Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Yaxiong

-

Model Number:

-

Black Powder Paint

-

Application:

-

Interior Decoration

-

Color:

-

Optional Colors

-

Feature:

-

Eco-friendly

-

Function:

-

Anti-acid

-

Certificate:

-

ISO9001

-

Gloss:

-

Matt\satin\Glossy\High Glossy

-

MOQ:

-

20kg

-

Sample:

-

Availble

-

Payment:

-

T/T, western union, L/C

-

Packing:

-

Plastic Bag, 20kg/carton

Quick Details

-

CAS No.:

-

Standard

-

Other Names:

-

Polyester powder coating

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Yaxiong

-

Model Number:

-

Black Powder Paint

-

Application:

-

Interior Decoration

-

Color:

-

Optional Colors

-

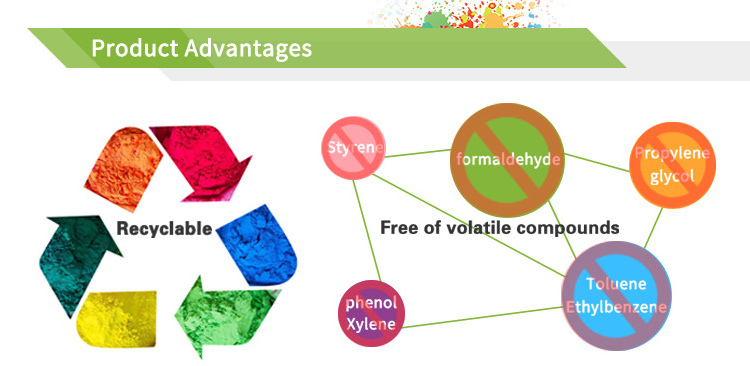

Feature:

-

Eco-friendly

-

Function:

-

Anti-acid

-

Certificate:

-

ISO9001

-

Gloss:

-

Matt\satin\Glossy\High Glossy

-

MOQ:

-

20kg

-

Sample:

-

Availble

-

Payment:

-

T/T, western union, L/C

-

Packing:

-

Plastic Bag, 20kg/carton

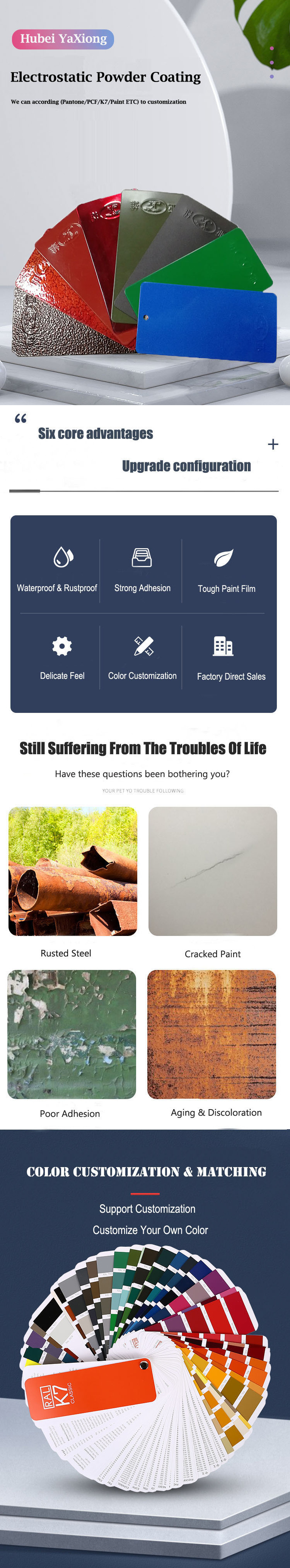

TGIC Electrostatic Rims Blue High Gloss Powder Coating

The colors you see will vary depending on the display, but we will customize the color according to the Ral color card.

TGIC Electrostatic Rims Blue High Gloss Powder Coating

TGIC Electrostatic Rims Blue High Gloss Powder Coating

Brief description:

Mainly made of saturated polyester resin in combination with TGIC curing agent

Features:

1, g ood adhesion, good mechanical properties, tough film, meet high strength requirements

2, smooth film coating and high gloss

3, suitable for long-term outdoor exposure, good outdoor durability

4, excellent resistance to over-baking

Mainly used for:

