- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TSE

-

Voltage:

-

240v/380v/415v/450v

-

Dimension(L*W*H):

-

1200x700x15000mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Elevator name:

-

grain bucket elevator for sale

-

Elevator application:

-

for grain transportation

-

Raw materials:

-

Galvanized steel sheet / carbon steel /stainless steel

-

Coating mass:

-

Hot dip galvanized coating / surface painting

-

Production standard of elevator:

-

Australian standard / Chinese standard

-

Capacity of bucket elevator:

-

5t/h ----300t/h

-

Motor and gearbox:

-

ABB/ SIMENS/ SEW elevator motor and gearbox

-

Inspection devices:

-

Inspection window at the booth of elevator

-

Elevator warranty:

-

Free service for one year after commissioning

-

Certification:

-

ISO9001

Quick Details

-

Power:

-

15KW

-

Warranty:

-

1 Year

-

Width or Diameter:

-

OTHER

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TSE

-

Voltage:

-

240v/380v/415v/450v

-

Dimension(L*W*H):

-

1200x700x15000mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Elevator name:

-

grain bucket elevator for sale

-

Elevator application:

-

for grain transportation

-

Raw materials:

-

Galvanized steel sheet / carbon steel /stainless steel

-

Coating mass:

-

Hot dip galvanized coating / surface painting

-

Production standard of elevator:

-

Australian standard / Chinese standard

-

Capacity of bucket elevator:

-

5t/h ----300t/h

-

Motor and gearbox:

-

ABB/ SIMENS/ SEW elevator motor and gearbox

-

Inspection devices:

-

Inspection window at the booth of elevator

-

Elevator warranty:

-

Free service for one year after commissioning

-

Certification:

-

ISO9001

Grain storage grain silos (also called grain storage bins) are the efficient and economical facilities to handle your grains, which offer protection from outside insects and other affects as well as provide handling management conveniently.

chain bucket elevator

Bucket elevators are powerful mechanism for hauling flowable bulk grain vertically, it is widely used in broad range of flowable materials applications for grain storage silos . The reliable Shelley bucket elevator is designed with reasonable running structure, highly resistant anti-wear steel and high-strength plastic bucket, which makes it easy for installation and longer trouble-free life span.

The Bucket Elevator consists of a series of buckets attached to a belt or chain with pulleys or sprockets located at the top and bottom of the unit. The buckets are located in a casing or housing to contain the material. Bulk materials are loaded into each bucket as the bucket moves past an inlet point. Shelley company could designs and manufactures a wide variety of bucket elevators based on the characteristics of the bulk material and the process requirements.

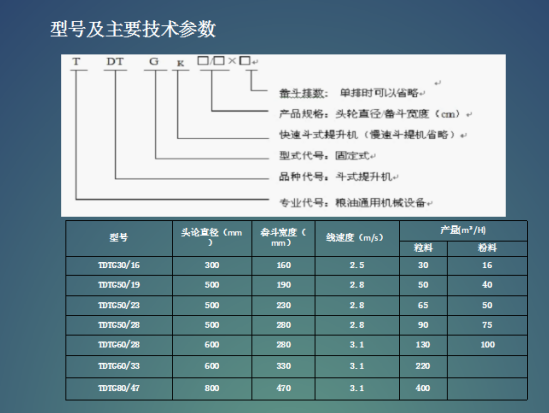

Specifications of chain bucket elevator

| For more product information , please click | CONTACT US > |

Features of chain bucket elevator

1. Bucket elevators are capable for different small particle materials handling, including powder, granular and massive materials

2. Big capacity. The series of bucket elevator has a variety of specifications. The lift range is 10-800 m³ / h.

3. Small power consumption. Use intensive layout of the large-capacity transportation. chain speed medium, to enhance the amount of the capacity. So driving low energy consumption.

