- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380v/420v

-

Dimension(L*W*H):

-

according to capacity

-

Marketing Type:

-

discount

-

Weight (KG):

-

68000 kg

-

Keywords:

-

AAC Block plant

-

Keywords 2:

-

AAC production line

-

Keywords 3:

-

AAC Machine

-

Product Name:

-

aac plant

-

Name:

-

AAC making Machine

-

Raw material:

-

sand, fly ash, lime, cement

-

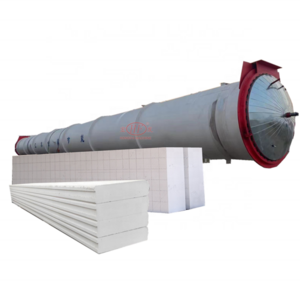

Autoclaved:

-

yes

-

with steam boiler:

-

yes

-

Local Service Location:

-

Russia/Kazakhstan/Uzbekistan/Egypt

-

Certification:

-

ISO, CE

Quick Details

-

Type:

-

AAC Block making machine

-

Brick Raw Material:

-

Fly Ash, cement, lime, sand

-

Production Capacity (Pieces/8 hours):

-

10,000~600,000 cbm per year

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380v/420v

-

Dimension(L*W*H):

-

according to capacity

-

Marketing Type:

-

discount

-

Weight (KG):

-

68000 kg

-

Keywords:

-

AAC Block plant

-

Keywords 2:

-

AAC production line

-

Keywords 3:

-

AAC Machine

-

Product Name:

-

aac plant

-

Name:

-

AAC making Machine

-

Raw material:

-

sand, fly ash, lime, cement

-

Autoclaved:

-

yes

-

with steam boiler:

-

yes

-

Local Service Location:

-

Russia/Kazakhstan/Uzbekistan/Egypt

-

Certification:

-

ISO, CE

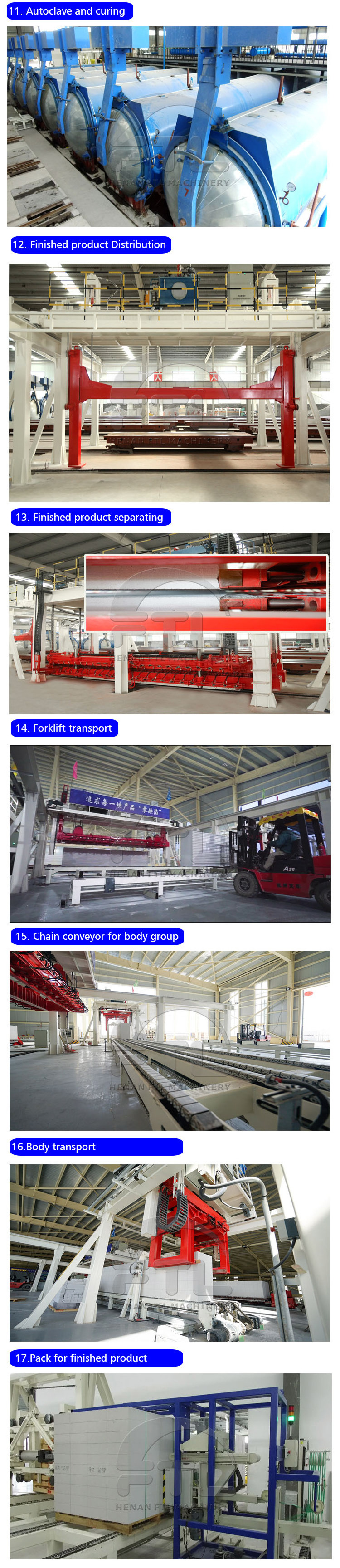

German technology 10,000~300,000 m3 sand aac block production line

Autoclaved Aerated Concrete (AAC) is a siliceous material (sand, fly ash and silicon tailings such as waste porcelain clay, stone processing waste materials, blast furnace slag, etc.) and calcareous materials (lime, cement) as the main raw material, mixing fat gas agent (aluminum powder), by ingredients, mixing, casting, pre-raising, cutting, autoclave, curing process made of light porous silicate products, because by the hair contains a lot of gas even after the small pores, hence the name of aerated concrete.

The normal production capacity:

|

Annual Capacity ( 300days ) |

Power |

Daily Capacity |

Cycle Time |

No. of Autoclaves |

plant area (m2) |

|

50,000m ³ /year |

400KW |

166 m ³ /day |

8 hours |

2 |

2000 |

|

100,000m ³ /year |

500KW |

333m ³ /day |

8 hours |

4 |

2000 |

|

150,000m ³ /year |

630KW |

500m ³ /day |

8 hours |

6 |

2500 |

|

200,000m ³ /year |

720KW |

666m ³ /day |

8 hours |

8 |

3000 |

|

300,000m ³ /year |

1186KW |

1000m ³ /day |

8 hours |

6(D2.85*32.5) |

3500 |

Main Equipments in AAC Production Line:

| 1. Belt Conveyor | 2. Batching Machine | 3. Roller Screen | 4. Slurry Tank | 5. Wet Ball Mill |

| 6. Jaw Crusher | 7. Dust Remover | 8. Bucket Elevator | 9. Lime Stone Silo | 10. Dry Ball Mill |

| 11. Lime Powder Silo | 12. Cement Silo | 13. Screw Conveyor | 14. Slurry Storing Tank | 15. Scale for Slurry |

| 16. Scale for Lime&Cement | 17. Ferry Cart | 18. Tilting Crane | 19. Cutting Machine | 20. Cutting Machine |

| 21. Tilting Crane | 22. Steam Cart | 23. Autoclave | 24. Crane after Autoclave | 25. Product Crane |

Advantages of the aac block

1. Lightweight : Porosity achieve 70% to 85%, volume density is generally 500 ~ 900kg/m3, as 1/5 of general concrete the 1/4of clay, the 1/3 of hollow brick, and similar with wood can float in water. It can reduce building weight, reduction in the cost of integrated building.

2. Fireproof : Most of the major raw materials is inorganic materials, so it has good fire resistance, and do not emit harmful gases when meet fire. Fire 650 degrees, as a refractory material, the thick up of 90mm walls can reach to 245 minutes fire resistance, 300mm thick up wall can reach to 520 minutes fire resistance.

3. Sound insulation : Due to a unique porous structure, so it has a sound absorption capacity. The sound absorption capacity can reach of 10mm thick wall up to 41 db.

4. Insulation : As the material inside has a large numbers of the pores and porous, which has a good thermal insulation properties. The Thermal conductivity is 0.11-0.16W/MK, as 1/4-1/5 of brick. Typically, the insulation effect of 20cm thick aerated concrete wall is equivalent to 49cm thick solid brick walls ordinary.

5. Permeability : Result of material by the composition of many independent small pores, the moisture absorption is slow, in the volume of absorbent is 5 times of clay saturation do. When used in the bathroom, the wall can be treated to interface directly paste tiles.

6. Anti-seismic: The same building structure, improve the two seismic than the brick level.

7. Green : Manufacturing, transportation, all use the process of pollution, to protect arable land, saving energy, is one kind of a green building material.

8. Durability : material strength is stability, in the specimens tested after one year of atmospheric exposure; the intensity increased by 25%, and remained stable after ten years.

9. Economies : An integrated lower cost than using more than 5% of solid clay bricks, and can increase the usable area, greatly enhance the utilization of floor space.

About us:

Customers' visiting: