- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

xx

-

Weight:

-

910 KG

-

Product name:

-

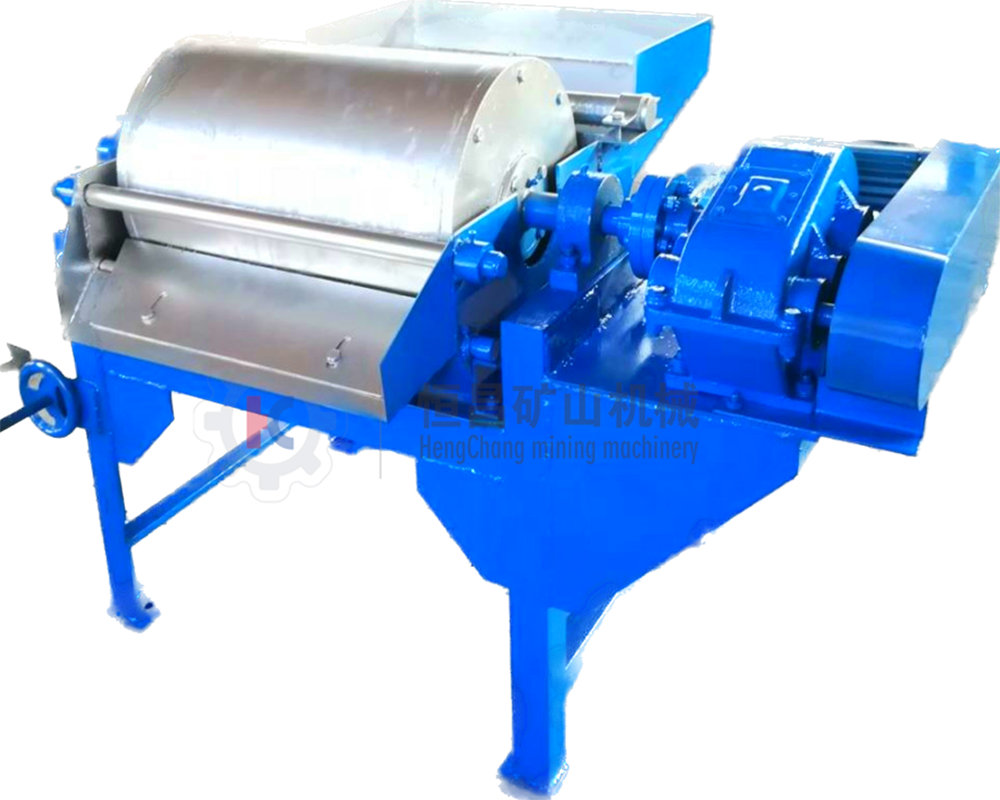

wet magnetic separator

-

Application:

-

Iron Ore

-

specification:

-

600*900

-

rotation speed of the drum:

-

40 r/min

-

Feeding size:

-

0-0.2 mm

-

capacity:

-

8-15 tph

-

power:

-

1.5 kw

-

Name:

-

magnetic separator

-

Usage:

-

Mining Separation

-

Function:

-

Washing Gold Ore

Quick Details

-

Production Capacity:

-

90%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Hengchang

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

xx

-

Weight:

-

910 KG

-

Product name:

-

wet magnetic separator

-

Application:

-

Iron Ore

-

specification:

-

600*900

-

rotation speed of the drum:

-

40 r/min

-

Feeding size:

-

0-0.2 mm

-

capacity:

-

8-15 tph

-

power:

-

1.5 kw

-

Name:

-

magnetic separator

-

Usage:

-

Mining Separation

-

Function:

-

Washing Gold Ore

High Gradient Wet Magnetic Separator for Magnetite and Coal Washing

Hengchang

magnetic seperator

can be used for many minerals grinding, such as iron ,coal,

titanium,

Pyrite

ore and so on. When you find us , you find the best mining machinery manufacturers.

High Gradient Wet Magnetic Separator for Magnetite and Coal Washing

Introduction:

Magnetic separator is suitable for materials with magnetic difference, which is widely used for resource recovery, timber industry, mining industry, ceramics industry, chemical industry, food,etc.. Magnetic separator is suitable for wet separating of materials with below 5mm sizes, such as magnetite, pyrrhotite, roasted ore, ilmenite and other materials. It is also used to remove iron from coal, non-metallic minerals, building materials,etc.. it is one of the most extensive and high versatility devices.

High Gradient Wet Magnetic Separator for Magnetite and Coal Washing

Working Principle:

When the raw materials flow into the tank body of the wet drum magnetic separator, firstly, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation. In the second step, the flushing water below flush the raw materials back for the second separation. This time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall to the ore concentrate box under gravity. Also, the flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe for tailings.

High Gradient Wet Magnetic Separator for Magnetite and Coal Washing

Application

1.Used for pre-concentration in the magnetic separation mill, remove the waste stones out of the ore

and restore grade.

2.Used for stope to recover iron ore from the tailings and increase the utilization rate of ore resources.

3.Used for the iron and steel factories. Handle the discarded steel slag and mill scales to recover the iron.

4.Used for the garbage handling. Recover the useful metals and improve the quality of environment.

and restore grade.

2.Used for stope to recover iron ore from the tailings and increase the utilization rate of ore resources.

3.Used for the iron and steel factories. Handle the discarded steel slag and mill scales to recover the iron.

