- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JINUXIN

-

Voltage:

-

as customer needs

-

Dimension(L*W*H):

-

26*3*2m

-

Power (kW):

-

120

-

Weight:

-

8000 KG

-

Raw material:

-

PET & PBT

-

Product Type:

-

human wig filament

-

Extruder:

-

single screw extruder

-

Inverter:

-

ABB

-

Temperature meter:

-

Ormon

-

Contactor:

-

Siemens Contactor

-

plastic filament extruder:

-

plastic huam hair wig monofilament extruder

-

pet/pbt filament extruder:

-

plastic filament extruder

-

human hair wig monofilament material:

-

pet, pp , pbt

-

machine capaicty:

-

30-100kg/h

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

1400 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JINUXIN

-

Voltage:

-

as customer needs

-

Dimension(L*W*H):

-

26*3*2m

-

Power (kW):

-

120

-

Weight:

-

8000 KG

-

Raw material:

-

PET & PBT

-

Product Type:

-

human wig filament

-

Extruder:

-

single screw extruder

-

Inverter:

-

ABB

-

Temperature meter:

-

Ormon

-

Contactor:

-

Siemens Contactor

-

plastic filament extruder:

-

plastic huam hair wig monofilament extruder

-

pet/pbt filament extruder:

-

plastic filament extruder

-

human hair wig monofilament material:

-

pet, pp , pbt

-

machine capaicty:

-

30-100kg/h

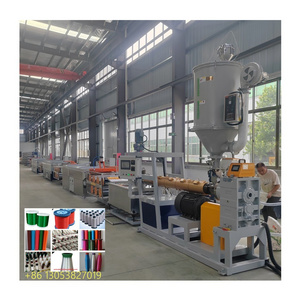

Machine Description

Plastic PP PET

PBT Artificial Huam Hair Wig Monofilament/Yarn/Fiber Extrusion Line

I. Brief Introduction of PP PET PBT Artificial Human Hair Wig Monofilament Extrusion Line

Plastic monofilament extrusion line consists of material loader and dryer,, extruder, material filter, melt pump, mold, haul-off rollers, ovens, and winders

----Raw material: plastic granules

----high tension

----Monofilament diameter: 0.05-1.0mm or as customer needs

Extrusion line picture

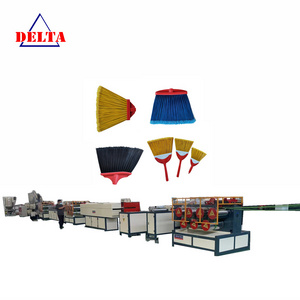

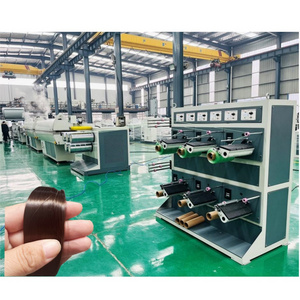

PP PET PBT human hair wig monofilament yarn fiber picture

II. Main Technical Parameters

|

NO

|

Machine Model

|

Machine Capacity

|

Power Consumption

(KW)

|

|

1

|

SJ75

|

60-70kg/h

|

130

|

|

2

|

SJ90

|

150-200kg/h

|

160

|

Machine Pictures & Details

1. S single screw extruder

----optional material drying and loading system for different material

2 . Material Filter, Melt pump, Extrusion Mould & Cooling Tank

--- candle type filter, bigger filtering area, no need change filter net shortly.

----

Close--loop control system

from extruder to melt pump, by which extrusion can be automatically controlled by melt pump.

----Melt pump ensures stable extrusion

----Melt pump ensures stable extrusion

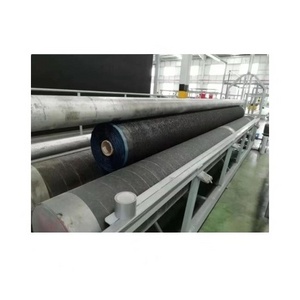

---304 stainless steel water cooling tank

3. Extrusion Mould

---produce different size monofilaments

---hole quantity can be changed

4. Haul-off Rollers

--gear transmission

---chromized rollers

---rollers are PLC synchronized speed control

5. Water Oven

---made by 304 stainless steel

6. Air Oven

---forced air blowing system

---inverter control

---good heat-preservation

7. Winding machine

Winding machine

Machine packaging & Delivery

Hot Searches