We focus on product quality and brand building, and have won the trust and praise of customers through

strict quality control and professional brand marketing.

strict quality control and professional brand marketing.

|

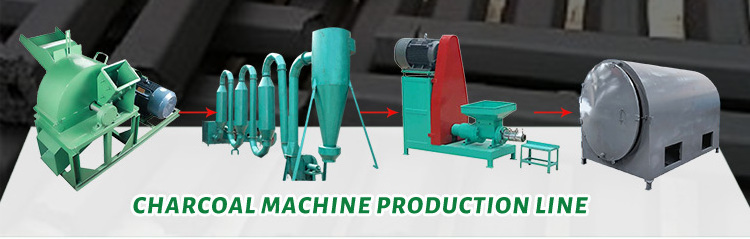

power

|

output

|

weight

|

|

18.5kw

|

180-240KG/H

|

650KG

|

|

22kw-Ⅰ

|

260-300KG/H

|

800KG

|

|

22kw-Ⅱ

|

320-350KG/H

|

1000KG

|

|

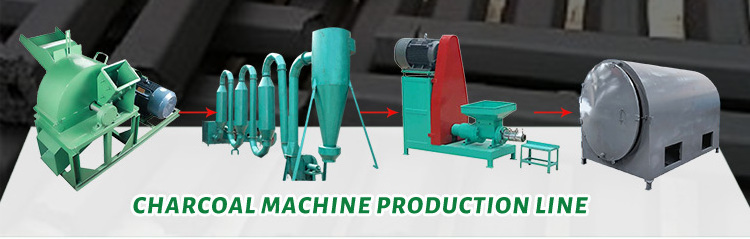

power

|

output

|

weight

|

|

18.5kw

|

180-240KG/H

|

650KG

|

|

22kw-Ⅰ

|

260-300KG/H

|

800KG

|

|

22kw-Ⅱ

|

320-350KG/H

|

1000KG

|

|

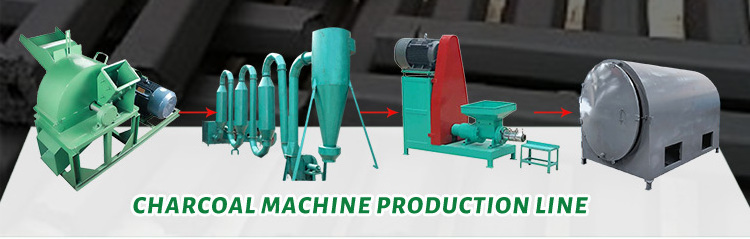

power

|

output

|

weight

|

|

18.5kw

|

180-240KG/H

|

650KG

|

|

22kw-Ⅰ

|

260-300KG/H

|

800KG

|

|

22kw-Ⅱ

|

320-350KG/H

|

1000KG

|

|

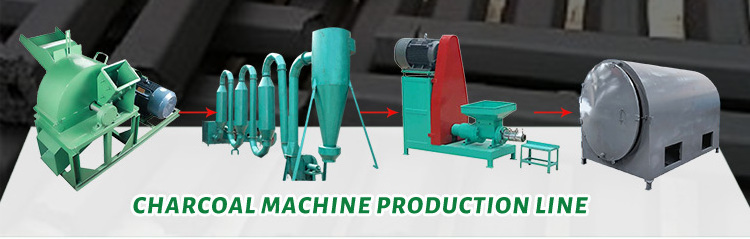

power

|

output

|

weight

|

|

18.5kw

|

180-240KG/H

|

650KG

|

|

22kw-Ⅰ

|

260-300KG/H

|

800KG

|

|

22kw-Ⅱ

|

320-350KG/H

|

1000KG

|