

1500 |

|

|

RSM-3 |

2.5~3.5 |

4.0 |

1950 |

|

|

RSM-4 |

3.0~4.5 |

6.0 |

2100 |

|

|

RSM-5 |

3.0~5.0 |

7.0 |

2300 |

|

|

RSM-6 |

4.0~6.0 |

8.0 |

2500 |

|

|

RSM-7 |

4.5~7.0 |

9.0 |

2800 |

|

|

RSM-8 |

5.0~8.0 |

10.0 |

3000 |

|

|

RSM-9 |

6.0~9.0 |

11.0 |

3200 |

|

|

RSM-10 |

6.5~10.0 |

12.0 |

3600 |