- Product Details

- {{item.text}}

Quick Details

-

MF:

-

9000-11-7

-

EINECS No.:

-

259-715-3

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

carboxymethyl cellulose

-

Model Number:

-

cmc carboxymethyl cellulose

-

Appearance:

-

White Powder

-

Application:

-

Food Addtive

-

EC NO.:

-

259-715-3

-

Certification:

-

HALAL

-

Grade:

-

Food Grade

-

Form:

-

Powder Form

-

Shelf Life:

-

2 Years

-

Product name:

-

Cmc Food Grade Carboxymethyl Cellulose Sodium High Quality Thickeners

-

MOQ:

-

1 Ton

Quick Details

-

CAS No.:

-

9000-11-7

-

Purity:

-

high purity, 99%min

-

Other Names:

-

cmc

-

MF:

-

9000-11-7

-

EINECS No.:

-

259-715-3

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

carboxymethyl cellulose

-

Model Number:

-

cmc carboxymethyl cellulose

-

Appearance:

-

White Powder

-

Application:

-

Food Addtive

-

EC NO.:

-

259-715-3

-

Certification:

-

HALAL

-

Grade:

-

Food Grade

-

Form:

-

Powder Form

-

Shelf Life:

-

2 Years

-

Product name:

-

Cmc Food Grade Carboxymethyl Cellulose Sodium High Quality Thickeners

-

MOQ:

-

1 Ton

Product Description

1. Property of CMC -Carboxyl Methyl Cellulose:

Carboxymethyl Cellulose Sodium (CMC-Na) is a cellulose derivative obtained by chemically modificating the natural cellulose. It is one of the most important water soluble polymers with many advantages that other natural or synthetic glues do not have. CMC is white and flowing fine powder. It is tasteless, smelless, mould-proof, non-toxic, non-flammable and easily dissolved in water to become transparent viscose solution. CMC solution has good properties of thickening, adhering, emulsifying, and stabilizing. Membrane forming, moisture-holding, shape-holding, dispersing and anti-enzyme.The solution of CMC can be mixed with dissolvable animal glues, glycerin, sobbitol, Arabic gum, pectin, xanthic gum and dissolvable starch.

2. Usage of CMC -Carboxyl Methyl Cellulose:

1. Oil drilling grade CMC used in fracturing fluid, drilling fluid and well cementing fluid as fluid loss controller and

tackifier. It can protect the shaft wall and prevent mud loss thus enhance recovery efficiency.

2. Detergent grade CMC, when used in liquid, paste detergent, acts as stabilizing agent and thickening agent; When used in

detergent powder, CMC can effectively prevent washes from becoming contaminated after being washed by synthetic detergent.

3. CMC used in textile and dyeing industry as sizing agent and dying adjuvant to make stock limpidity and transparence.

It is easy a good stabilizer of the stock and helps to form film. It is easy to desizing. 4.CMC in Food Industry:CMC is widely

used in frozen desserts, protein food, beverages, icings, dressings, instant noodles, etc.

3. Specification of CMC -Carboxyl Methyl Cellulose:

2. Usage of CMC -Carboxyl Methyl Cellulose:

1. Oil drilling grade CMC used in fracturing fluid, drilling fluid and well cementing fluid as fluid loss controller and

tackifier. It can protect the shaft wall and prevent mud loss thus enhance recovery efficiency.

2. Detergent grade CMC, when used in liquid, paste detergent, acts as stabilizing agent and thickening agent; When used in

detergent powder, CMC can effectively prevent washes from becoming contaminated after being washed by synthetic detergent.

3. CMC used in textile and dyeing industry as sizing agent and dying adjuvant to make stock limpidity and transparence.

It is easy a good stabilizer of the stock and helps to form film. It is easy to desizing. 4.CMC in Food Industry:CMC is widely

used in frozen desserts, protein food, beverages, icings, dressings, instant noodles, etc.

