- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

1000W

-

Dimension(L*W*H):

-

15 x5.6x4m

-

Weight (KG):

-

4300

-

Product name:

-

Rolling Mill Machine

-

Commodity:

-

Section Bar Continuous Casting

-

Final product:

-

Flat Steel

-

Keyword:

-

Rebar Continuous Rolling Mill Machine

-

Applicable materials:

-

Construction Bulding Machine

-

Advantages:

-

High Effciency

-

Color:

-

Customized Color

-

Usage:

-

Steel Construction

-

MOQ:

-

1 Set

-

Packaging:

-

Wooden Box

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Feihong

-

Marketing Type:

-

New Product 2023

-

Voltage:

-

380V

-

Power:

-

1000W

-

Dimension(L*W*H):

-

15 x5.6x4m

-

Weight (KG):

-

4300

-

Product name:

-

Rolling Mill Machine

-

Commodity:

-

Section Bar Continuous Casting

-

Final product:

-

Flat Steel

-

Keyword:

-

Rebar Continuous Rolling Mill Machine

-

Applicable materials:

-

Construction Bulding Machine

-

Advantages:

-

High Effciency

-

Color:

-

Customized Color

-

Usage:

-

Steel Construction

-

MOQ:

-

1 Set

-

Packaging:

-

Wooden Box

Introduction & Advantage:

Advantages:

Rebar making machine is a kind of machine use for rolling coil wire from big diameter to small diameter, out put can be ribbed

type or round type. Input diameter could be special making according your local rod material.

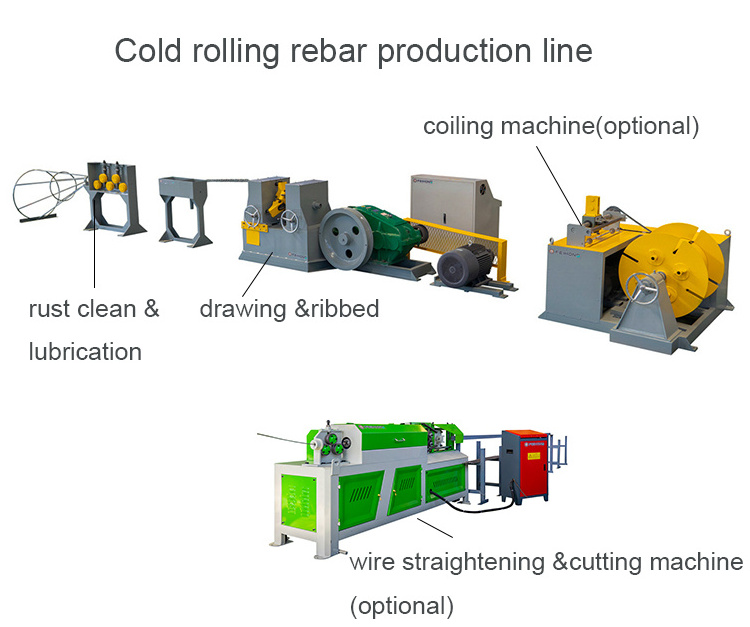

Production flow:

Wire pay-off rack --- R ust remover ---Lubricator---Drawing&Cold rolling ribbed Machine ---Wire coiling machine/Straightening&Cutting Machine

type or round type. Input diameter could be special making according your local rod material.

1. The reducer adopts the international reducer, which has large torque, low noise and strong durability.

2.The double-side reel is coated with cemented carbide or wear-resistant material.

3.Adopting the most advanced frequency conversion , it can save 40-60% of electricity, the lowest power consumption per ton is 8-10 degrees, the line speed can reach 90-230 meters per minute, and the production efficiency is improved by more than 40%. Protection of power transmission and transformation systems and electrical equipment is not damaged, which can greatly extend the service life of the machine.

4.Rolling the shell body is cast with 45# pure steel, never cracking . The rolling mill turbine structure is integrated into one, and it is cast in 45# pure steel. It has no components, large pulling force, wear resistance, continuous teeth and durability.

Production flow:

Wire pay-off rack --- R ust remover ---Lubricator---Drawing&Cold rolling ribbed Machine ---Wire coiling machine/Straightening&Cutting Machine

Technical Parameters

|

Model NO.

|

FHLZ-650

|

|

Raw wire diameter

|

Φ6-10mm

|

|

Finished wire diameter

|

Φ5-9mm

|

|

Rolling speed

|

0-120m/min, inverter speed regulation

|

|

Straightening machine speed

|

0-70m/min,inverter speed regulation

|

|

Cutting length

|

12m

|

|

Power

|

45KW+11KW+5.5KW

|

|

Rolling method

|

Passive single rolling

|

|

Mill cooling method

|

Internal water cooling

|

|

Weight

|

4300KG

|

Details Display

Package&Shipment

Hot Searches