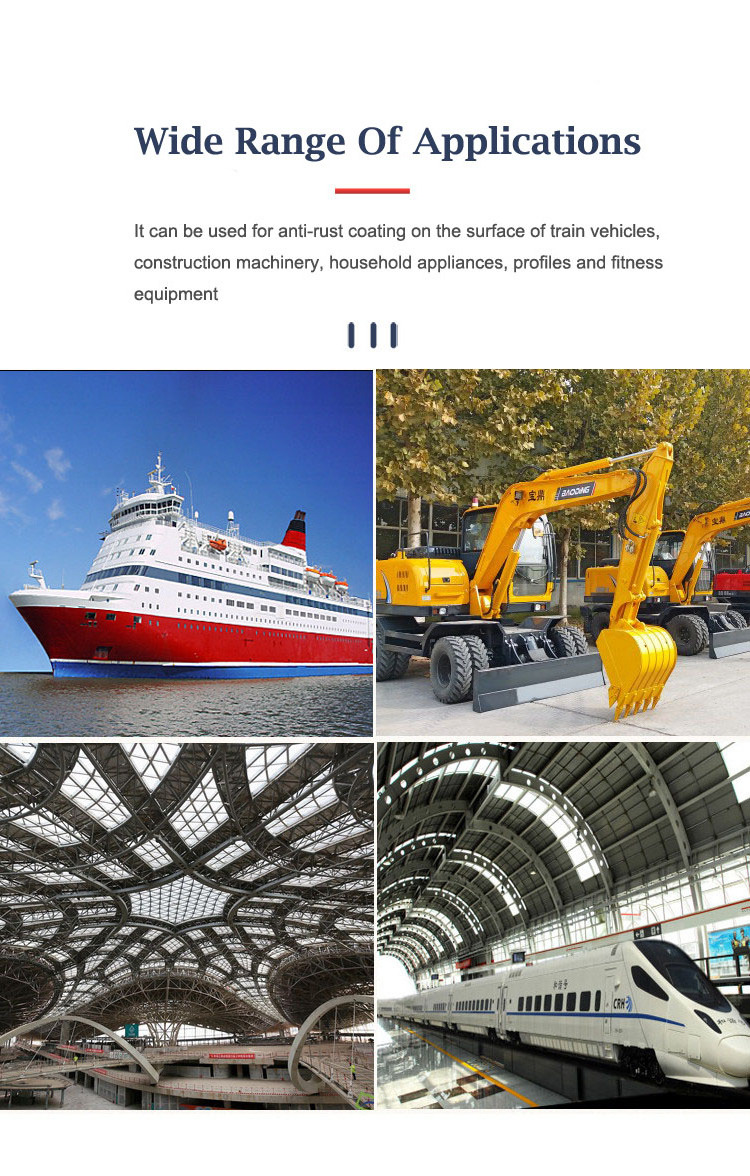

Suitable for all kinds of long-term outdoor exposure products

Household appliances: outdoor units for air conditioners, indoor appliances with high lighting conditions, lamps

Construction applications: colorful curtain walls, door and window frames, high-light conditions

Transportation facilities: highway guardrails, grilles

Auto parts, sports facilities, fitness equipment, gas station equipment, yard facilities

Available in standard and ultra high weather resistant

Can be made into a variety of glossy and colorful colors: A-type highlights (greater than 85%), B-type flat light (50%-85% or less), C-type matte (25%-50%), D-type semi-matte (10 %-25% or less), E-type matte (10% or less). The specific gloss color is subject to the user's designation; it can be made into a variety of fine art texture products such as sand, wrinkles, netting, cotton, hammer, moire, point spread, anti-stone, metal powder, antique copper.

Application condition

Pure Polyester / TGIC powder powder coatings are available for the following equipment:

1. Corona electrostatic spraying

2. Electrostatic fluidized bed

3. F luidized bed

4,Can provide suitable for frictional electrification coating Products

Coating thickness: 40-150 microns, recommended film thickness 50-80 microns

Average coverage: 10-12 square meters / kg, film thickness 60 microns (calculated at 100% usage)

Powder physical properties

Specific gravity: 1.4~1.8g/cm3 (depends on formula and color)

Particle size distribution: varies depending on the application, the standard type is an average particle size of 35-40 microns, less than 10 microns powder no more than 10%, greater than 90 microns powder no more than 0.5%.

Film properties: All tests were carried out using a 0.8 mm thick degreasing and rust-removed cold-rolled steel sheet with a film thickness of 50-80 μm.

Mechanical properties: pencil hardness GB/T 6739-1996 H-2H

Adhesion (cross-cut method) GB/T 9286-1998 Level 0

Bending test GB/T 6742-1986 ≤ 2mm

Impact test GB/T 1732-1993 ≥7mm

Corrosion resistance test: salt spray test GB/T1771-1991>500 hours No effect, and the corrosion width at the fork does not exceed 2mm

Damp heat test GB/T1740-1979>1000 hours No change

Temperature resistance 100 ° C / 48 hours (white template) gloss retention excellent color retention Color difference ≤ 0.5

Weathering performance Accelerated photoaging test QUV-No 13 (240h, 8h/60°C illumination, 4h/50°C condensation GB/T14522-1993) gloss retention ≥80%

The above coating film performance index may be slightly lowered as the gloss is lowered.

Product packaging: carton packaging, lined with two layers of PVC plastic bags, each net weight 20KG.

Storage conditions: polyester/TGIC powder coating should be stored in a dry, ventilated room at 35 °C, while avoiding direct sunlight. If stored in an air-conditioned room, the powder must be stored at room temperature or at the same temperature (temperature) as the spraying equipment. To avoid the return of moisture, the powder can be stored stably for 12 months under this condition, and the test can be re-examined in the overdue period. If the result meets the requirements, it can still be used.

Note: For low temperature curing type and powder with gloss below 40% (60 °C), the storage temperature is lower than 30 °C.

Hygiene and Safety Powder coatings All materials do not contain toxic substances, no toxic gases are generated during baking, but should avoid inhaling dust during use. Operators should wear dust masks and minimize skin contact with powder coatings. The paint attached to the skin can be washed with soap.

All products are packed with standard plastic bags and carton.

Net weight 20kg, and ensure no-leaking.

For destination of harsh climate,

we will do a good job holding shipments, avoid product deterioration.