- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5800X2100X1600

-

Year:

-

2020

-

Weight (KG):

-

7800

-

Power (kW):

-

16.5

-

Name:

-

V grooving machine

-

CNC or NOT:

-

CNC

-

Color:

-

Optional

-

Material:

-

Steel Material

-

Function:

-

V-cut

-

Package:

-

nude

-

Grooving Material:

-

MS ,SS

-

Sheet Thickness:

-

6mm

-

Groovering length:

-

4000mm

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SXZG

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5800X2100X1600

-

Year:

-

2020

-

Weight (KG):

-

7800

-

Power (kW):

-

16.5

-

Name:

-

V grooving machine

-

CNC or NOT:

-

CNC

-

Color:

-

Optional

-

Material:

-

Steel Material

-

Function:

-

V-cut

-

Package:

-

nude

-

Grooving Material:

-

MS ,SS

-

Sheet Thickness:

-

6mm

-

Groovering length:

-

4000mm

auto cnc V cutting cut grooving machine for stainless steel metal sheet, V groover machine

Grooving machine

Product Description

Advantages: conventional machine is clamps hold the sheet metal moving over the working table, so the sheet surface is very easy to be scratched.

Now this machine's biggest advantage is sheet metal fixed, has no relative motion. the work piece is protected perfectly, especially for use in mirror stainless steel plates on decoration, and so that the machine has a high processing speed.

Hydraulic v grooving machine Frame structure with the overall table, mobile gantry beam also welded frame structure, the implementation of the overall welding, tempering after welding the whole, all to ensure the overall good rigidity, have to ensure that the future use is not deformed.

Detailed Images

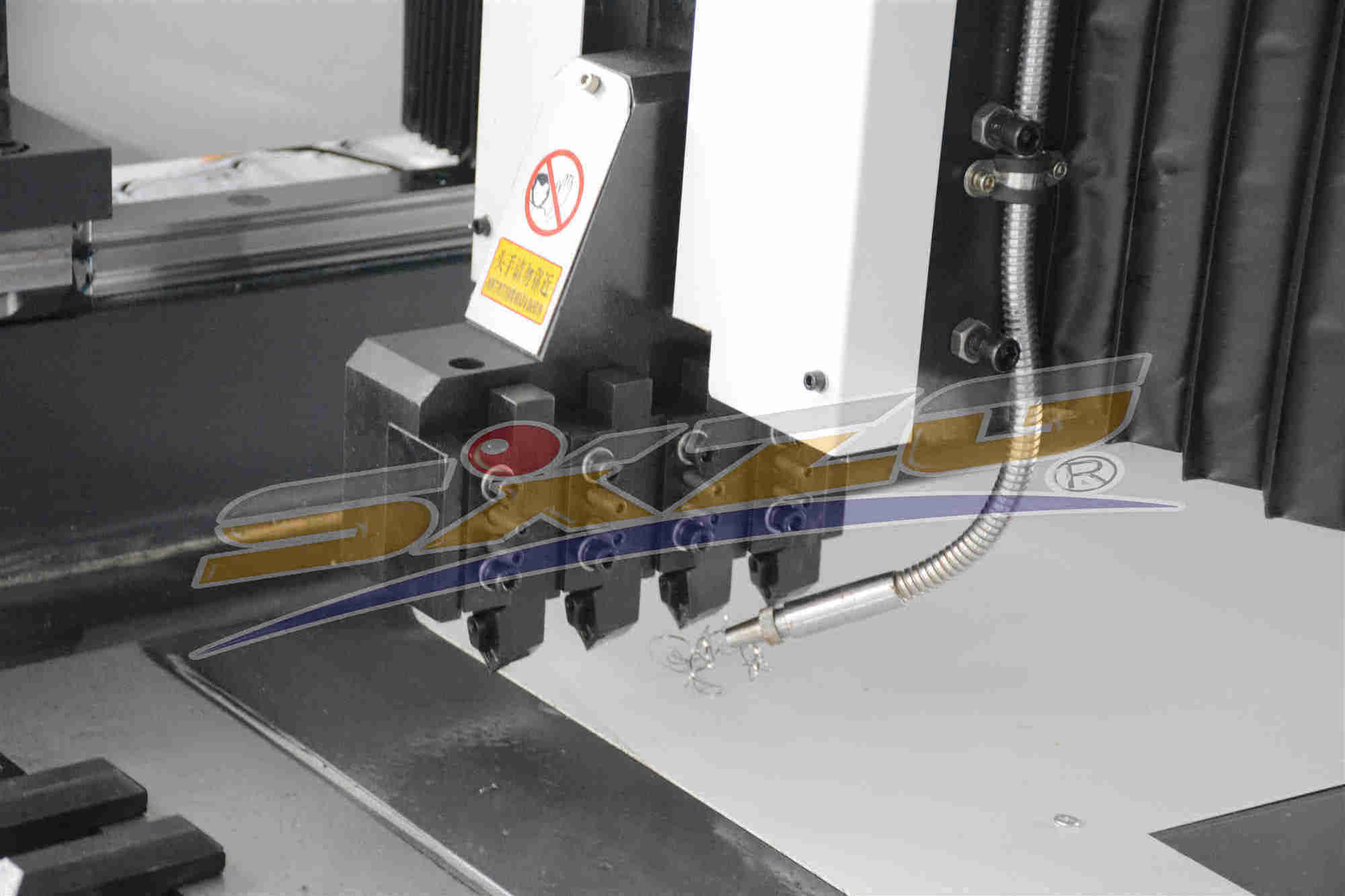

CNC V Grooving Machine Main feature:

1.1 sheet metal slotting machine frame and the beam are all box-shaped. After finite element optimization design, the all-steel welding is tempered to eliminate residual stress, and the overall rigidity is good and the precision is good.

1.2 stainless steel V grooving machine with 4 control axes, hydraulic hold-down device, the gantry and tool holder make round-trip move together when working.

1.3 V groover machine use ball screw & roller heavy-duty guide rail, D1N6-grade precision helical gear, planetary reducer: balance, accurate

1.4 CNC open controller, supporting full-automatic operation, 4-blades can run simultaneously significantly improves the grooving efficiency.

1.5 metal sheet slotting machine adopt Taiwan industrial-control controller and Japan Panasonic closed-loop servo system: easy, flexible, fast, efficient and low noise.

1.6 Vslotting machine equipped with automatic lubrication system: low wear, fine processing, ensuring machining accuracy and high dynamic response characteristics.

Workpiece Samples

Size Information

|

Item

|

Parameter

|

|

Grooving width

|

1500 mm

|

|

Grooving length

|

4000 mm

|

|

Grooving thickness range

|

0.6-4 mm

|

|

Minimum grooving width to the side

|

8 mm

|

|

Beam moving(forward and backward) speed(X Axis)

|

≤70m/min

|

|

Beam moving(left and right) speed(Y1 Axis)

|

≤70m/min

|

|

Clamping moving(left and right)spped(Y2 Axis)

|

≤12m/min

|

|

Cutter holder(up and down) moving speed(Z Axis)

|

≤8m/min

|

|

X Axis motor power

|

5.5 KW

|

|

Y1/Y2 Axis Servo motor power

|

1 KW

|

|

Z Axis Servo motor power

|

≤12m/min

|

|

Hydraulic motor power

|

2.2 KW

|

|

Hydraulic pressure

|

10 Mpa

|

|

Air pressure

|

0.6 Mpa

|

Customer Photos

Related Products

Hot Searches