- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Delivery Time:

-

20

-

Type:

-

seamless rolled ring

-

Technical:

-

hot forged

-

Dimension:

-

ODM

-

Heat treatment:

-

annealed

-

Surface:

-

Polishing Finish

-

Quality control:

-

chemical,mechanical and dimension

-

Mill's certificate:

-

en10204 3.1 or 3.2

Quick Details

-

Steel Grade:

-

4cr13

-

Tolerance:

-

custom, as per customer's request

-

Grade:

-

4cr13

-

Place of Origin:

-

China

-

Delivery Time:

-

20

-

Type:

-

seamless rolled ring

-

Technical:

-

hot forged

-

Dimension:

-

ODM

-

Heat treatment:

-

annealed

-

Surface:

-

Polishing Finish

-

Quality control:

-

chemical,mechanical and dimension

-

Mill's certificate:

-

en10204 3.1 or 3.2

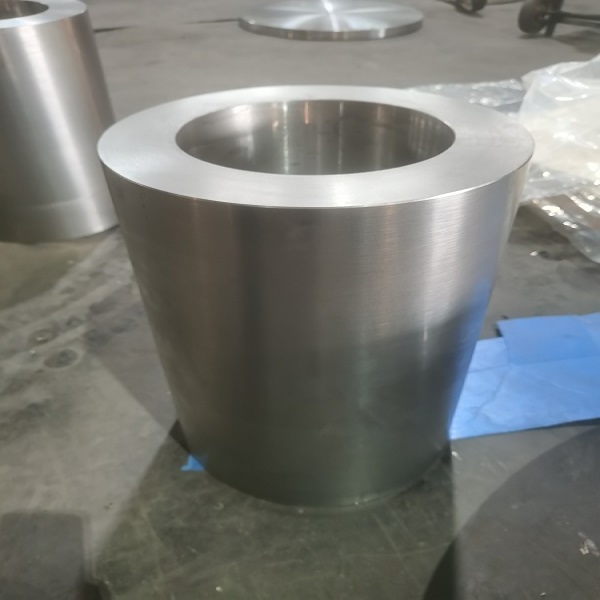

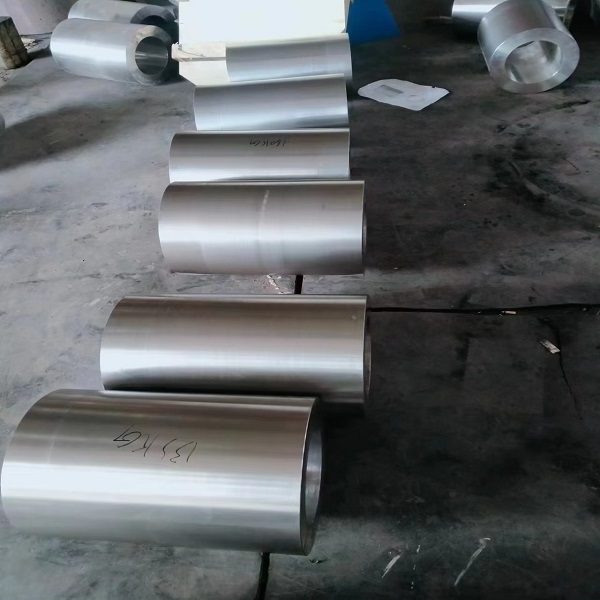

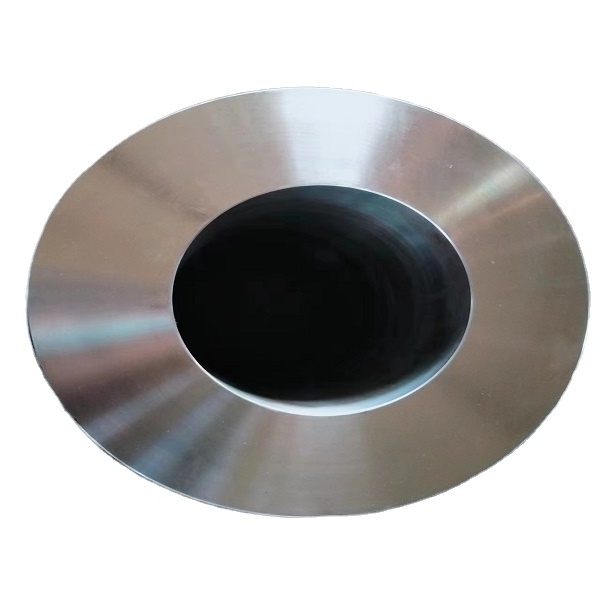

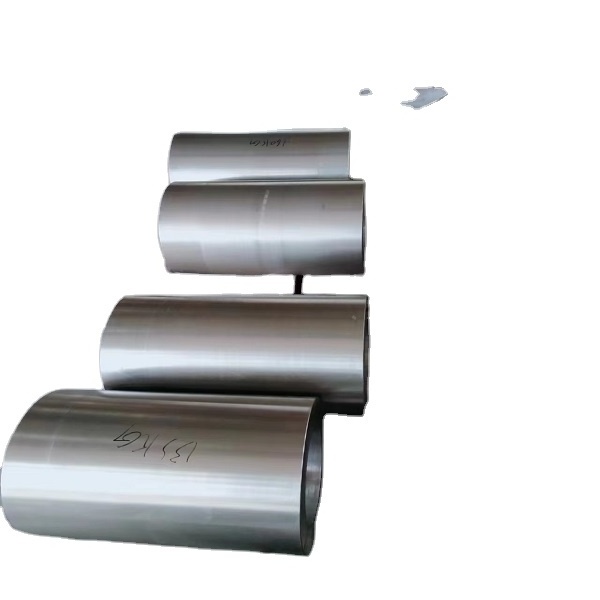

ODM 4Cr13 1.2083 aisi420 Special Stainless Steel Hot Forged Seamless Rolled Ring Forging

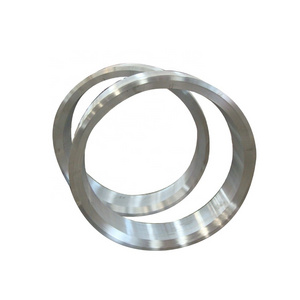

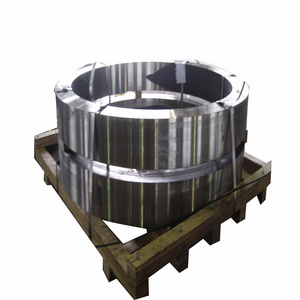

The production of seamless forged rings is often performed by a process called ring rolling on rolling mills. These mills vary in size to produce forged rings with outside diameters of just a few inches to over 300 inches and in weights from a single pound up to over 300,000 pounds.

What is Rolled Ring Forging?

The ring rolling process starts with a circular preform of metal that has been previously upset and pierced (using the open die forging process ) to form a hollow “doughnut.” This doughnut is heated above the recrystallization temperature and placed over the idler or mandrel roll. This idler roll then moves under pressure toward a drive roll that continuously rotates to reduce the wall thickness, thereby increasing the diameters (I.D. and O.D.) of the resulting ring.

Seamless rolled rings can be produced in configurations ranging from flat, washer-like parts to tall, cylindrical shapes, with heights ranging from less than an inch to more than 9 feet. Wall thickness to height ratios of rings typically range from 1:16 up to 16:1, although greater proportions can be achieved with special processing. The simplest and most commonly used shape is a rectangular cross-section ring, but shaped tooling can be used to produce seamless rolled rings in complex, custom shapes with contours on the inside and/or outside diameters.

