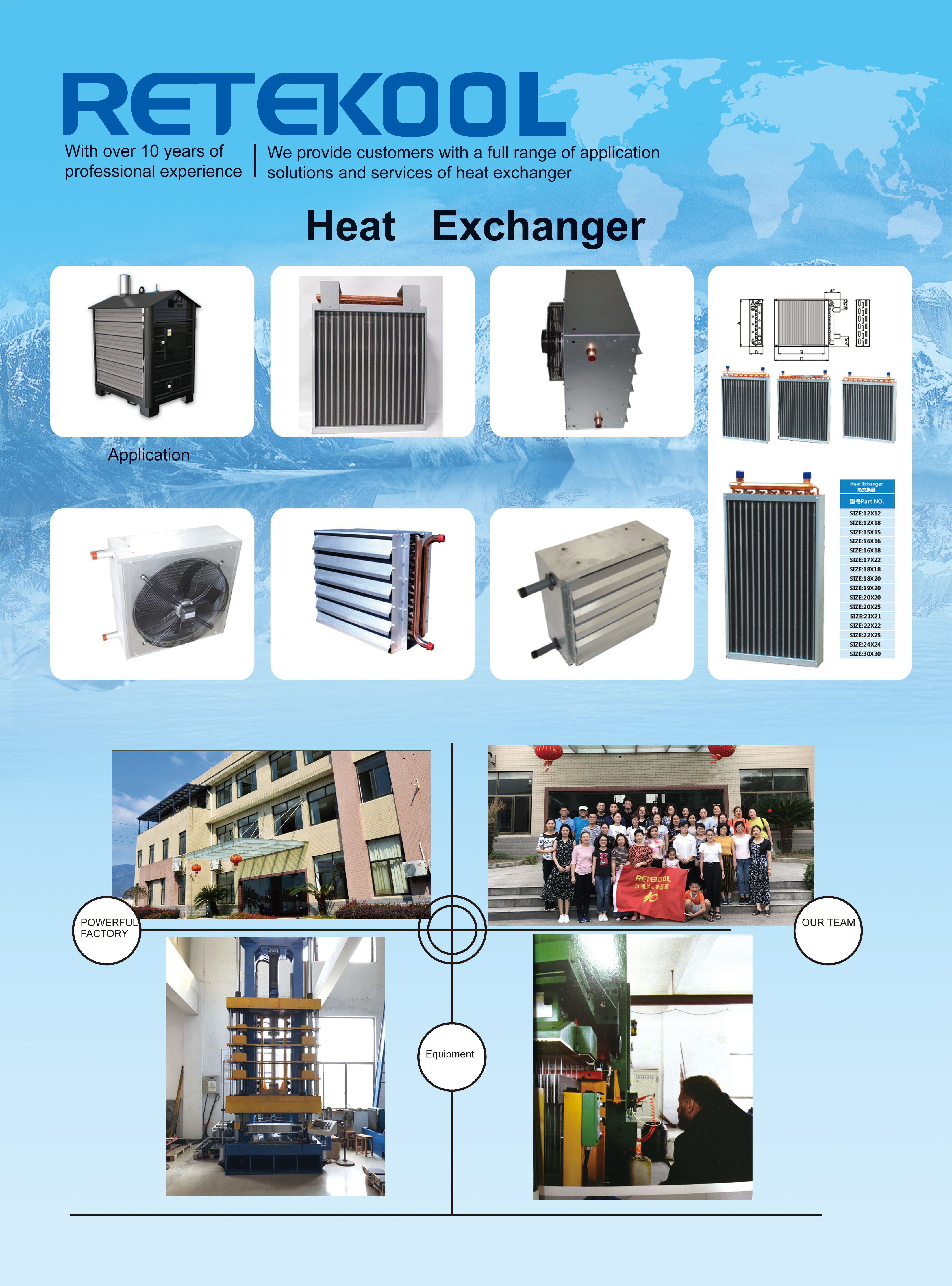

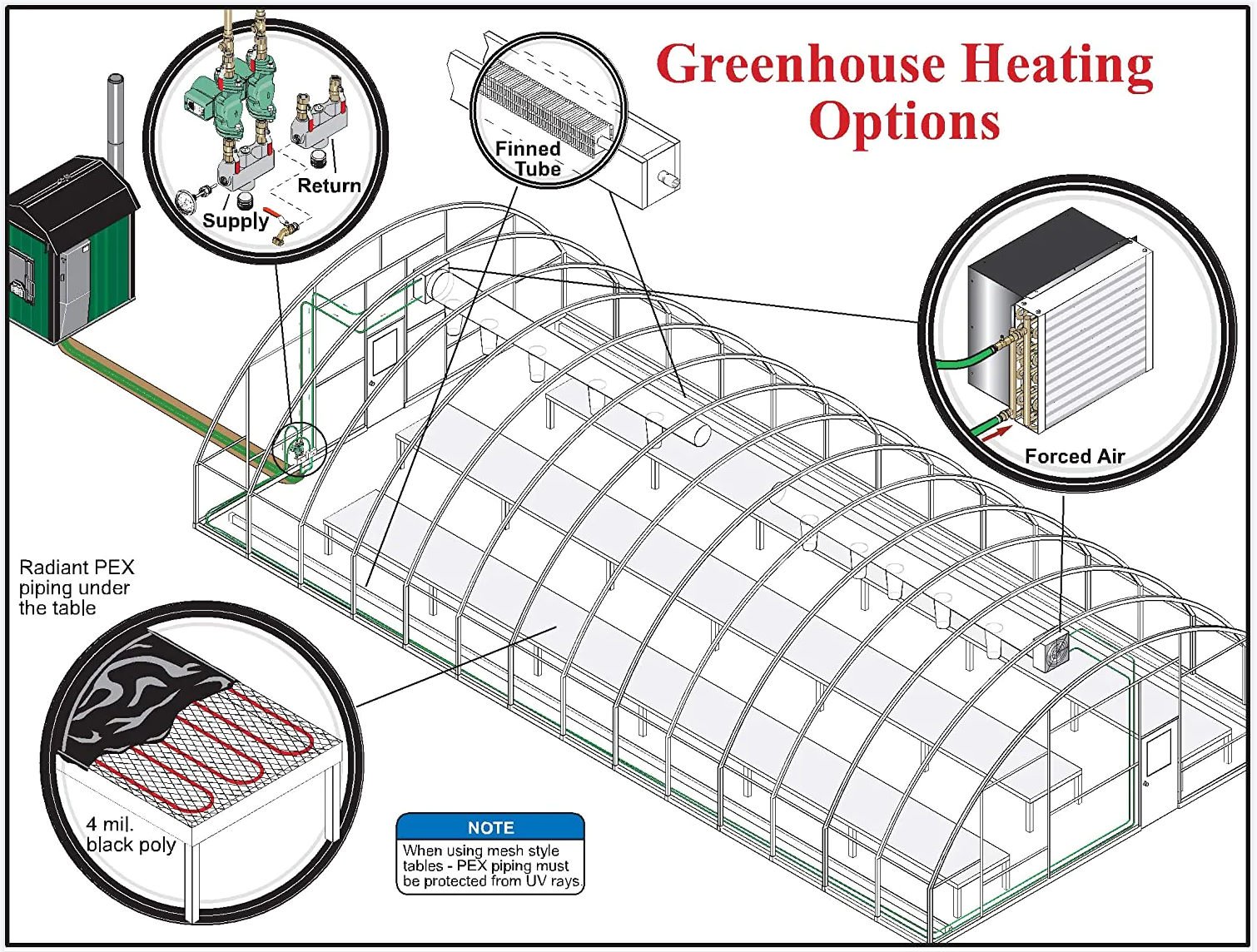

Water to air heat exchangers are used to transfer heat from hot water to air. Water to air heat exchangers are commonly used in outdoor boiler applications when hooking up units to existing forced air furnaces.

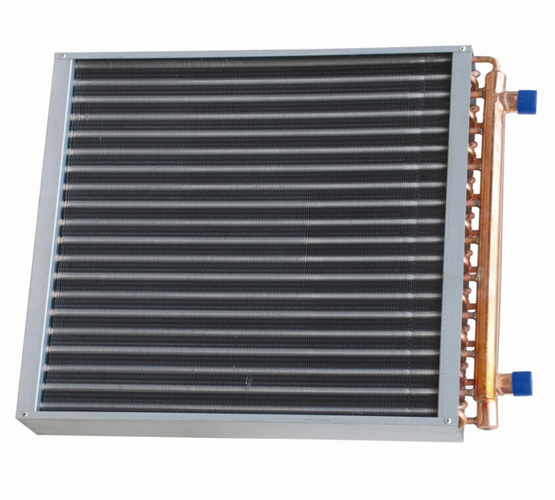

These exchangers are designed to transfer hot water heat through 3/8” seamless copper tubes with high density aluminum fins, with minimal flow resistance. Exchanger housings are manufactured with galvanized steel. Headers are made from copper and have a 1” ID.

Features:

99.9% Pure, Seamless Copper Corrugated Aluminum Plate Fins

Heavy-duty 18-gauge Galvanized Steel Casing

1” Sweat Copper Inlet/Outlet Standard on All Models