3. Specification of CMC -Carboxyl Methyl Cellulose:

|

Viscosity (1%, Soln.)

|

D.S

|

Purity

|

Application Recommendation

|

|

FOOD GRADE |

30-50

|

0.7-0.9, >0.9

|

Soft Drinking

|

|

|

100-200

|

0.7-0.9, >0.9

|

Juice, Yogurt etc.

|

|

|

300-500

|

0.7-0.9, >0.9

|

Juice, Milk Drinking etc

|

|

|

800-1200

|

0.7-0.9, >0.9

|

Ice Cream, Juice etc

|

|

|

1000-2000

|

0.7-0.9, >0.9

|

Juice, Yogurt, Instant Noodle, etc

|

|

|

2000-3000

|

0.7-0.9, >0.9

|

Ice Cream, Bakery, Soft Drinking, etc.

|

|

|

3000-4000

|

0.7-0.9, >0.9

|

Bakery, etc.

|

|

|

4000-5000

|

0.7-0.9, >0.9

|

Bakery, Meat, etc.

|

|

|

5000-6000

|

0.7-0.9, >0.9

|

Bakery, Meat, etc.

|

|

|

6000-7000

|

0.7-0.9

|

Meat product, etc.

|

|

|

7000-8000

|

0.7-0.9

|

Meat product, etc.

|

|

DETERGENT GRADE

|

5-40

|

0.5-0.7

|

Detergent(Powder), etc.

|

|

OIL DRILLING GRADE |

Apparent Viscosity

|

Fluid Loss

|

Application Recommendation

|

|

|

|

|

|

|

|

≥50

|

≤23

|

Oil Drilling, etc.

|

|

|

≤40

|

≤16

|

Oil Drilling, etc.

|

|

|

≥30

|

≤23

|

Oil Drilling, etc.

|

|

|

≤90

|

≤10

|

Oil Drilling, etc.

|

Applications

Carboxy Methyl Cellulose CMC

(1) Sodium Carboxymethyl Cellulose/CMC for food grade:

CMC is widely used in food industry, it play the roles of taste improvement, thickening and stabilization when used in various kinds of dairy drinks and seasonings. As an additive of molding, taste improvement, anti-fragmentation, water retaining and tenacity strengthening, CMC is also used in ice cream, bread, cake, biscuit, instant noodle and fast paste foods.

(2) Sodium Carboxymethyl Cellulose/CMC for Toothpaste Grade:

CMC has an efficiency of adhesion and molding when used in toothpaste, and stabilizes the quality of toothpaste owing to good compatibleness.

(3) Sodium Carboxymethyl Cellulose/CMC for oil drilling:

CMC and PAC can reduce water loss, and increase viscosity in drilling fluid, cementing fluid and fracturing fluid. They play the roles of protecting the wall of well, taking drilling trifles, protecting drilling bit, preventing mud loss and increasing

drilling rate. Usage: add to mud directly or glue solution preparation.

(4) Sodium Carboxymethyl Cellulose/CMC for Ceramic :

CMC is used for ceramic embryo, glazing pulp and colored glaze in ceramic industry.

(5) Sodium Carboxymethyl Cellulose/CMC for paper making:

In making paper, CMC is used in making pulp so as to improve the retention rate and increase humidity and strength; when used in surface sizing, CMC can improve internal adhesion, decrease printing dust and enhance printing quality as molding reagent. In paper coating, CMC also helps the dispersion and fluidity of paint, improves appearance of paper and smoothness, upgrades optical performance and printing adaptability.

(6) Sodium Carboxymethyl Cellulose/CMC for detergent :

Effectively prevent washes from becoming contaminated after being washed by synthetic detergent.Add 0.5-2 percent only, you can get satisfactory result.Because the action of static between fomite granule with minus charge and CMC molecule with minus charge itself. Make washing liquid more viscouse and the effect of washing more stable.

(7) Sodium Carboxymethyl Cellulose/CMC for for other industries:

As coagulant, water retaining, thickener and binder, CMC is also used in paint, carpet gum, mosquito coil incense, tobacco,

electric welding, textile, battery, printing and others.

(1) Sodium Carboxymethyl Cellulose/CMC for food grade:

CMC is widely used in food industry, it play the roles of taste improvement, thickening and stabilization when used in various kinds of dairy drinks and seasonings. As an additive of molding, taste improvement, anti-fragmentation, water retaining and tenacity strengthening, CMC is also used in ice cream, bread, cake, biscuit, instant noodle and fast paste foods.

(2) Sodium Carboxymethyl Cellulose/CMC for Toothpaste Grade:

CMC has an efficiency of adhesion and molding when used in toothpaste, and stabilizes the quality of toothpaste owing to good compatibleness.

