- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tai Gao

-

Model Number:

-

D24.1-D125

-

Material:

-

Cobalt Steel Alloys

-

Application:

-

Drilling Holes

-

Color:

-

Black

-

Packing:

-

Wooden Box

-

Diameter:

-

24.1-125mm

-

Product name:

-

BTA Deep Hole Drilling Head

-

MOQ:

-

1pcs

-

Size:

-

as customer's requirements

Quick Details

-

Type:

-

Indexable Drill Bit

-

Use:

-

Metal Drilling

-

Finish:

-

Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tai Gao

-

Model Number:

-

D24.1-D125

-

Material:

-

Cobalt Steel Alloys

-

Application:

-

Drilling Holes

-

Color:

-

Black

-

Packing:

-

Wooden Box

-

Diameter:

-

24.1-125mm

-

Product name:

-

BTA Deep Hole Drilling Head

-

MOQ:

-

1pcs

-

Size:

-

as customer's requirements

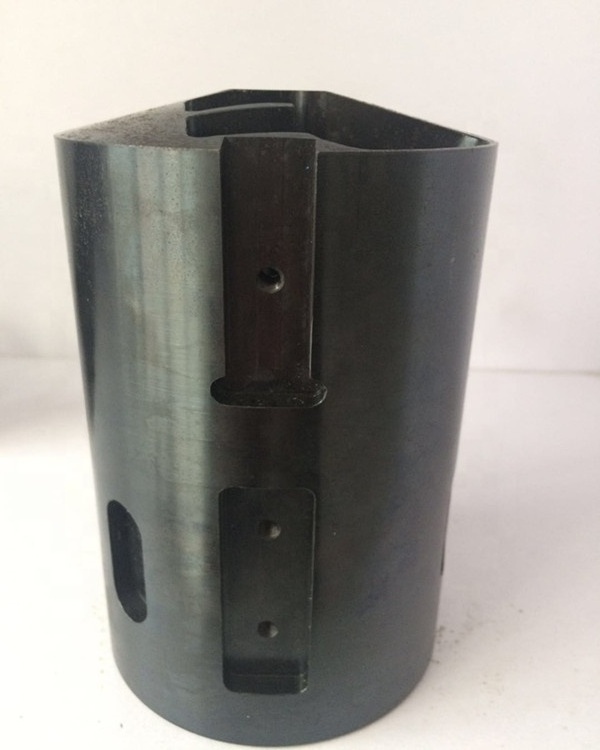

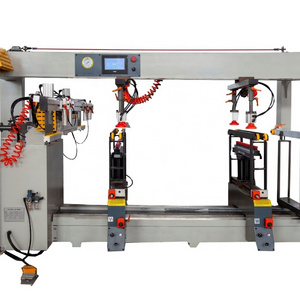

BTA deep hole machine drill with counter boring head type made in China

BTA Drill head :

( diameter range: 24.1-125mm,also can customized as customers needs )

Our deep hole drilling heads are widely used in steel, petroleum machinery, hydraulic equipment, power generation, chemical industry, machine tool, weapon, automobile, ship, coal mine machinery, plastic machinery,aerospace and other industries. With high processing efficiency and good stability, the drilling head have a maximum ratio of length to diameter of more than 300, and their performance reaches the level of similar imported products. After many years of research, development and accumulation, the series of hard-to-machining materials deep hole processing special tools in our company can be used in deep hole processing of special drill steel, stainless steel, non-magnetic stainless steel, high temperature alloy and other materials. They have helped our user to solve a lot of deep hole processing problems, set up a higher brand image, and have got a lot the user's praise.

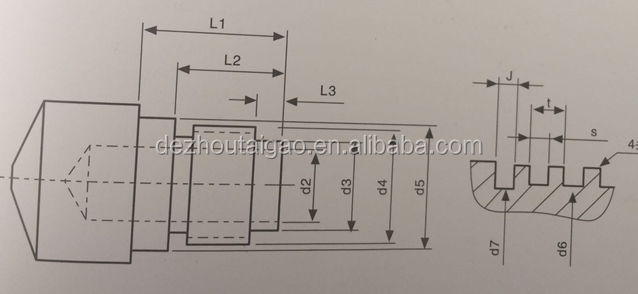

BTA deep hole drill head technical parameter:

Inserts:

Guide Pads:

Drill pipe/Drill tube:

Advantages of BTA deep hole drill head:

The tool body adopts high - strength imported steel material and is heat treated, the service life of the bta drill head is increased by more than 2 times than that of the common drill head. It is made of hard alloy material and the deep hole can be drilled on the solid material such as carbon steel , alloy steel , aluminum , 45 # steel , etc . , the aspect ratio can reach 1 : 100,with the advantages of high processing efficiency , high durability and convenient installation.

Suggession for the choice of coolant for BTA drill head:

1. Oil

oil is the preferred recommendation for the following reasons

Longer tool life. The choice of cutting oil or emulsion is very significant. Usually cutting oil, tool life can be extended by 30%.

Better breaking consistency and wider cutting range

When emulsion is applied, there is a danger of stagnation if the machine tool is used continuously. When the machine tool is idle, the cooling box should be ventilated to prevent the emulsion from becoming inactive

2. Emulsion, as a recommended second option

The application of emulsions is based on the following.

If drilling is done on a production line or on some machine tools with a central system, the application of pure oil becomes more complex

Drilling in a machining center, where most drilling is a subsidiary operation of high-speed machining.

Emulsion can be used to clean parts during reprocessing. If oil is used, the cleaner is sometimes required to remove the oil in the next process or before entering the reservoir.