- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Defined by model

-

Warranty:

-

1 YEAR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

coal dust,charcoal dust,fine powder,iron power

-

color:

-

As your requirements

-

Application:

-

Coal, charcoal, mineral powder, metal powder etc

-

install:

-

under engineer guidance

-

Briquette shape:

-

Round,Square,Pillowor as your requirement

-

Pressure:

-

machinery, hydraulic,spiral

-

Working Theory:

-

Roller Press

-

OEM service:

-

offer, sawdust briquette press machine

-

Quality:

-

good,sawdust briquette press machine

-

Certification:

-

ISO9001,CE, GOST

Quick Details

-

Production Capacity:

-

1-30 t/h

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

YUKE briquetting equipment

-

Dimension(L*W*H):

-

Defined by model

-

Warranty:

-

1 YEAR

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

coal dust,charcoal dust,fine powder,iron power

-

color:

-

As your requirements

-

Application:

-

Coal, charcoal, mineral powder, metal powder etc

-

install:

-

under engineer guidance

-

Briquette shape:

-

Round,Square,Pillowor as your requirement

-

Pressure:

-

machinery, hydraulic,spiral

-

Working Theory:

-

Roller Press

-

OEM service:

-

offer, sawdust briquette press machine

-

Quality:

-

good,sawdust briquette press machine

-

Certification:

-

ISO9001,CE, GOST

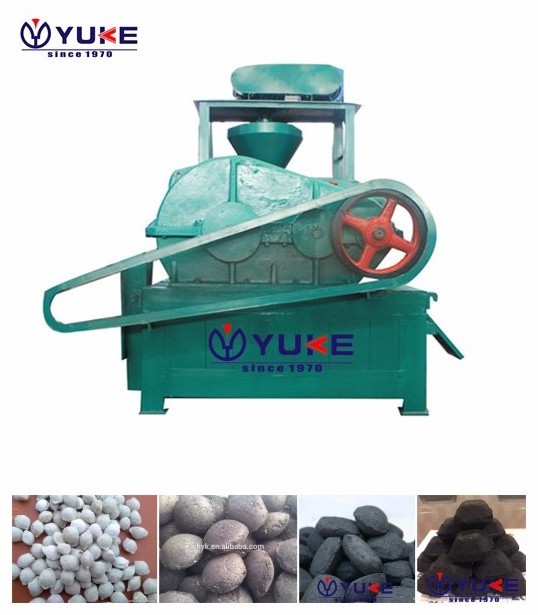

YUKE Hydraulic briquetting machine

is equipped with hydraulic system which makes it different from common briquette machine.Thanks to the hydraulic device,the pressure for compressing raw materials can keep constant.In addition,when bigger or harder materials enter into rollers,the hydraulic system will work to project the roller and ensure higher briquetting efficiency.

Fly ash hydraulic dry powder briquette machine

is used for making lime powder ferrosilicon powder chromium powder,refractory materials and other different powders which contain low content water or no water.

The hydraulic briquette machinery is widely used in various industries,including metallurgy,chemical,refractory

materials,energy,transportation and heat supply industry,etc.for compressing all kinds of mineral powders and chemical powders.To be specific,this hydraulic briquette making machine has been highly recognized by some enterprises such as briquette plant,steel plant,power plant,chemical plant,cement plant,etc.The hydraulic briquetting machine can form materials into wide variety of shapes,and specifically shaped briquette can be customized if required.

The hydraulic briquette machinery is widely used in various industries,including metallurgy,chemical,refractory

materials,energy,transportation and heat supply industry,etc.for compressing all kinds of mineral powders and chemical powders.To be specific,this hydraulic briquette making machine has been highly recognized by some enterprises such as briquette plant,steel plant,power plant,chemical plant,cement plant,etc.The hydraulic briquetting machine can form materials into wide variety of shapes,and specifically shaped briquette can be customized if required.