4.Used for the garbage handling. Recover the useful metals and improve the quality of environment.

|

Wet Magnetic Seperator type

|

Drum Specs

|

|

Rotation speed(rpm)

|

Handling Capacity

|

|

Motor Power

|

||

|

|

Dia(mm)

|

Length(mm)

|

|

t/h

|

m3/h

|

kw

|

||

|

CTB/N/S44

|

400

|

400

|

45

|

1~2

|

3

|

1.1

|

||

|

CTB/N/S46

|

400

|

600

|

45

|

1~3

|

5

|

1.1

|

||

|

CTB/N/S63

|

600

|

300

|

40

|

3~5

|

8

|

1.1

|

||

|

CTB/N/S66

|

600

|

600

|

40

|

5~10

|

16

|

1.1

|

||

|

CTB/N/S69

|

600

|

900

|

40

|

8~15

|

24

|

1.1

|

||

|

CTB/N/S612

|

600

|

1200

|

40

|

10~20

|

32

|

2.2

|

||

|

CTB/N/S618

|

600

|

1800

|

40

|

15~30

|

48

|

2.2

|

||

|

CTB/N/S712

|

750

|

1200

|

35

|

15~30

|

48

|

3.0

|

||

|

CTB/N/S718

|

750

|

1800

|

35

|

20~45

|

72

|

3.0

|

||

|

CTB/N/S912

|

900

|

1200

|

28

|

18~30

|

45

|

4.0

|

||

|

CTB/N/S918

|

900

|

1200

|

28

|

25~55

|

90

|

4.0

|

||

|

CTB/N/S924

|

900

|

1800

|

28

|

35~70

|

110

|

4.0

|

||

|

CTB/N/S1015

|

1050

|

1500

|

21

|

30~55

|

95

|

4.0

|

||

|

CTB/N/S1018

|

1050

|

1800

|

21

|

40~75

|

120

|

5.5

|

||

|

CTB/N/S1021

|

1050

|

2100

|

21

|

45~88

|

140

|

5.5

|

||

|

CTB/N/S1024

|

1050

|

2400

|

21

|

52~100

|

160

|

5.5

|

||

|

CTB/N/S1027

|

1050

|

2700

|

21

|

60~110

|

180

|

7.5

|

||

|

CTB/N/S1030

|

1050

|

3000

|

21

|

65~125

|

200

|

7.5

|

||

|

CTB/N/S1218

|

1200

|

1800

|

19

|

47~90

|

140

|

5.5

|

||

|

CTB/N/S1224

|

1200

|

2400

|

19

|

82~120

|

192

|

7.5

|

||

|

CTB/N/S1230

|

1200

|

3000

|

19

|

80~150

|

240

|

7.5

|

||

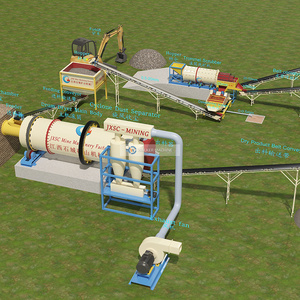

Jiangxi HenghongInternational Mining Machinery Co., Ltd. is the leading company in mining gravity separator machine designing & manufacturing in China. Up to now, we have developed four major product lines, they are mining milling machine, mining classifying separator, mining flotation machine and the mining gravity separator. We have three senior engineers and two junior engineers on equipment designing and mining process designing. At the same time, we kept good relationship with some mining research institute and university, such as Jiangxi University of Science and Technology, Ganzhou Nonferrous Metallurgy Research Institute, Hunan Research Institute of Nonferrous Metals, and etc., to improve our designing and production, and also provide technology support for the mining project. With more than 30 years in mining business, we have accumulated enough experience in gold mining plant, tungsten mining plant, wolfram mining plant, tin mining plant, cassiterite mining plant, coltan mining plant, columibte mining plant, iron ore mining plant, black/beach sand mining plant designing, manufacturing, installing, commissioning and training. We could provide

the customized complete mining solution to our customer. Our major overseas market is Africa and Southeast Asia, and our products covers 43 global countries, as more and more customers are aware of our quality products and good service, this number is growing fast.Focus areas:Mining equipent, vibrating feeder, vibrating screen, crusher, ball mill, classifying serparator, leaching tank, flotation machine, gravity seprator, shaking table, spiral chute, jig machine, centrifugal concentrator and other miningequipments.

the customized complete mining solution to our customer. Our major overseas market is Africa and Southeast Asia, and our products covers 43 global countries, as more and more customers are aware of our quality products and good service, this number is growing fast.Focus areas:Mining equipent, vibrating feeder, vibrating screen, crusher, ball mill, classifying serparator, leaching tank, flotation machine, gravity seprator, shaking table, spiral chute, jig machine, centrifugal concentrator and other miningequipments.

1. Pre-sale services:

(1) Select equipment model;

(2) Design and manufactLire products according to clients' special requirement;

(3) Train technical personnel for dients.

2.Services during the sale:

(1) Pre-check and accept products ahead of delivery;

(2) help clients to draft solving plans.

3. After-sale services:

(1) Assist dients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(1) Select equipment model;

(2) Design and manufactLire products according to clients' special requirement;

(3) Train technical personnel for dients.

2.Services during the sale:

(1) Pre-check and accept products ahead of delivery;

(2) help clients to draft solving plans.

3. After-sale services:

(1) Assist dients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

Q: Are you trading company or manufacturer ?

A: We are factory.not dealer.Direct factory sale makes price more competitive.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q : What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

A: We are factory.not dealer.Direct factory sale makes price more competitive.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q : What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Hot Searches