4. Long service life

5. High hoisting height. This series of chain hoist speed moderate, smooth operation, and adopts the plate chain high strength wear resistant chain, so can reach high hoisting height (up to 40-50m)

6. Good sealing, less environmental pollution

7. Easy to operation, convenient maintenance, less wearing parts

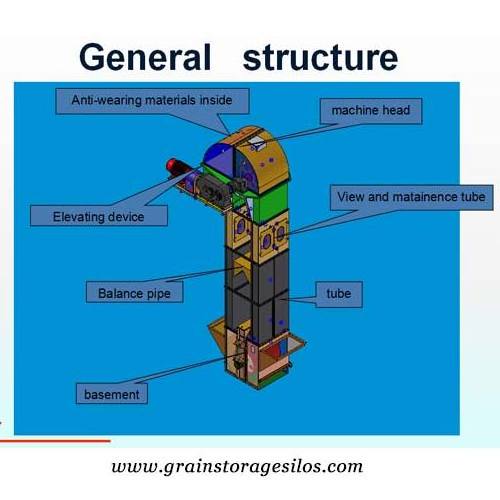

Structures of chain bucket elevator

The main structure of grain bucket elevator includes bucket, bucket belt, head, head wheel, booth, transporting wheel, tension device, input bucket, exiting mouth.

1. HDPE buckets to contain the material;

2. Bucket belt (rubber belt or nylon belt) to carry the buckets and transmit the pull;

3. Head wheel with rubber;

4. Means to drive the belt;

5. Accessories for loading the buckets or picking up the material, for receiving the discharged material, for maintaining the belt tension and for enclosing and protecting the elevator.

We also provide relevant supporting products

Accessory Equipments:

- Bucket Elevator with capacity from 1 tone/hour to 400 tone/hour - Chain Conveyor with capacity from 1 tone/hour to 400 tone/hour - Screw Conveyor with capacity from 1 tone/hour to 200 tone/hour - Elevator Towers - Electrical and Manuel controlled Slide gates - Distributors with 1 in 2/3/4/5/6 out - Catwalks - Spout Pipes

Machines:

- Drying Machines ( Tower Type and Horizontal Type ) with capacity from 5 tone/hour to 50 tone/hour

- Mill Machines with capacity from 5 tone/hour to 50 tone/hour

- Pellet Machines with capacity from 5 tone/hour to 50 tone/hour

-Level sensors, aeration system with centrifugal fan, temperature control system and sweep auger, dedusting system as an option.

Installation can be carried out in different ways

*If the client wants to install 10ton-1500ton steel hopper bottom grain silos by themselves, we could offer detailed instruction, and we'll give our quickest response to deal with any question in the process.

*We could also send our engineer to supervise the installation process. The client could find local workers for the installation work and our engineer will help them during the process.

*If the client needs, we could send our installation team for the whole installation issue.

FAQ

Q 1 : What certifications do you have?

A1: ISO certification , BV certification and CE certification .

Q2: What is the export customs code of your product?

A2: 7309000000

Q3. What is your payment method?

A3: 30% advance payment for foreign projects, full delivery.

Q4.Can you do custom design and production?

A4: The selection of prefabricated steel 10ton-1500ton steel hopper bottom grain silos is fixed, and the diameter cannot be changed. If other 10ton-1500ton steel hopper bottom grain silos such as flour 10ton-1500ton steel hopper bottom grain silos, cement 10ton-1500ton steel hopper bottom grain silos, and square 10ton-1500ton steel hopper bottom grain silos are required, they can be customized for production.

Q 5. About installation, how to install? How much is the installation fee?

A5: Abroad: Generally 1-2 people guide the installation, each person 100 dollars per day.

Q6: What materials are used for your steel warehouse?

A6: At the top of the warehouse, the barrel is a galvanized steel sheet, the cone bottom with a diameter of 4.5m is galvanized sheet, and the cone bottom with a diameter of 4.5 to 11m is a carbon steel sheet.

Q7: What are the types of steel 10ton-1500ton steel hopper bottom grain silos in your company?

A7: We mainly have cone bottom steel 10ton-1500ton steel hopper bottom grain silos, flat bottom steel 10ton-1500ton steel hopper bottom grain silos, cement 10ton-1500ton steel hopper bottom grain silos and flour 10ton-1500ton steel hopper bottom grain silos.

Q8: Can you provide supporting equipment? What can be provided?

A8: Yes. Cleaning equipment includes cleaning screen, vibrating screen, dust removal equipment, and conveying equipment including hoist, scraper, belt conveyor, and screw conveyor.