Qingdao Fullwin Plastic Machinery Co., Ltd. is a manufacturer specializing in plastic extrusion machine and auxiliaries, including single-wall corrugated pipe production lines, double-wall corrugated pipe production lines, PVC/PP water supply pipe production lines, profile and sheet production lines, etc.

Fullwin corrugated pipe production line has won a number of invention patents, and the company also has various certifications such as CE, ISO, etc.

Fullwin machinery product exported to countries all over the world, such as Germany, Switzerland, the Middle East, Southeast Asia, South America, Africa and other countries.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

11

-

Weight:

-

700 KG

-

extruder model:

-

SJ75

-

Raw material:

-

PE EPE

-

Usage:

-

Fruit package

-

Product:

-

plastic net

-

Automatic Grade:

-

fully automatic

-

Inverter:

-

ABB Brand

-

Motor:

-

Siemens Beide

-

Temperature control:

-

Omron Brand

-

Cooling way:

-

Water Cooling+Air Cooling

-

Plastic Machine:

-

fruit bag foam net machine

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fullwin

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

11

-

Weight:

-

700 KG

-

extruder model:

-

SJ75

-

Raw material:

-

PE EPE

-

Usage:

-

Fruit package

-

Product:

-

plastic net

-

Automatic Grade:

-

fully automatic

-

Inverter:

-

ABB Brand

-

Motor:

-

Siemens Beide

-

Temperature control:

-

Omron Brand

-

Cooling way:

-

Water Cooling+Air Cooling

-

Plastic Machine:

