Name:

air cyclinder

Brand:

JELPC CORPORATION

Advantage:

air pressure inoculation, assure noculation accuracy.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

42PT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

culture medium:

-

egg embryo

-

Name:

-

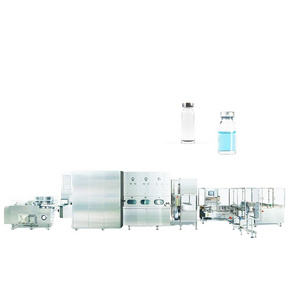

egg embryo inoculating machine

-

Function:

-

Making vaccine

-

Application:

-

animal vaccine

-

Material:

-

Stainless Steel 316

-

control:

-

PLC Siemens

-

Advantage:

-

High Accurate

-

Warranty:

-

One Year

-

Product name:

-

bird flu vaccine machine

Quick Details

-

Properties:

-

Diagnosis & Injection

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

WANDA

-

Model Number:

-

42PT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

culture medium:

-

egg embryo

-

Name:

-

egg embryo inoculating machine

-

Function:

-

Making vaccine

-

Application:

-

animal vaccine

-

Material:

-

Stainless Steel 316

-

control:

-

PLC Siemens

-

Advantage:

-

High Accurate

-

Warranty:

-

One Year

-

Product name:

-

bird flu vaccine machine

Product Description

In the production of traditional embryotoxic vaccines, all manual operations are used, the production efficiency is low, the labor intensity is large, and the uniformity of product quality is difficult to ensure. Such a production process is not conducive to modern management, especially the rapid development of science and technology today. The era calls for reform and innovation, changes the existing production situation, and automates the production process.

In the production of embryotoxic inactivated vaccine, due to the use of automated equipment, the traditional production process has been completely changed, the process is simple, the footprint is reduced, the production capacity under the same production area is increased by 4 times, and the air-conditioning energy is saved. There is no need to set a hundred zones. Since the equipment is connected to different production areas, the automatic transfer of chicken embryos from one area to another produces a lot of manpower. Since the processing of the chicken embryo is completely completed by the equipment, the pollution is reduced, the product quality is improved, and the uniformity of the product quality is achieved.

Characteristics:

1. Automate the whole process of inoculation

2. Process aseptic environment

3. save human effort

4. Improve chicken embryo yield and potency

5. easy to use

6. Small use space

7. Localization of all accessories

8. Consumption is low and clean

9. Meet GMP requirements

10. Embryo vaccine production line operation

Basic structure and working principle

The semi-automatic egg embryo inoculating machine only contains the components of the inoculation device. The electrical control of this part consists of programmable controller and electrical actuators.

1. The inoculation device consists of an inoculation cylinder, a perforating cylinder, an inoculation cylinder, and a poisoning cylinder. The inoculation bracket cylinder controls the perforation height of the egg embryo through the cylinder positioning screw. The punching cylinder controls the punching needle to complete the punching of the egg embryo. The needle cylinder controls the inoculation needle into the egg embryo. The poisoned cylinder controls the inoculum of the egg embryo.

2. The inoculation pressure tube is connected to the seed bottle through a silicone tube, and the injecting gas pressure is

connected to the seed bottle through a filtering device.

|

No

|

Item

|

42PT

|

84PT

|

|

|

1

|

Egg tray specifications

|

42 pieces

|

84 pieces

|

|

|

2

|

Egg embryo size

|

the same batch of eggs height ± 1 mm

|

|

|

|

3

|

Inoculation accuracy

|

±0.01

|

±0.01

|

|

|

4

|

Material

|

The parts contacting product is made of 316L stainless steel, other parts use 304 stainless steel. Machine frame countertop and

other components use 304 stainless steel and Aviation aluminum plate( model 7077) |

|

|

|

5

|

Control system

|

PLC Siemens

|

PLC Siemens

|

|

|

6

|

Structure

|

No dead angle, easy to clean

|

|

|

|

7

|

laminar flow hood

|

Hundred level, reach high level purification

|

|

|

Main Features

Main Features

Name: needle pan and shelf

Brand: WANDA

Advantage : stainless steel 316L, high standard polishing, assure GMP standard

Machine Parts

Name:

needles

Brand:

WANDA

Advantage

:

SUS316L stainless steel,

Quantitative dosing, according to customer requirement

Main Features

Name:

PLC Control

Brand:

Siemens

Advantage

:

Auto operation, Siemens brand, high quality touch screen.