- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

C-1280D-365-192

-

Voltage:

-

High Pressue

-

Dimension(L*W*H):

-

According to actual size

-

Weight:

-

67000 KG

-

Features:

-

Conventional Walking-beam

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Crank Pin Bearing::

-

22310,22317

-

Voltage::

-

380V

-

Pressure::

-

High Pressue/ Low Pressure

-

Certification::

-

API spec 11E,

-

Strole Lengths::

-

20,24,28,30,36,37,40,48,54

-

Warranty::

-

20 months

-

Weight::

-

5T-50tT,5T-50T

-

Dimension(L*W*H)::

-

2.5x2.5x5

-

Use::

-

Oil field equipment

Quick Details

-

Production Capacity:

-

100unit/month

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

sanmon

-

Model Number:

-

C-1280D-365-192

-

Voltage:

-

High Pressue

-

Dimension(L*W*H):

-

According to actual size

-

Weight:

-

67000 KG

-

Features:

-

Conventional Walking-beam

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Crank Pin Bearing::

-

22310,22317

-

Voltage::

-

380V

-

Pressure::

-

High Pressue/ Low Pressure

-

Certification::

-

API spec 11E,

-

Strole Lengths::

-

20,24,28,30,36,37,40,48,54

-

Warranty::

-

20 months

-

Weight::

-

5T-50tT,5T-50T

-

Dimension(L*W*H)::

-

2.5x2.5x5

-

Use::

-

Oil field equipment

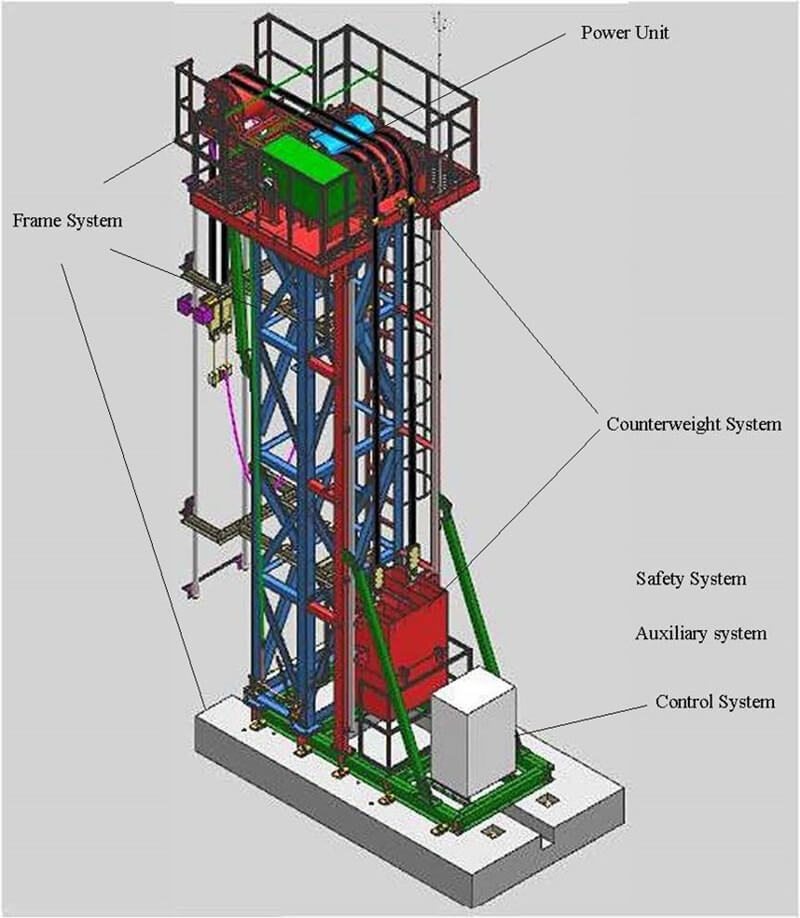

API BELT TOWER PUMPING UNIT

Belt tower pumping unit is specially designed to solve the inherent defects of beam pumping unit.