|

Model

|

YKHD530

|

YKHD650

|

YKHD750

|

YKHD850

|

|||

|

Diameter(mm)

|

530

|

650

|

750

|

850

|

|||

|

Width(mm)

|

196

|

196

250

|

196

250

|

196

250

|

|||

|

Max Lineal Presure Ratio(t/cm)

|

5

|

6

|

6

|

8

|

|||

|

Total pressure(t)

|

100

|

110

|

120

|

300

|

|||

|

Power(kw)

|

45

|

55

75

|

75

90

|

90

110

|

|||

|

Precompressed power(kw)

|

11

|

15

|

18.5

|

18.5

|

|||

|

Power of the oil pump(kw)

|

1.5

|

1.5

|

2.2

|

3

|

|||

|

Speed(r/min)

|

9

|

9

|

9

|

9

|

|||

|

Capacity(t/h)

|

2-4

|

5-8

|

8-12

|

9-15

|

|||

|

Size of the ball(mm)

|

38*25*13(Customize)

|

|

|

|

|||

Working Principle

YUKE briquetting machine consists of three parts,namely feeding part,drive part and briquette molding part (main body)

Feeding Part

The feeding part is mainly used to achieve ration feeding so as to ensure that the materials can be fed into the rollers

uniformly.Specifically,the screw feeder,driven by electromagnetic speed adjustable motor,presses materials into the main feeding port compulsively by means of the belt pulley and worm reducer.Owing to constant torque,the motor can keep constant feeding pressure,ensuring stable briquette quality.

Drive Part

The main drive system of the briquetting machine is composed of motor,triangle belt,reducer,exposed gear and rollers.The power generated by the electromagnetic speed-adjustable motor transmits to the driving shaft through belt pulley,reducer and coupler,and the driving shaft will turn synchronously with the driven shaft by the exposed gear.

Briquette Molding Part

The core of the briquette molding part is the rollers.Through rollers,the raw materials can be compressed into briquettes with various shapes.In addition, the rollers feature overload protection,hence keeping sound quality.

The feeding part is mainly used to achieve ration feeding so as to ensure that the materials can be fed into the rollers

uniformly.Specifically,the screw feeder,driven by electromagnetic speed adjustable motor,presses materials into the main feeding port compulsively by means of the belt pulley and worm reducer.Owing to constant torque,the motor can keep constant feeding pressure,ensuring stable briquette quality.

Drive Part

The main drive system of the briquetting machine is composed of motor,triangle belt,reducer,exposed gear and rollers.The power generated by the electromagnetic speed-adjustable motor transmits to the driving shaft through belt pulley,reducer and coupler,and the driving shaft will turn synchronously with the driven shaft by the exposed gear.

Briquette Molding Part

The core of the briquette molding part is the rollers.Through rollers,the raw materials can be compressed into briquettes with various shapes.In addition, the rollers feature overload protection,hence keeping sound quality.

Product Details

Our Advantages

1.Our regular products can be customized in various colors, Customize products according to customer needs.

2.We provide one-year warranty and lifetime service for customers.

3. Accept third-party inspection service to guarantee quality and quantity for you.

4. We provide life-long preservation of customer information and provide spare parts service for life.

5. We provide free technical solutions and technical support. The products are directly supplied by the factory, first-hand source.

6.Our company has been established for a long time and is strong. It is trustworthy to establish cooperative relations with many universities and colleges.

Certifications

1. who are we?

We are based in Shanghai, China, start from 2013,sell to Central America(20.00%),Domestic Market(14.00%),Southeast Asia(13.00%),Mid East(10.00%),South Asia(8.00%),Africa(8.00%),Eastern Asia(6.00%),South America(6.00%),Eastern Europe(5.00%),Northern Europe(3.00%),North America(3.00%),Oceania(2.00%),Southern Europe(1.00%),Western Europe(1.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

briquetting machine,crusher,rotary dryer,coal briquetting machine,mixer

4. why should you buy from us not from other suppliers?

We are manufacture for hydraulic machines, so we offer you the machine directly and the factory price. Well-equipped facilities for making machines & strict inspection team.Design department and foreign trade department match very good to serve clients.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

We are based in Shanghai, China, start from 2013,sell to Central America(20.00%),Domestic Market(14.00%),Southeast Asia(13.00%),Mid East(10.00%),South Asia(8.00%),Africa(8.00%),Eastern Asia(6.00%),South America(6.00%),Eastern Europe(5.00%),Northern Europe(3.00%),North America(3.00%),Oceania(2.00%),Southern Europe(1.00%),Western Europe(1.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

briquetting machine,crusher,rotary dryer,coal briquetting machine,mixer

4. why should you buy from us not from other suppliers?

We are manufacture for hydraulic machines, so we offer you the machine directly and the factory price. Well-equipped facilities for making machines & strict inspection team.Design department and foreign trade department match very good to serve clients.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Hot Searches