- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

150*150*100 mm, 200*100*60 mm, 200*200*60 mm, 230*220*115 mm, 240*115*90 mm, 300*150*100 mm, 400*100*200 mm, 400*120*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ly

-

Voltage:

-

none

-

Dimension(L*W*H):

-

80*120*160cm

-

Weight (KG):

-

160 kg

-

Name:

-

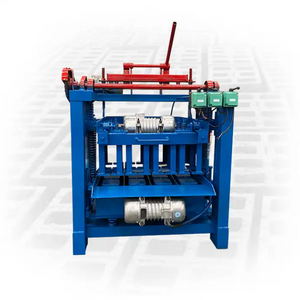

blocks making machine

-

Pressure:

-

Manual

-

Raw material:

-

Clay/Mud/Soil/Earth

-

Weight:

-

160

-

Vibration frequency:

-

50 hz

-

Molding cycle:

-

10s

-

Total power:

-

1100w

-

Maximum pressure:

-

20 KN

-

Working air pressure:

-

20 Mpa

-

Processing method:

-

Vibratory pressing

Quick Details

-

Type:

-

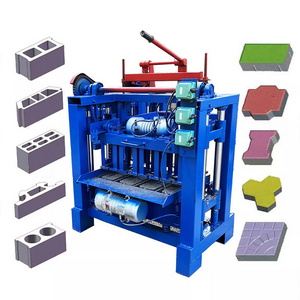

Hollow Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Other

-

Production Capacity (Pieces/8 hours):

-

2500 pcs/8hours

-

Brick size:

-

150*150*100 mm, 200*100*60 mm, 200*200*60 mm, 230*220*115 mm, 240*115*90 mm, 300*150*100 mm, 400*100*200 mm, 400*120*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ly

-

Voltage:

-

none

-

Dimension(L*W*H):

-

80*120*160cm

-

Weight (KG):

-

160 kg

-

Name:

-

blocks making machine

-

Pressure:

-

Manual

-

Raw material:

-

Clay/Mud/Soil/Earth

-

Weight:

-

160

-

Vibration frequency:

-

50 hz

-

Molding cycle:

-

10s

-

Total power:

-

1100w

-

Maximum pressure:

-

20 KN

-

Working air pressure:

-

20 Mpa

-

Processing method:

-

Vibratory pressing

Video Description

Product Description

|

Condition

|

New

|

|

Brick Raw Material

|

Other

|

|

Processing

|

Brick Molding Machine

|

|

Dimension(L*W*H)

|

80*120*160cm

|

|

Warranty

|

1 Year

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Pressure vessel

|

|

Weight (KG)

|

160kg

|

|

Name

|

blocks making machine

|

|

Pressure

|

Manual

|

|

Molding cycle

|

10s

|

|

Weight

|

160

|

|

Vibration frequency

|

50 hz

|

|

Total power

|

1100w

|

|

Maximum pressure

|

20 KN

|

|

Working air pressure

|

20 Mpa

|

|

Processing method

|

Vibratory pressing

|

Small no-burn brick machine is mainly used for pressing fly ash, river sand, sea sand, mountain sand, mineral powder, slag, stone powder, cinder, coal gangue, tailing slag, chemical slag, etc. as the main raw material for the production of no-burn bricks, porous bricks, standard bricks and hollow bricks.

The cement bricks or hollow bricks produced by the no-burn brick machine do not need to be sintered and can be shipped out of the factory through a short period of drying. It also realizes the reuse of resources, such as slag, slag and construction waste, which are all considered as garbage, can be converted into no-burn bricks by the brick making machine equipment, thus realizing the recycling of resources. The quality of cement bricks is not only not inferior to the original red bricks, but also far more than the strength of red bricks.

Product Display

Hot Searches