- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1450*800*1400

-

Year:

-

2021

-

Warranty:

-

2 years

-

Power (kW):

-

2.2 kW

-

Weight (KG):

-

1100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Used for:

-

Vulcanizing Tire Tread

-

colour:

-

all colour

-

voltage:

-

customized

-

Power(W):

-

2.2 KW

-

Weight:

-

1100kg

-

Tyre type:

-

all

-

Usage:

-

Rubbr Vulcanization

-

Advantage:

-

Efficient

-

Motor:

-

Chinese Famous Brand

-

Marketing Type:

-

New Product 2021

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HONGHESHENG

-

Voltage:

-

380V/220V/450V

-

Dimension(L*W*H):

-

1450*800*1400

-

Year:

-

2021

-

Warranty:

-

2 years

-

Power (kW):

-

2.2 kW

-

Weight (KG):

-

1100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Used for:

-

Vulcanizing Tire Tread

-

colour:

-

all colour

-

voltage:

-

customized

-

Power(W):

-

2.2 KW

-

Weight:

-

1100kg

-

Tyre type:

-

all

-

Usage:

-

Rubbr Vulcanization

-

Advantage:

-

Efficient

-

Motor:

-

Chinese Famous Brand

-

Marketing Type:

-

New Product 2021

-

Certification:

-

CE ISO

why choose us:

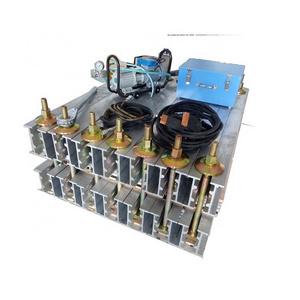

1 manufacturer direct sale, can ensure delivery time and quality.

2 plunger diameter difference is very small, which ensure pressure.

3 our vulcanizing press is equiped with PLC system . automatic controling temperature and pressure, automatic alarm, automatic loading ,emergency stop ,digital readout and son on.

4 low noise, no oil leakage, no pressure off.

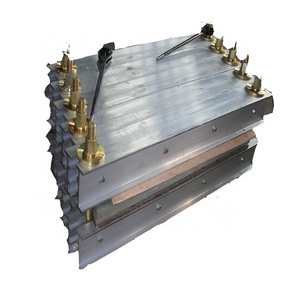

5 small temperature difference of hot plate,

Plate temperature difference: ±1 °C, which follows the national standard.

6 the parallelism differnce does not exceed ±0.01-0.02mm

7 hot plate use high quality carbon steel Q-235 material.

7 heating method according to your request : electricity , steam heating , conduction oil heating .

8 we can make machine according to the your request.

9 we can give a good discount according to your quantity

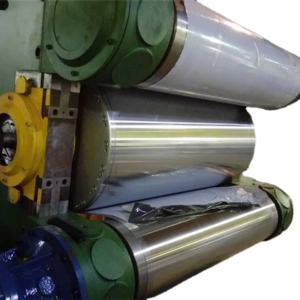

detailed pictures

Qingdao Honghesheng Industry Co., LTD, which is located in the west coast of Qingdao economic district, with 10 million registered capital. The company covers an area of 5000 square meters with 26 professional and technical staffs and 5 senior engineers. The technical staffs have working experience in large tire enterprise who can design more suitable equipment for the customer as for tire production process. Also they can provide new factory site planning and other services.

The company’s main products are: Rubber kneader, rubber mixing mill, rubber sheet cooling machine, inner tube production line,tyre production line, vulcanizing press, waste tyre recycling plant…The products have been sold to 20 provinces in China and exported more than 10 countries and areas. The stable quality and timely service obtain the positive feedback and are high praised.

“Quality, integrity, innovation, service”is the aim of our company. We would like to promote cooperation with national new and old customers and foreign clients and seek common development.

1. Q: Are you a manufacturer or training company?

A: We are the manufacturer. We have our own plant,worker and techniques research developing department .

2 .Q: Where is your factory located? How can I visit there?

A: Our factory add is Tieshan industrial Park, Jiaonan, Qingdao, Shandong province, China.

Nearest airport is Qingdao liuting international airport

Kindly send plane information in advance, so that we can pick you up at the airport, and book hotels as you require.

3. Q: What are your hot sale machine?

A: Our rubber and plastic machines are popular in the foriengn market. And main products are tyre recyling plant ,press machine and other machine.

4. Q: How does your factory do regarding quality control?

A: Quality is priority and we have our own quality control department. We win make a strick inspectin before the machines leave the factory.

5 .Q: Are the techncal parameter is fixed?

A: Basically, each model corresponding to the related machine. But we can design different type machine according to the client’s requirement.

Leave your cellphong? Skype? whatsApp?viber? so that we can talk efficiently.