-

fruit bag foam net machine

Product Overview

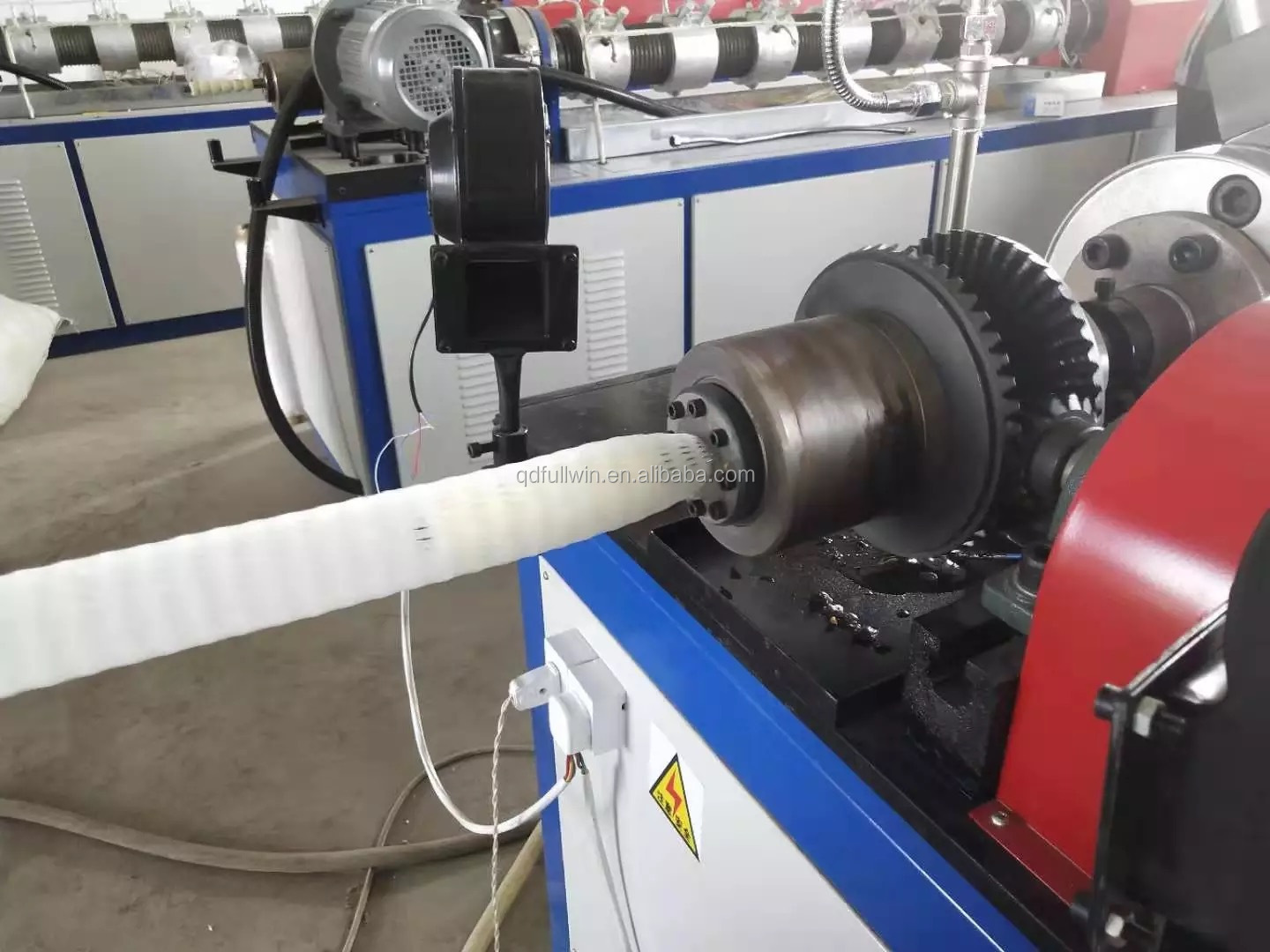

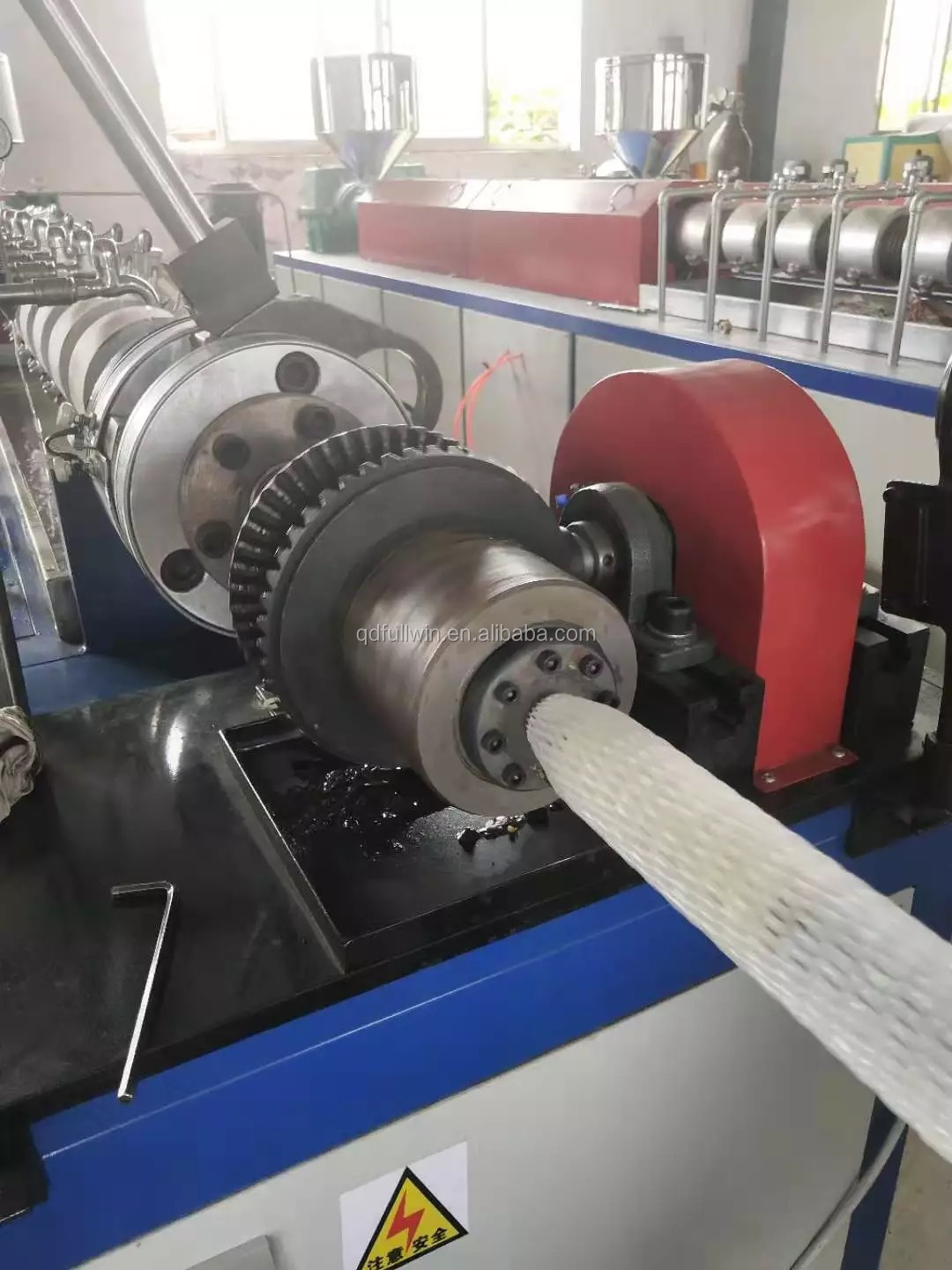

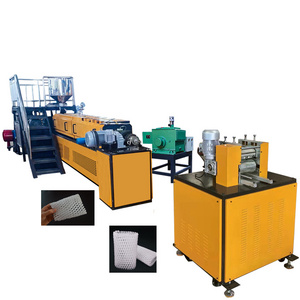

EPE Foam Fruit Net Plastic Extruder Machine

EPE foam machines apply for the production of EPE foam materials. After thawing the LDPE resin mixed with butane gas, talcum powder, anti-shrink agent and other agents. With different mold heads, the extruder can foam and form various shapes of products, such as sheet, tube, rod, angle profiles (L or U), round and batten. Then use the different ancillary equipment to roll, cut, laminate or coating.

|

model

|

L*W*H (m)

|

Weight

(ton) |

Screw Diameter

|

Total Power

|

Foaming Ratio

|

Output Capacity kg/h

|

Products' Width mm

|

Products' Thickness mm

|

|

EPE-75

|

20*4*3

|

3

|

75

|

55

|

30-40

|

25-50

|

1600

|

0.3-3 |

|

EPE-90

|

22*4*3

|

7.5

|

90

|

75

|

30-40

|

60-90

|

1600-2000

|

0.3-5

|

|

EPE-105

|

25*4*3

|

8.5

|

105

|

95

|

30-40

|

80-120

|

1600-2500

|

0.3-6

|

|

EPE-120

|

27*4*3

|

9.5

|

120

|

115

|

30-40

|

120-180

|

1600-3000

|

0.5-8

|

|

EPE-135

|

35*4*3

|

10.5

|

135

|

150

|

30-40

|

170-240

|

1600-3000

|

1-10

|

|

EPE-150

|

38*7*3

|

11

|

150

|

220

|

30-40

|

250-300

|

1600-3000

|

2-12

|

|

EPE-180

|

41*7*3

|

11

|

180

|

330

|

30-40

|

300-400

|

1600-3000

|

2-12

|

|

EPE-200

|

42*7*3

|

15

|

200

|

400

|

30-40

|

350-500

|

1600-3000

|

3-18 |

|

EPE-220

|

45*7*3

|

18

|

220

|

320

|

30-40

|

400-600

|

1600-4000

|

3-20 |

|

EPE-250

|

50*7*3

|

23

|

250

|

330

|

30-40

|

500-800

|

1600-4000

|

4-20

|

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

FAQ

Q1:

why choose us?

Excellent domestic and foreign trade team will bring you worry-free after-sales service.

A1:More than 20 years of experience in the machinery industry,

specialized technology and R & D team tailored for you.

