* Safety:

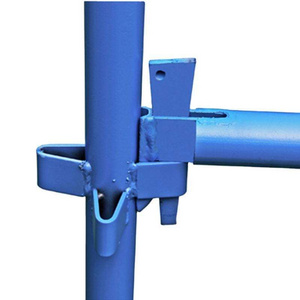

Provides safe V-lug connections of high degree of rigidity to scaffold; High load rating and high degree of

rigidity;Provides safe guardrails, mesh panels, toe boards and anti-slip planks for the working platform.Provides high load capacity for shoring.

* High efficiency:

High speed of erection and dismantling; High degree of standardisation and modular components.

* Easier:

No loose fittings, easy for storage and transportation; Gravity wedges pin locking can avoid human error and simplify erection and dismantling; Easily fit to various layout and height.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Building Construction, Building Construction

-

Design Style:

-

Traditional

-

Type:

-

Kwikstage Scaffolding Board Bracket

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Shuangma

-

Model Number:

-

KS.HUB

-

Product name:

-

Kwikstage Scaffolding Board Bracket

-

Usage:

-

Flatform Extention

-

Advantage:

-

Flexible

-

Standard:

-

AS/NZS1576.3

-

Material:

-

Q235 Steel

-

Size:

-

for 1/2/3 Boards

-

Surface treatment:

-

Hot Dip Galvanized, painted, powder coated

-

Payment terms:

-

30% T/T Depoist

-

MOQ:

-

1*20GP Mixed Size Acceptable

Quick Details

-

Warranty:

-

3 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

Building Construction, Building Construction

-

Design Style:

-

Traditional

-

Type:

-

Kwikstage Scaffolding Board Bracket

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Shuangma

-

Model Number:

-

KS.HUB

-

Product name:

-

Kwikstage Scaffolding Board Bracket

-

Usage:

-

Flatform Extention

-

Advantage:

-

Flexible

-

Standard:

-

AS/NZS1576.3

-

Material:

-

Q235 Steel

-

Size:

-

for 1/2/3 Boards

-

Surface treatment:

-

Hot Dip Galvanized, painted, powder coated

-

Payment terms:

-

30% T/T Depoist

-

MOQ:

-

1*20GP Mixed Size Acceptable

Our Advantages

|

1

|

35 years of scaffolding experience and construction services.

|

|

2

|

Great production capacity of more than 1000tons per month which ensure faster delivery.

|

|

3

|

Modern factory and before/after sales technical supports.

|

|

4

|

Good reputation and relationship with China's top shipyard companies.

|

|

5

|

Varied types of scaffolding supply to satisfy different demands of clients.

|

|

6

|

Has own Powder Coating production line, to provide fine coating for scaffolding.

|

Product Description

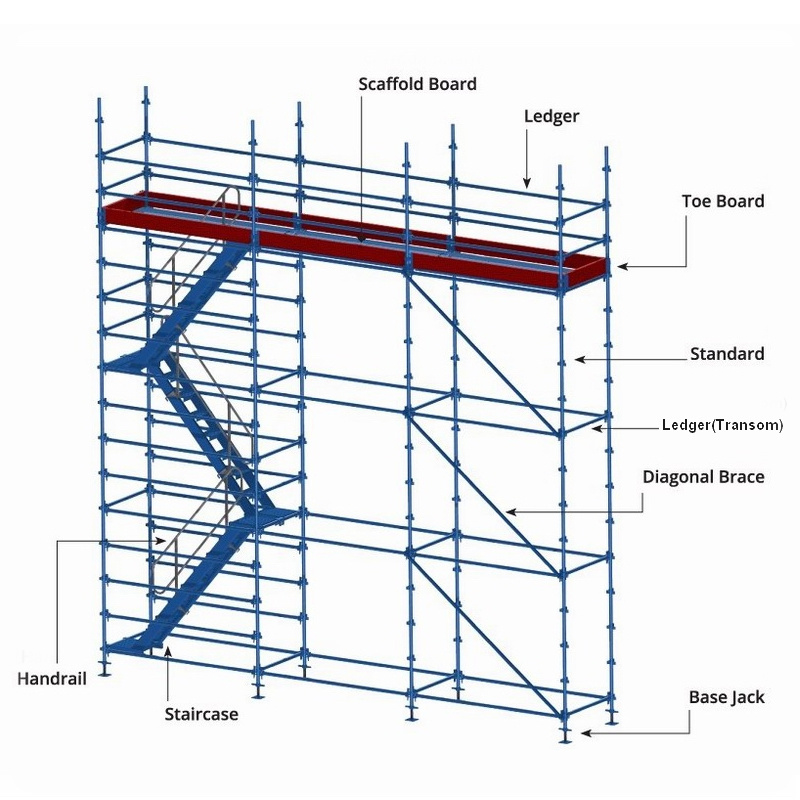

KWIKSTAGE SYSTEM SCAFFOLDING

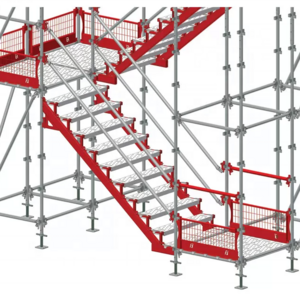

Kwiksatge System Scaffolding is a heavy duty modular scaffold system which is the most common method of access today for work at heights. It comprises of a vast array of easy change components that when used in conjunction with one another, provides an extremely adaptable scaffold solution, whether it be for residential, commercial or industrial use. Its vertical post is made by O.D. 48.3mm x 4mm thickness high quality steel tubing which can provides safety and heavy duty support for scaffolding, and complies to AS/NZS 1576 and AS 1577 requirements.

