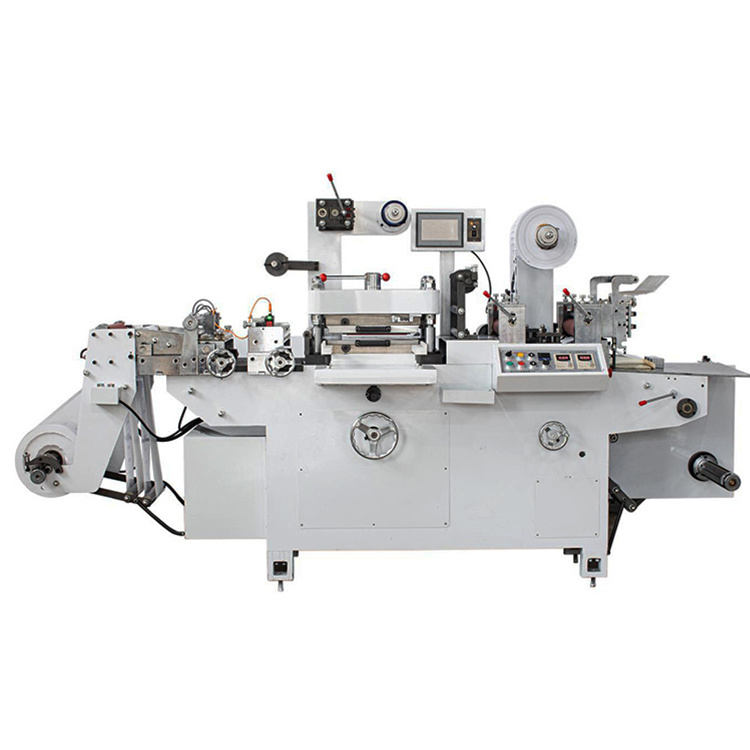

GW-FQ-320 Auto slitting machine, Slitter,label slitting machine is the auxiliary equipment of label die-cutting machinery, which is used for narrow reel material slitting. It has the function of automatic meter and number counting, automatic stopping,photocell web guiding. The machine has the characteristic of compact structure, fast speed, high efficiency, easy operation,accurate slitting and steady running etc.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Gawang Machine

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1100x900x1200mm

-

Weight:

-

400 kg

-

Max.unwinding diameter:

-

500mm

-

Max.web width:

-

320mm

-

EPC:

-

Famous in China

-

Min.slitting width:

-

320mm

-

Counting:

-

Automatic

-

Max.rewinding diameter:

-

480mm

-

Meter:

-

Automatic

-

Cutting Speed:

-

75m/min

-

Cutter:

-

Round Cutter

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

75 m/min

-

Max. workable width:

-

320mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Gawang Machine

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

1100x900x1200mm

-

Weight:

-

400 kg

-

Max.unwinding diameter:

-

500mm

-

Max.web width:

-

320mm

-

EPC:

-

Famous in China

-

Min.slitting width:

-

320mm

-

Counting:

-

Automatic

-

Max.rewinding diameter:

-

480mm

-

Meter:

-

Automatic

-

Cutting Speed:

-

75m/min

-

Cutter:

-

Round Cutter

Products Description

Description

|

Model

|

GW-FQ-320

|

GW-FQ-450

|

GW-FQ-520

|

|

Cutting speed

|

75m/minute

|

75m/minute

|

75m/minute

|

|

Max web width

|

320mm

|

450mm

|

520mm

|

|

Max unwinding diameter

|

500mm

|

500mm

|

500mm

|

|

Max rewinding diameter

|

480mm

|

480mm

|

480mm

|

|

Overall dimension

|

1.1(L)×0.9(W)×1.2 (H)m

|

1.1(L)×1.2(W)×1.3 (H)m

|

1.1×1.45×1.3(LxWxH)

|

|

Power voltage

|

220v±10%

|

220v±10%

|

220v±10%

|

|

Weight

|

About 400kg

|

About 500kg

|

About 700kg

|

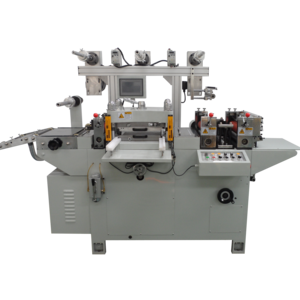

Advantage:

1. Human-machine integration: the machine adopts imported electrical appliances to be flattened and pressed up. Laminating, die cutting, feeding, waste discharging, slicing or reeling are completed by computer control at one time. It can be equipped with computer bronzing function. Both sides and longitudinal of the material are tracked and positioned by the optical eye. Fully automatic high-precision die cutting realizes the man-machine integrated function.

2. Scope of application: die-cutting of paper stickers trademarks, nylon film trademarks, and laser anti-counterfeiting trademarks The best supporting equipment for molding machine. It is also an ideal model for each trademark printing factory. Suitable for die cutting and forming in the electronics industry and adhesive tape products industry.

3. Adhesive products: various electronic, electrical appliances, special pads for mobile phones, silicone stickers, Velcro, conductive adhesive, strong double-sided adhesive.

4. Dustproof materials: cosmetic cotton, camera cotton, high-density sponge, filter cotton, dustproof net, non-woven fabric.

Main control: PLC and

man-machine interface, with

functions such as tracking

detection and tracking detection

Cutting system: use magnetic

powder clutch and magnetic

powder brake to control the

synchronization of cutter and

die cutting

Color mark tracking

Both sides and longitudinal direction

of the material are tracked and

positioned by photoelectric eyes.

More Products

Why Choose Us

Hot Searches