(3) Sodium Carboxymethyl Cellulose/CMC for oil drilling:

CMC and PAC can reduce water loss, and increase viscosity in drilling fluid, cementing fluid and fracturing fluid. They play the roles of protecting the wall of well, taking drilling trifles, protecting drilling bit, preventing mud loss and increasing

drilling rate. Usage: add to mud directly or glue solution preparation.

(4) Sodium Carboxymethyl Cellulose/CMC for Ceramic :

CMC is used for ceramic embryo, glazing pulp and colored glaze in ceramic industry.

(5) Sodium Carboxymethyl Cellulose/CMC for paper making:

In making paper, CMC is used in making pulp so as to improve the retention rate and increase humidity and strength; when used in surface sizing, CMC can improve internal adhesion, decrease printing dust and enhance printing quality as molding reagent. In paper coating, CMC also helps the dispersion and fluidity of paint, improves appearance of paper and smoothness, upgrades optical performance and printing adaptability.

(6) Sodium Carboxymethyl Cellulose/CMC for detergent :

Effectively prevent washes from becoming contaminated after being washed by synthetic detergent.Add 0.5-2 percent only, you can get satisfactory result.Because the action of static between fomite granule with minus charge and CMC molecule with minus charge itself. Make washing liquid more viscouse and the effect of washing more stable.

(7) Sodium Carboxymethyl Cellulose/CMC for for other industries:

As coagulant, water retaining, thickener and binder, CMC is also used in paint, carpet gum, mosquito coil incense, tobacco,

electric welding, textile, battery, printing and others.

More Products

Our main products include sweeteners, preservatives, acidulants, thickeners, flavors, antioxidants, proteins, phosphatases,

vitamins, nutritional supplements and herbal extracts.

Meanwhile, we are continuously introducing more natural, safer, and healthier products to satisfy customers' demands and promoting the development of health industries.

vitamins, nutritional supplements and herbal extracts.

Meanwhile, we are continuously introducing more natural, safer, and healthier products to satisfy customers' demands and promoting the development of health industries.

|

Product Name

|

CAS No.

|

|

Jelly Powder

|

|

|

Agar

|

CAS 9002-18-0

|

|

Arabic Gum

|

CAS 9000-01-5

|

|

Carrageenan

|

CAS 11114-20-8

|

|

CMC/ Carboxymethyl Cellulose Sodium

|

CAS 9000-11-7

|

|

Non-Dairy Creamer

|

CAS 7758-11-4

|

|

Gelatin

|

CAS 9000-70-8

|

|

Guar Gum

|

CAS 9000-30-0

|

|

Gellan Gum

|

CAS 71010-52-1

|

|

HPMC/ Hydroxypropyl Methylcellulose

|

CAS 9004-65-3

|

|

Konjac Glucomannan

|

CAS 37220-17-0

|

|

Pectin

|

CAS 9000-69-5

|

|

Sodium Alginate

|

CAS 9005-38-3

|

|

Xanthan Gum

|

CAS 11138-66-2

|

Packing & Delivery

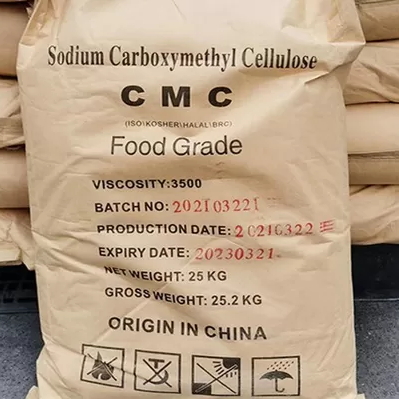

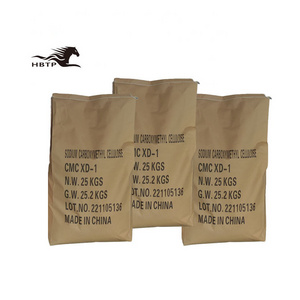

Packaging: 25 kg/bag or according to your request.

Delivery Detail: 7-15 days after confirm order. Some of the products can be supplied in 3-5 days after payments.

Delivery Detail: 7-15 days after confirm order. Some of the products can be supplied in 3-5 days after payments.

Hot Searches