Advantages of Kwikstage Scaffolding:

Kwikstage Scaffolding Erecting Instruction:

Kwikstage Scaffolding

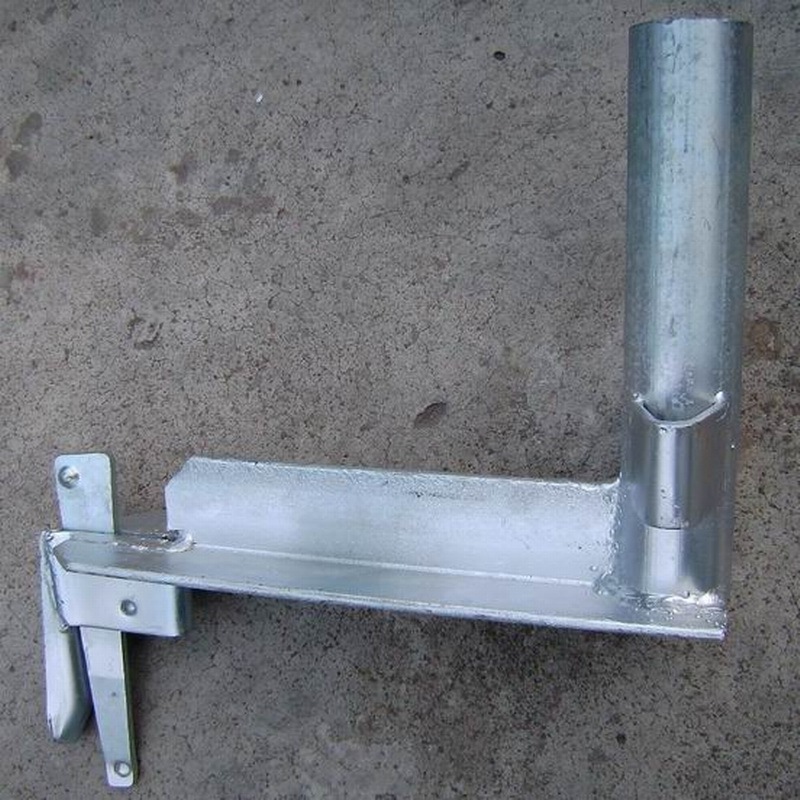

Hop Up Bracket / Board Bracket with Post and Spigot

|

Code

|

Description

|

Material

|

Weight(kg)

|

Weight(lbs)

|

Weight (lbs)

|

|

KS.HUB.1P

|

Hop Up Bracket 1 Board w/Post

|

Angle steel 50x5mm; Q235

|

4.51

|

9.94

|

50.80

|

|

KS.HUB.2P

|

Hop Up Bracket 2 Board w/Post

|

|

8.30

|

18.31

|

44.63

|

|

KS.HUB.3P

|

Hop Up Bracket 3 Board w/Post

|

|

11.46

|

25.27

|

38.48

|

Specification

|

item

|

value

|

|

Type of Scaffolding

|

Kwikstage System Scaffolding

|

|

Warranty

|

3 years

|

|

Standard

|

AS/NZS 1576, AS 1577, BS1139

|

|

After-sale Service

|

Online technical support

|

|

Project Solution Capability

|

graphic design, 3D model design, total solution for projects

|

|

Application

|

industrial scaffolding project

|

|

Design Style

|

Traditional

|

|

Place of Origin

|

Guangdong, China

|

|

Model Number

|

KS.

|

|

Brand Name

|

SHUANGMA

|

|

Material

|

Q235/Q355 Steel

|

|

Tube

|

Vertical Ø48x4.0mm, Ledger Ø48x3.25mm, Brace Ø48x2.5/2.3mm

|

|

Length

|

0.5m-3.0m

|

|

Type of Welding

|

CO2 Protected welding

|

|

Surface Treatment

|

hot dip galvanized, painted, powder coated

|

|

Packing

|

Steel Pallets

|

Manufacturing Technique

Material and Cutting Workshop

All materials, include CHS/RHS/SHS tubes, plate, PFC , angle steel, etc, will be inspected when entering into warehouse.

Automatic Cutting Machine

The maching can cuts tubes, PFC, angle steel in bundle, and cut the materials into the set length automatically.

Automatic Hole-Punching Machine

This machine is specially designed for hole-punching. It is controlled by computer and can be automtic feed and punching.

Steel Plank Production Line

The production line is specially fabricated steel planks in 240mm wide. It automatically do plank forming, punching and cutting process.

Automatic Welding Machine

This machine is specially designed for ring lock scafold vertical welding. It can weld 6 rossettes at the same time with high efficiency and high welding quality. Also ledger welding machine can do round welding for other scaffold items, such as steel props.

Powder Coating Production Line

The production line do good coating job for scaffold items. Before coating, we do sandblasting firstly to clean the steel surface so that the powder can be well electrostatic adherence.

Quality Assurance

We take many efficient measurements to ensure our scaffolding in good quality.

Material Inspection

When materials enter into warehouse, inspection for sizes, surface, mill certificate must be checked.

Material Test

Further flattening test/flaring test shall be done when there is special requirements for the products.

Welding Penetration Test

This test is to check if the welds of ring lock scaffold and assure the safety work when in construction.

Zinc Slag Cleaning

Clean the Zinc slag of tube inside for sure the screw jack can be inserted the vertical freely.

Thickness Gauge

To check the thickness of powder coat or hot dip galvanization, ensure the scaffolds are in good coating protection.

Third Party Inspection

Third party inspection is the last inspection for scaffolding before they are shipped out.

Hot Searches