Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

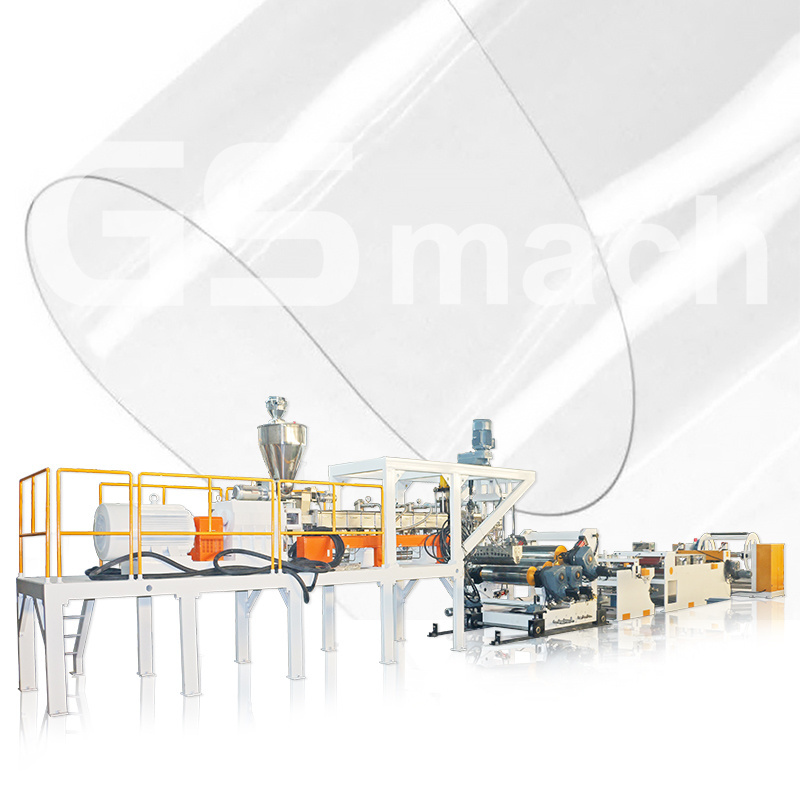

Brand Name:

-

GS-mach

-

Voltage:

-

380V/220V 3P

-

Dimension(L*W*H):

-

18M*2.6M*2.8M

-

Power (kW):

-

250

-

Weight:

-

20000 KG

-

Model:

-

GS1400mm

-

Feature:

-

plastic sheet manufacturing machine

-

Adaption Material:

-

PLA & PET & PP

-

Sheet Thickness:

-

0.4mm-1.6mm+-2%

-

Control:

-

PLC+Touch Screen

-

Installation Capacity:

-

232kw

-

Name:

-

pp sheet making machine

-

Description:

-

pet sheet extrusion line

-

After-sales Service Provided:

-

Field Installation maintenance and repair service

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

44:1

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS-mach

-

Voltage:

-

380V/220V 3P

-

Dimension(L*W*H):

-

18M*2.6M*2.8M

-

Power (kW):

-

250

-

Weight:

-

20000 KG

-

Model:

-

GS1400mm

-

Feature:

-

plastic sheet manufacturing machine

-

Adaption Material:

-

PLA & PET & PP

-

Sheet Thickness:

-

0.4mm-1.6mm+-2%

-

Control:

-

PLC+Touch Screen

-

Installation Capacity:

-

232kw

-

Name:

-

pp sheet making machine

-

Description:

-

pet sheet extrusion line

-

After-sales Service Provided:

-

Field Installation maintenance and repair service

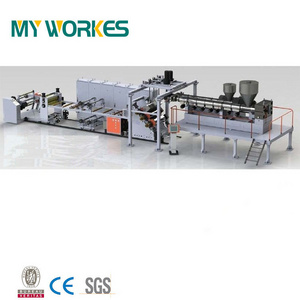

Machine Introduction

PP PS PE SHETT EXTRUDER MACHINE (SINGLE SCREW DESIGN)

PP PS PE SHETT EXTRUDER MACHINE

This production line is suitable for PET sheet can achieve famous crystallization, no drying characteristics, at the same time we use PET special alloy steel thin wall roller set, so that the cooling efficiency is greatly improved, thereby increasing the output, improve the toughness of products, transparency. In addition, our independent programming operating system ensures that the equipment is humanized and easy to operate

For the Raw materials use we can use the clean pet plastic flakes and pet recycled granules as the raw materials for the pet sheet making , also our

Our new PET bottle flakes recycling technology enables the process to get rid of pre-drying step.The combination of twin screw extruder and high efficient vacuum system streamlines the whole process, yet keeps the final pellets in good quality. PET recycled pellet making machine is a good choice for the raw materials production of the sheet machine

Factory Machine photos

Advantages

1. Double screw double exhaust structure, can fully remove the gas and volatiles in the material from the plasticized material;

2. Maintain good material mixing effect and plasticizing quality, greatly improve sheet quality and reduce sheet processing defects;

3. No crystallization and no drying, greatly reducing the drying cost;

4. Modular design, compact structure, easy operation, simple maintenance, reduce labor costs;

5. Can achieve online crushing edge material, automatic coil change, winding, improve product quality;

6. Use electronic software system, parameter setting, data operation, alarm and other automatic functions to reduce labor costs.