It has the advantages of energy-saving, convenient parameter adjustment and long stroke

* Beam pumping unit is the most widely used mechanical equipment in oil field, but it has many inherent defects. Such as high energy consumption, low mechanical efficiency, not easy to achieve a long stroke.

* Non-beam pumping unit is developed to solve the inherent defects of beam pumping unit. It is characterized by high degree of automation, intelligent parameter adjustment, low energy consumption and low noise.

1. Main Structure:

1) Frame System

It is composed of an upper platform, a main frame, front and rear supports, a large base, and a cement foundation composed of a steel structure.Support the upper platform to ensure the maximum stroke of the smooth sucker rod.

2)Power Unit

Installed on the upper platform, including: motor, driving wheels, guide wheels, couplings, reducers, automatic brakes, manual brakes, etc., are the executive parts of the pumping unit to transmit torque.

3) Counterweight System

It is composed of counterweight box (main and auxiliary), slide rail and pulley block.

Precisely adjust the weight of the counterweight box and the balance of the oil sucker polished rod end to make the machine run smoothly and save energy.

4) Control System

It is mainly composed of motor, SR controller, programmable logic controller (PLC), and various operation buttons.It is a stepless speed regulation system, which can realize the automatic and manual control modes and fault display of the equipment.

5) Safety System

It is composed of upper and lower (double) limit switches, proximity switches, automatic (manual) brake devices, lightning arresters, and counterweight box buffer pits. Ensure the safe operation of equipment.

6) Auxiliary system

Load sensor, liquid level detector, monitoring, acquisition system, etc.

7)Security system

Multiple Security Protection Automatic alarm and brake for overload, overspeed and lack of phase.

Loss of Load Protection Sudden rod breakage and other faults cause loss of load, and there is brake protection.

2.Features of the tower type belt driven pumping unit

1) 30% ~ 50% power saving, small torque arm, accurate balance of counterweight

2) The stroke length is 1 ~ 10 meters, and the data of stroke and stroke times are displayed online

3) Good working condition, stable operation, small impact, low noise 70dB.

4) Multiple safety protection: complete protection measures for phase loss, overspeed and loss of load.

5) Touch the display to adjust stroke and stroke times.

6) Automatic fault alarm display.

7) The motor power factor is 0.993.

8) Equipped with 485 and 232 communication interfaces to support centralized control of multiple machines.

9) The whole machine and electric control cabinet are equipped with lightning protection devices.

10) Equipped with load sensor and online work drawing collection function.

3.Support centralized control to realize automatic oil production in cluster wells

|

Model

|

Rated polished rod load (lbs)

|

Stroke length (in)

|

Rated torque of reducer (in.lbs)

|

|

C-912D-470-240

|

47,000

|

240, 211, 181

|

912,000

|

|

C-912D-427-216

|

42,700

|

216, 185, 155

|

912,000

|

|

C-912D-427-192

|

42,700

|

192, 165, 138

|

912,000

|

|

C-912D-305-192

|

30,500

|

192, 165, 138

|

912,000

|

|

C-912D-365-168

|

36,500

|

168, 144, 121

|

912,000

|

|

C-912D-305-168

|

30,500

|

168, 144, 121

|

912,000

|

|

C-912D-427-144

|

42,700

|

144, 123, 102

|

912,000

|

|

C-640D-305-192

|

30,500

|

192, 165, 138

|

640,000

|

|

C-640D-305-168

|

30,500

|

168, 144, 121

|

640,000

|

|

C-640D-365-144

|

36,500

|

144, 123, 102

|

640,000

|

|

C-640D-305-144

|

30,500

|

144, 123, 102

|

640,000

|

|

C-640D-256-144

|

25,600

|

144, 123, 102

|

640,000

|

|

C-640D-305-120

|

30,500

|

120, 102, 84

|

640,000

|

|

C-456D-305-168

|

30,500

|

168, 144, 121

|

456,000

|

|

C-456D-305-144

|

30,500

|

144, 123, 102

|

456,000

|