1. More than 90% parts completely independent processing, effectively guarantee the processing precision

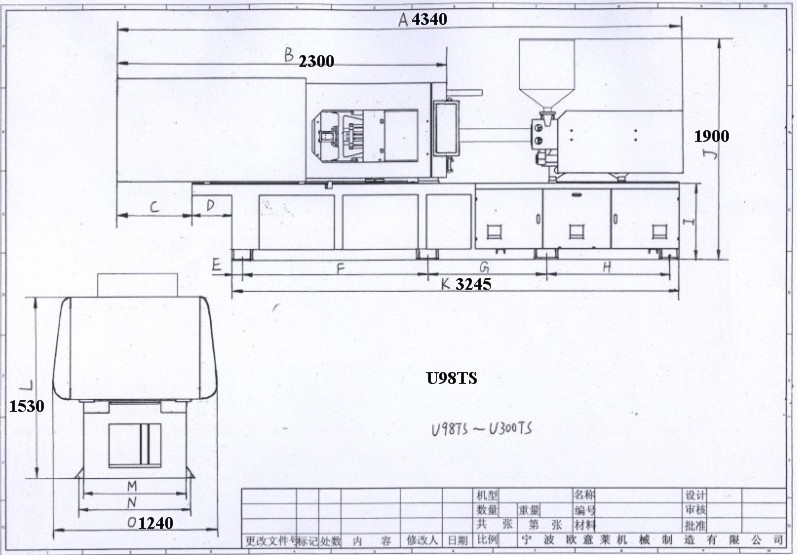

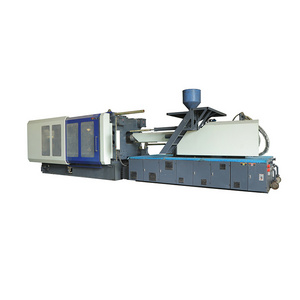

2. Large-scale machining center, gantry milling and other equipment to make us fully capable of processing 3400 tons of the following equipment

3. ISO9001 quality management system certification, quality for the enterprise to build on a new level

4. Strict inspection division of labor, make the production each link control