- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3550*1370*4200mm

-

Power (kW):

-

36.5kw

-

Weight (KG):

-

5000 kg

-

Name:

-

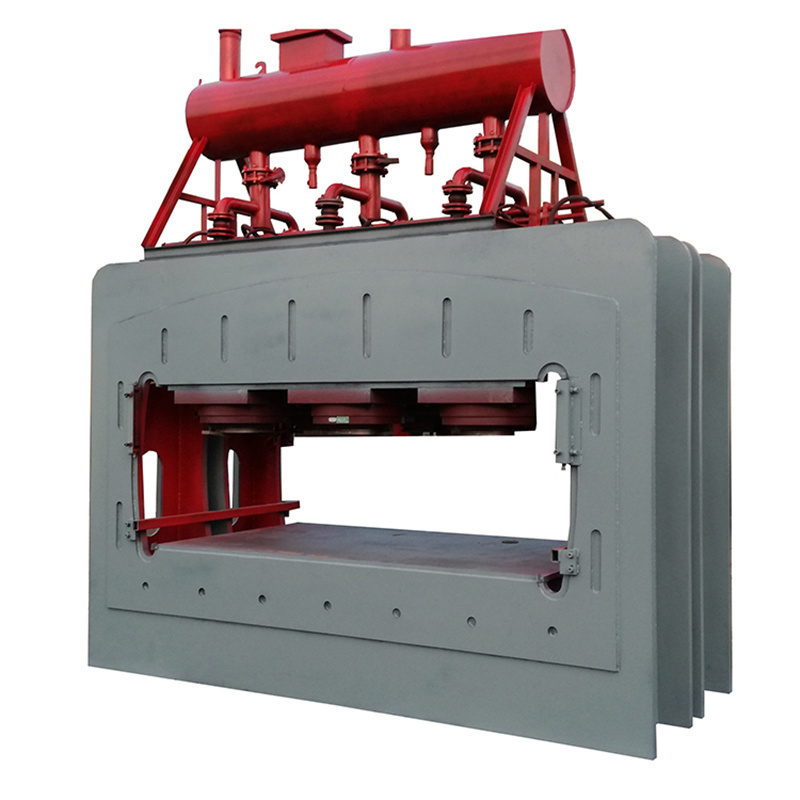

Laminate wood flooring melamine press machine

-

Nominal pressure:

-

12000kn

-

Hydraulic cylinder dia.:

-

320mm

-

Cylinder stoke:

-

200mm

-

Hydraulic working pressure:

-

25mpa

-

Heat platen layers:

-

2

-

Opening quantity:

-

1

-

Opening height:

-

200mm

-

Heat platen size:

-

2700*1350mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RUIFENG

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3550*1370*4200mm

-

Power (kW):

-

36.5kw

-

Weight (KG):

-

5000 kg

-

Name:

-

Laminate wood flooring melamine press machine

-

Nominal pressure:

-

12000kn

-

Hydraulic cylinder dia.:

-

320mm

-

Cylinder stoke:

-

200mm

-

Hydraulic working pressure:

-

25mpa

-

Heat platen layers:

-

2

-

Opening quantity:

-

1

-

Opening height:

-

200mm

-

Heat platen size:

-

2700*1350mm

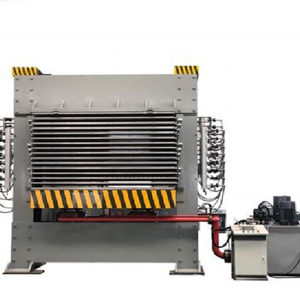

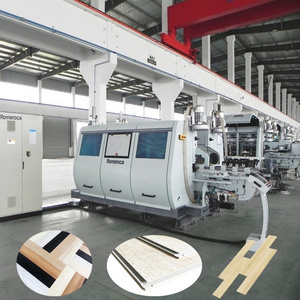

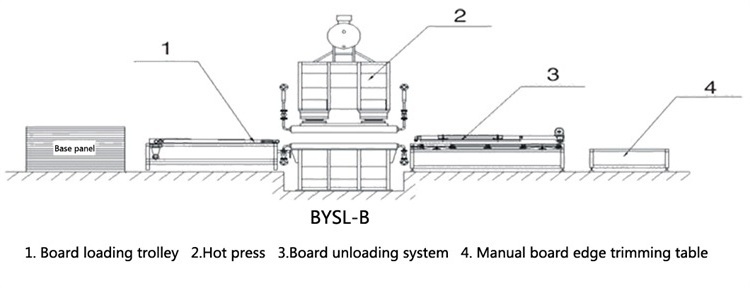

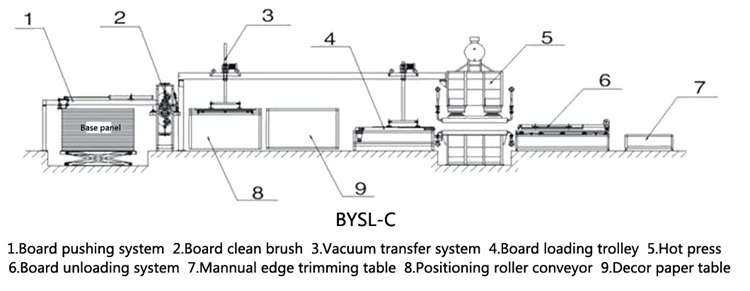

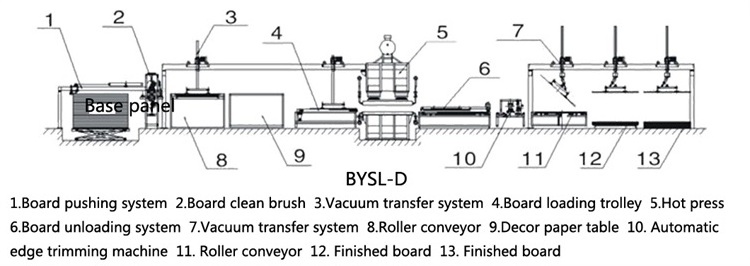

We are engaged in offering our clients with a qualitative range of Short Cycle Laminating Press/ Pre-lamination Hot Press. These are also called as melamine line and are used for producing lamination boards (pre-lam). Our range comprises units used for board feeding (sandwich structure loading), laminating press body, and unloading unit with board inspection, cooling, sorting and stacking. These are available in 4’x8’, 4’x9’, 5’x10’, 6’x9’, and 6’x12’ 7’ x 14’ and larger models. Our range is ideal for lamination of melamine impregnated paper onto particle boards, MDF boards, or HDF boards. Moreover, the melamine faced composites are used extensively for home and office furniture. Some common applications of the boards are furniture board, structure mould board, flooring and mold door skin.

| Type |

Size

(ft) |

Nominal Pressure

(KN) |

End Panel Size

(mm) |

Working pressure

(kg/cm2) |

Main oil cylinder (Diameter×Quantity) |

| BY6648-900T | 4×8 | 9000 | 1220×2440 | ≤30 | Φ280×6 |

| BY6648-1200T | 4×8 | 12000 | 1220×2440 | ≤40 | Φ320×6 |

| BY6668-1400T | 4×8 | 14000 | 1220×2440 | ≤47 | Φ340×6 |

| 5×8 | 1550×2440 | ≤37 | Φ340×6 | ||

| 6×8 | 1830×2440 | ≤31 | Φ340×6 | ||

| BY6679-1600T | 4×8 | 16000 | 1200×2440 | ≤53 | Φ380×6 |

| 4×9 | 1200×2750 | ≤47 | Φ380×6 | ||

| 5×8 | 1500×2440 | ≤42 | Φ380×6 | ||

| 7×9 | 2100×2750 | ≤27 | Φ380×6 |

Characteristics

1.Scientific design of cylinder structure and sealing form, completely prevent the cylinder oil leak case

2.Frame plate produced by the whole steel plate, three sets of frame plate and press sill processing together, ensure the installation precision of the press, and can effectively reduce caused by machining size inconsistent deformation in the process of pressurized hot press plate.

3.In the hot platen and the other does not require heating parts with compression of the installation position of insulation board, which can effectively reduce heat loss and lower ambient temperature.

4.The open and close of compressor used high-precision imported proportional valve, has to slow down, in the process of up and down in to speed up the press to open the closed at the same time, reduce the vibration and impact.

5.The bore diameter and increases the high pressure accumulator charging valve, to shorten the pressure time and ascension, and even the motor work time, effectively reduce the pressure power consumption. The main hydraulic components adopt foreign top brands, stability and reliability of the system improved; Hydraulic system with large area of water or air cooled chiller, greatly reduces the run-time temperature of hydraulic oil.

Our service

Presale service

1. Make reliable pratical mechine list and production proposal free of charge, according to customers' actual situation

2. Design the machine free of charge, according to customer's production line and production cost,

3. Make the workshop and production line layout free of charge, according to customers' factory land

Medium-sales service

1. Video for the manufacturing process as customers requirement

2. Machine modifying according customers' suggestion

3. Order the shipment and prepare the documents for customers' clearance, according to customers' custom requirement

After-sale services

1. One year warranty for main machine, cost price for vunerable parts

2. Experienced engineer is avaiable for the machine installation and worker training

3. Cooperate with Aliyun OS, remote control of trouble shoting and system upgrading

Engineers available to service aboard short cycle laminating hot press

Melamine cover board making machine hot press machine