Excellent domestic and foreign trade team will bring you worry-free after-sales service.

Q2:what service will be offered to buyers?

A2:Pre sales communication to design , drawing confirmation to customized prouction to test machine before shipment to package and delivery to engineer installation to training workers to technical support

Q3:Payment of terms

A3:30% should be paid as down payment, 70% paid before shipment by TT or L/C at sight

Q4:DELIVERY CONDITIONS

A4:delivery port: QINGDAO DAO

After sales service

- After all machines are delivered to customer’s factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer’s factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer’s factory.

- If buyer doesn’t request installation and commissioning by Seller’s engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

OUR TEAM

Customer Photos

Recommend Products

New design normal speed single wall corrugated pipe machine

diameter:4mm-200mm

line speed:8-15m/min

air and water cooling both

High speed single wall corrugated pipe machine

9-12mm one machine design

14-50mm one machine design

16-63mm one machine design

induct germany design

line speed 225-30meters /min

extension/magic pipe machine

air conditioner usage

washing machine usage

Double wall corrugated pipe machine

40-160mm for air ventilation system

Double wall corrugated pipe machine 200-800mm

100-500mm

200-800mm

for water drainage usage

pp/pe/ppr/pvc solid pipe machine

16-63mm

75-160mm

110-315mm

315-500mm

400-800mm

WPC/PVC Door &Frame profile machine

HDPE/PP Big diameter winding sewage pipe machine

PVC fiber reinforce hose machine

pvc steel wire hose machine

HDPE Hollow wall winding machine

PVC/ASA Roofing wave tile /bamboo tile machine

Contact us

|

Contact

|

Lisa LEE

|

|

Cell Phone

|

+86 18563916721

|

|

Wechat

|

+86 18563916721

|

|

Email

|

sales1@qdfullwin.com

|

|

|

sales1@fullwinmachinery.com

|

|

website

|

www.fullwinmachinery.com

|

Hot Searches