- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Silencing check valve

-

Brand Name:

-

RUNTAIDA

-

Product name:

-

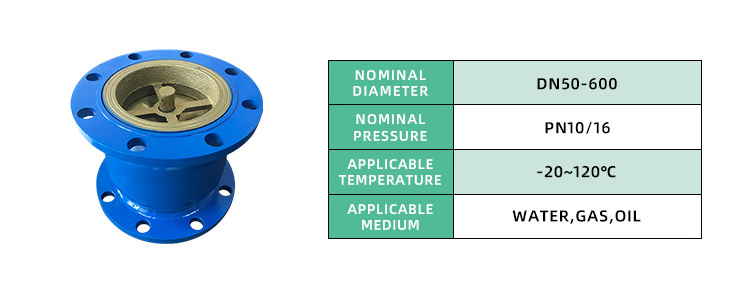

vertical lift HC41X-16 noise elimination Silent check valve

-

Nominal diameter:

-

DN50-DN600

-

Nominal pressure:

-

PN10/16

-

Applicable temperature:

-

-20℃-120℃

-

Applicable medium:

-

Water,gas,oil,etc

-

Material:

-

Carbon steel/ Ductile Iron/Stainless steel

-

Drawings:

-

Offer

-

MOQ:

-

1 Piece

-

OEM:

-

Offer

-

Brand:

-

RUNTAIDA

Quick Details

-

Port Size:

-

DN50-DN600

-

Warranty:

-

1 Year

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Silencing check valve

-

Brand Name:

-

RUNTAIDA

-

Product name:

-

vertical lift HC41X-16 noise elimination Silent check valve

-

Nominal diameter:

-

DN50-DN600

-

Nominal pressure:

-

PN10/16

-

Applicable temperature:

-

-20℃-120℃

-

Applicable medium:

-

Water,gas,oil,etc

-

Material:

-

Carbon steel/ Ductile Iron/Stainless steel

-

Drawings:

-

Offer

-

MOQ:

-

1 Piece

-

OEM:

-

Offer

-

Brand:

-

RUNTAIDA

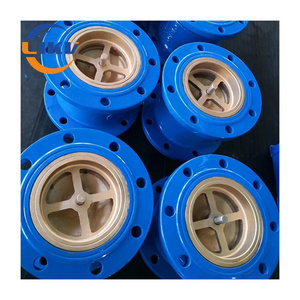

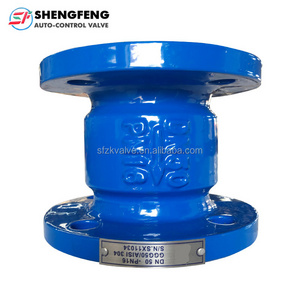

Products Description

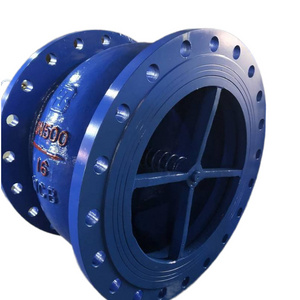

Silencing check valve refers to the valve that automatically opens and closes the valve disc depending on the flow of the medium itself, which is used to prevent the medium from flowing back. It is also called check valve, one-way valve, anechoic check valve, counter flow valve and back pressure valve.

Check valve is a kind of automatic valve, its main function is to prevent medium backflow, prevent pump and drive motor reverse, as well as container medium discharge. The check valve can also be used to supply the auxiliary system whose pressure may rise above the system pressure. Check valve can be divided into swing check valve (rotating according to the center of gravity) and lift check valve (moving along the axis).

product advantage

1.The thickness of valve body wall is up to standard.

The valve body wall thickness meets the requirement of GB 26640, the thickness is up to the standard, and the pressure strength is guaranteed.

2.Provide material inspection report.

our products can provide the material inspection report of the main parts.

After a series of strict inspection process, our products will be packaged and delivered to customers.

The picture below shows: packed and ready for delivery

The picture below shows: packed and ready for delivery

Construction and installation of silencing check valve

1. The installation position, height and direction of inlet and outlet must meet the design requirements. The direction of medium flow shall be consistent with the direction of arrow marked on the valve body, and the connection shall be firm and tight

2. The appearance inspection must be carried out before the valve is installed, and the valve name plate shall comply with the current national standard: General valve mark (GB 12220).

3. Don't make the check valve bear weight in the pipeline, large check valve should be supported independently, so that it is not affected by the pressure generated by the piping system.

Precautions for installation of silencing check valve:

1. During installation, pay attention to the direction of medium flow should be consistent with the direction of arrow marked on the valve body.

2. Lift type vertical disc check valve shall be installed on vertical pipeline.

3. Lift type horizontal disc check valve shall be installed on horizontal pipeline.

Q: Can you make the product as per client's requirement?

A: Yes, we can make it with your exact requirement

Q: What are your payment terms?

A: T/T (30% as desposit, the rest 70% will be paid before delivery), L/C at sight

Q: Where is your nearest loading port?

A: Shanghai, Qingdao or Tianjin, China.

Q: How can you guarantee the quality or any warranty?

A: If any quality problems during use, all the products can be returned or according to consumer's requests

Q: Do you accept small quantity order?

A: Of course we do.

Q: And what is your shipment and delivery time?

A: By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

A: Yes, we can make it with your exact requirement

Q: What are your payment terms?

A: T/T (30% as desposit, the rest 70% will be paid before delivery), L/C at sight

Q: Where is your nearest loading port?

A: Shanghai, Qingdao or Tianjin, China.

Q: How can you guarantee the quality or any warranty?

A: If any quality problems during use, all the products can be returned or according to consumer's requests

Q: Do you accept small quantity order?

A: Of course we do.

Q: And what is your shipment and delivery time?

A: By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

Hot Searches