- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

without motor

-

Dimension(L*W*H):

-

standard

-

Weight:

-

11 KG

-

After-sales Service Provided:

-

Video technical support

-

Color:

-

Customers' Requirements

-

Certification:

-

ISO9001:2008 CE

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huahong

-

Voltage:

-

without motor

-

Dimension(L*W*H):

-

standard

-

Weight:

-

11 KG

-

After-sales Service Provided:

-

Video technical support

-

Color:

-

Customers' Requirements

-

Certification:

-

ISO9001:2008 CE

1,gold mercury amalgam retort , Mercury Distill, Gold mercury amalgamation machine

Gold purify amalgamator is widely used in small gold mining plant for evaporation the Hg from the Hg+ gold mixture, and refining the pure gold.

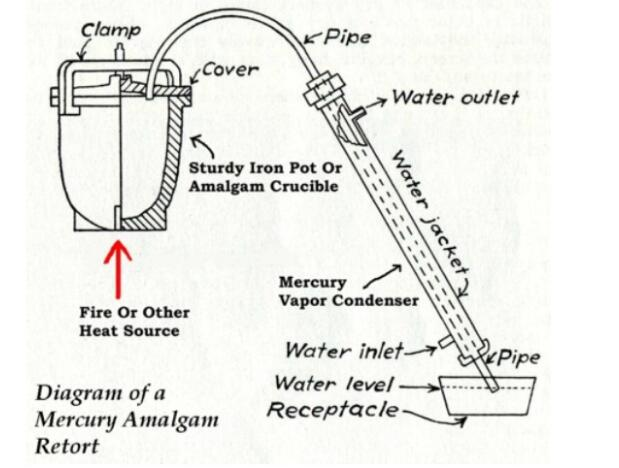

2,gold mercury amalgam retort Working principle

Due to mercury gasification temperature is below the melting point and boiling point of gold. We commonly used the method of distillation to separate the gold from amalgam mercury.

3,gold mercury amalgam retort Operating instruction

1. Put the amalgam mercury with gold into the sealed mercury distill

There is a condenser tube connected with the top of the distiller.

2. Heat the distiller on the coke, gas or electric furnace

3. When the temperature reached 356°C, the amalgam will gasification, the mercury gas will run out through the iron tube

4. The gas mercury will become Spherical droplets after go through the condenser tube, and then you can recycle the mercury.

5. In order to separate the Hg completely, gold mining plant usually maintained the temperature on 400-450°C. And in the last 30 minutes, raised the temperature to 750-800°C.

6. Distill the mercury for around 5-6hours, the gold recovery rate can reach 99%.

4,gold refining amalgamator advantages:

1. low price, fast pay back

2. small, very easy to carry and remove

3. high efficient, easy operation

4. Hg recycle use

plastic gold pan machine

Wet pan mill

Welcome to visit our factory anytime!!!