Forge Design & Engineering Guidance

Metallurgical Review, NDE & Destructive Testing

We offer many size forgings in both standard and unique geometries to meet your needs.

Step Shafts, Eccentric Shafts & Rotor Shafts

Forged ring:4cr13 forging round mold, forging ring forged ring ,forging part.

Material:c45 c15 c60 c65 40Cr 40CrNiMo 4Cr13 20CrMnTi 16Mn 42CrMo ...etc.

Weight:50kg-3000kg

Processes: die forging close die forging open die forging.

Standards: ASTM ASME AISI API UNI SIS DIN .

According to customer demand packaging, heat treatment.

|

DIN Standard |

X46Cr13(INOX) |

20CrNiMo& 20CrMnTi and 42CrMo |

|

|

Other Grade |

AISI 420 |

AISI8620 and AISI4140 |

|

|

Material Type |

Stainless Steel |

Alloy Steel |

|

|

Hardness |

2x soft annealed max. 207HB |

annealed to 170-210 HB |

|

|

Material Allowance |

+5. mm (OD, H) radius / -5.0 mm (ID) radius |

|

|

|

Surface Finished |

Machined(rough turned with material allowance) |

|

|

|

US Test / Inspection |

SEP 1921 PG3, D, d (12/84) / EN 10204/3.1 (CA, BHN, US) |

|

|

|

Grain Size |

(ASTM E112):6-8 ASTM |

|

|

1.Select high-quality raw materials, secondary steelmaking, degassing billet;

2.Ring die material: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) or other custom materials;

3.Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output;

4.Select the combination of vacuum furnace and continuous quenching furnace to ensure long service life;

5.According to the principle and requirements of the customer to design compression ratio and strength;

6.Microscopic examination to ensure product quality;

42Crmo / 20CrMnTi alloy steel ring die processing technology:

Cutting→Forging→Normalizing→Roughing→Tempering→Finishing→Drilling (Expanding) Hole→ Carburizing→ Grinding→(Excluding Oxidation Layer) →Pressure Testing→(Phosphorus Passivation)→Coating Antirust Oil→ Check and save options ;

X46Cr13 / 4Cr13 stainless steel ring die processing technology:

Cutting→ Forging→ Roughing→ Normalizing →Finishing →Quenching and tempering→ › Finishing →Drilling hole→ Nitriding → Polishing →Pressure test→ Coating resistance →Rusty oil