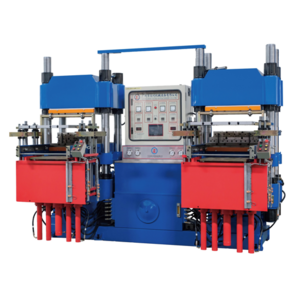

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

6800

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product name:

-

Oil seal vulcanizing machine

-

motor:

-

good

-

PLC:

-

omron

-

Name:

-

curing press with Oil seal

-

Color:

-

Custom Made

-

Certificates:

-

CE;ISO

-

Power:

-

5.5KW

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

chaoguangyue

-

Voltage:

-

380V/220V

-

Weight:

-

6800

-

Power (kW):

-

5.5

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product name:

-

Oil seal vulcanizing machine

-

motor:

-

good

-

PLC:

-

omron

-

Name:

-

curing press with Oil seal

-

Color:

-

Custom Made

-

Certificates:

-

CE;ISO

-

Power:

-

5.5KW

-

Marketing Type:

-

Ordinary Product

Rubber Vulcanizing machine/Hydraulic press/EVA Vulcanizing machine

We have ISO9001:2008,SGS,CE standard and offer all kinds of certification according to customer's request:like CO,CIQ,SASO and so oxn.

1. Material of steel plate:

We use hight quality carbon steel Q-235(produce by Jigang Group Co.,Ltd which is a famous company) ,more thicker than other supplier,after shot blasting ,smooth, it is strong enough than common steel

2. Weldment of frame : world technique

Welded together as a whole part,Stewing fire treatment after weldment.

(Carbon dioxide gas shielded welding,alloyed welding wire).

submerged arc welding, VSR treatment after weldment.

3.Piston:

the material of plunger is Chilled cast iron, after polishing,grinding treatment and resist compression test,make the surface smooth,anti-abrasion,durable.

4. Heating way&precision temperature control:

Steam ,oil or Electric (We use high quality hot platen and heating pipe to keep heating stability and uniformity)

range of temperature:0-300 °C (can be adjustment if you need 400 °C ,we can do it )

Plate temperature tolerance: ±0.1°C (very precise)other factory just is ±3°C

Also we can produce the machine with water cooling system.

♥ 5. Hydraulic system: (PLC control)

the professional hydraulic components, stable and reliable and quality .Pressure sensor control system pressure and never off pressure.

We use OMRON,SIMENS CHNT , SCHNEIDER ect brand electric parts.

6.There are more advanced technical information as our core patents ,and not showed in the description,please send email to us.

|

Parameters/version

|

XLB350*350*2 |

XLB400*400*2 |

XLB500*500*2 |

XLB600*600*2/4 |

XLB750*850*2 |

XLB1000*1000*2 |

|

Mould closing force |

0.25 |

0.5 |

0.8 |

1.0 |

1.6 |

2.5 |

|

Hot plate spacing |

125 |

125 |

125 |

125 |

125 |

200 |

|

Hot plate layer |

2 |

2 |

2 |

2/4 |

2 |

2 |

|

Plunger stroke |

250 |

250 |

250 |

250/500 |

250 |

400 |

|

Heating way |

Electricity/stream |

Electricity/stream |

Electricity/stream |

Electricity/stream |

Electricity/Stream |

Electricity/stream |

|

Main motor power |

2.2 |

2.2 |

2.2 |

2.2 |

3 |

5.5 |

|

The thermal power |

2.4kw/board |

3kw/board |

3 |

7.5kw/board |

9kw/board |

10.8kw/board |

|

Size(l*w*h) |

1450*400*1350 |

1600*400*1440 |

1450*690*1818 |

1880*780*1660 |

2100*1010*1900 |

2400*960*2500 |

|

Weight(kg) |

1200 |

1500 |

|

|

|

|

Exibition & Customers

All the product are CE,ISO,SGS Approved.

Packaging Details: Wood Pallet & Film Wrap

Delivery Detail: 60 Working Days Since Down Payment

1.

pre-sale services

Act as a good adviser and assistant of client enable them to get rich and generous returns on their investments.

1)select equipment model

2)design and manufacture products according to clients' special request

3)train technical personnel for clents.

2.services during the sale

1)Recheck and accept products ahead of delivery

2)Help clients to draft solving plans

3.after-sale services

1)provide considerate services to minimize client's worries.

2)Help client to solve the assembly question

3)take responsibility if any technical problem