Machine Analysis

Machine Configuration

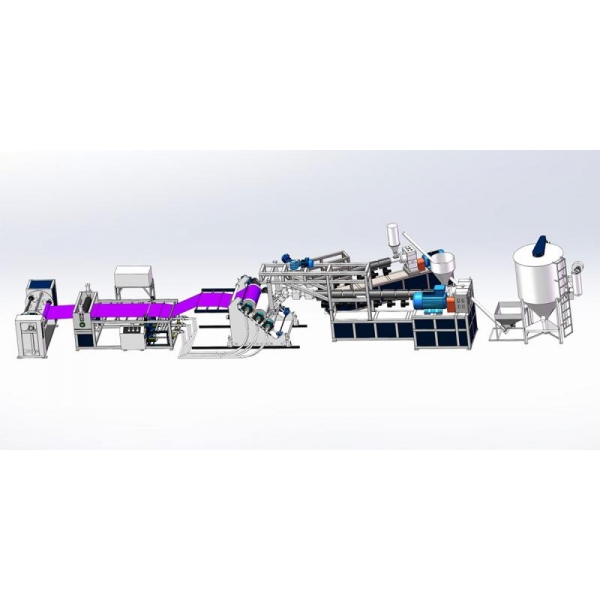

Twin screw metering feeder----

Twin screw extruder----

Hydraulic screen changer----

Melt pump----

T-die----

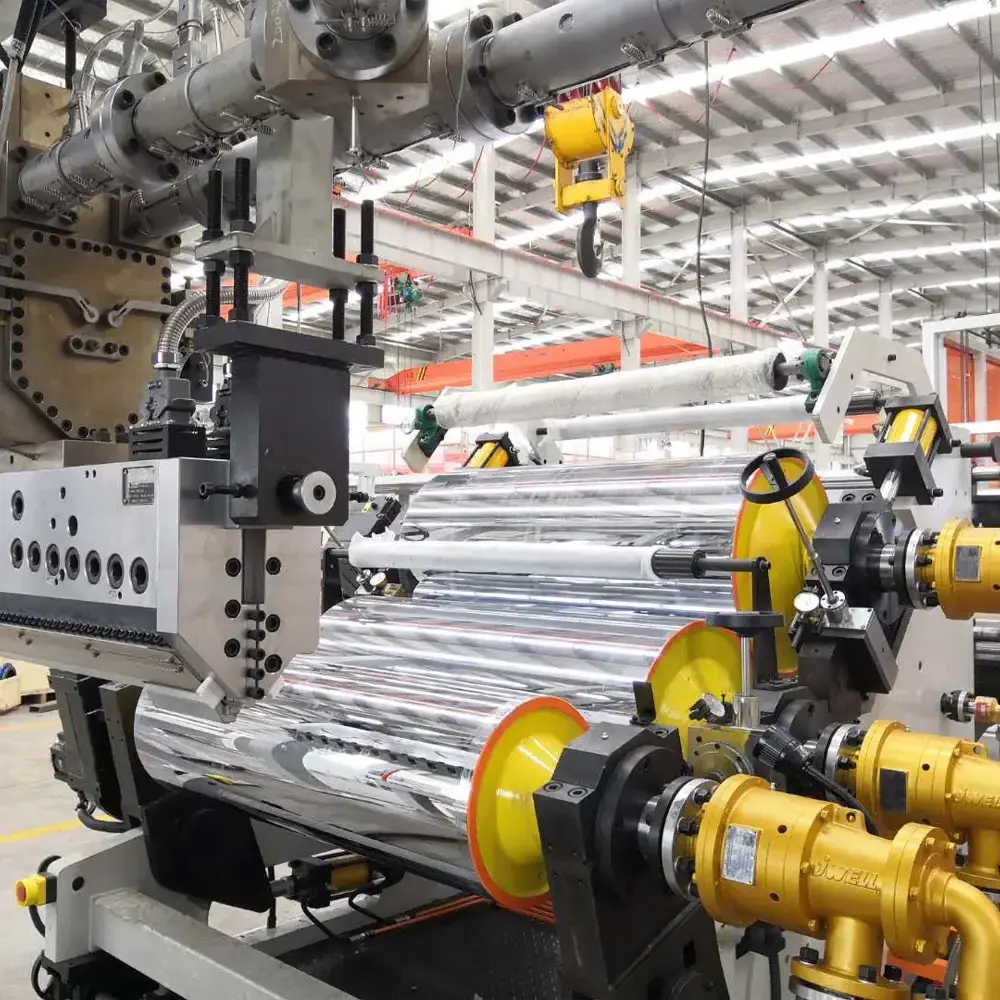

Three roller calender machine----

Tractor & edge cutter----

Silicone oil coating device----Oven----

Double station winder machine

Twin screw extruder

The parallel twin-screw extruder has excellent mixing performance, good self-cleaning performance, flexible modular combination and other characteristics, which can be adapted to different types of processing of a variety of material systems.

T - Die &

Mirror three rollers

The sheet thickness control adopts screw adjustment and press wheel bidirectional adjustment control, which is more accurate. Three roller mirror roller, horizontal, vertical or 45 degree tilt, can be lifted and lowered. More intelligent.

Automatic pulling machine, winding machine, cutting machine

Automatic traction and winding, improve production capacity while reducing product consumables, save labor.

Fished Product Gallery

.

Application area

1. Medical Packing .2. PET Advertising Light Box 3.PET Soundproof Screen

Technical Parameters

|

Model

|

Raw Materials

|

Width(mm)

|

Thickness(mm)

|

Capacity (kg/h)

|

|

GS-65

|

PET/APET/PLA/PP/PE/PS/PC,etc

|

500-800

|

0.15-2.5

|

200-450

|

|

GS-75

|

PET/APET/PLA/PP/PE/PS/PC,etc

|

800-1000

|

0.15-2.5

|

400-750

|

|

GS-95

|

PET/APET/PLA/PP/PE/PS/PC,etc

|

1000-1200

|

0.15-2.5

|

800-1000

|

Why Choose Us

Paul

whatsapp: +86 18112933051

Email:

extruder3@njgsmach.com

website: www.njgsmach.com

Hot Searches