- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

380V

-

Power:

-

0.22kw

-

Weight (KG):

-

4200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Coconut Shell coal making Machine

-

Raw material:

-

Biomass Wastes

-

Capacity:

-

1.5-2t/day

-

Carbonization time:

-

6-8 Hours

-

Cooling Time:

-

5-8 Hours

-

Fuel:

-

Firewood,Gas

-

Advantage:

-

Energy Saving

-

Color:

-

Customer's Request

-

Installation:

-

Engineer Guide

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Effective Volume:

-

2.75*3CBM

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

380V

-

Power:

-

0.22kw

-

Weight (KG):

-

4200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Coconut Shell coal making Machine

-

Raw material:

-

Biomass Wastes

-

Capacity:

-

1.5-2t/day

-

Carbonization time:

-

6-8 Hours

-

Cooling Time:

-

5-8 Hours

-

Fuel:

-

Firewood,Gas

-

Advantage:

-

Energy Saving

-

Color:

-

Customer's Request

-

Installation:

-

Engineer Guide

Economical Coconut Shell Charcoal Coal making Machine Coconut Shell Activated Carbon machine

| Introduction |

This is our Wood Airflow Continuous Coconut Shell Charcoal Carbonization Stove Furnace Retort Kiln Machine. It can make the raw materials such as manmade wood briquettes,wood log,wood branch,bamboo,coconut shell etc. into charcoal directly.

How to produce charcoal? It divides into three processes:

1. Heat

After sealing work, use wooden wastes or gas to heat furnace. Primarily, 10 minutes big fire to burn, when the temperature reaches 90 degrees centigrade, turn to use slow fire to heat. It takes 80-120minutes for this process to reduce water vapor from your materials.

2. Pyrolyse

Keep heating, when the temperature reaches 180-235 degrees centigrade for 3-5hours, it will produce gas from this process. Reuse this gas as fuel to heat. The whole process is about 8hours. When the temperature reach highest and it reduces, the dry distillation process will finished.

3. Cooling

Hang the Inner pot outside, and seal the pipes of cover. Let it cool naturally. Cooling time is longer, the quality of charcoal is good. When the temperature lowers than 50 degree, you can take charcoal out. Otherwise, the charcoal will burn again when met oxygen of air.

|

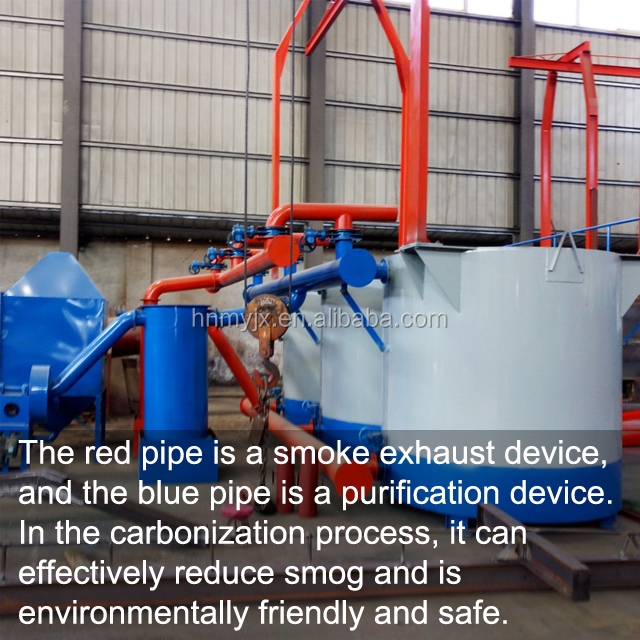

Structure |

This Wood Airflow Continuous Coconut Shell Charcoal Carbonization Stove Furnace Retort Kiln Machine includs one outer stove, three inner stoves,caps,hoisting equipment,purification system.

Outer stove

includes heating room (for heating the stove), furnace body and heat-keeping layer (it is made of the heat insulating material, used for keep the heating)

Inner stove

Consist of the stove tank body and the sealed top cap.Both of them are made of the heat resistance thermal steel,and the three carbonization baskets can be stack together,

easy for loading and transporting ,and it will save a lot of space and transport charge.

Purification tank

When during the process of carbonizing, there will be some smoke( can be burning) the smoke can return to the furnace through tube for purifying, after purification , the combustible smoking can be flow into the heating room of the outer stove for heating the stove again;

This system is consisting of purification tank and the exhaust heated cycle pipe. And Smoking purification tank are used for purify the smoking (can not Burning)and filter the wood tar. The smoking through the purification tank will Become water vapor, and it will not pollute the air.

Hoisting equipment

it includes the steel hoisting frame and the E-hoist .And it is easy for loading and unloading the stove, and can reduce labor intensity,

| Working principle |

When one inner stove have been finished carbonization, we will use the hoisting tools to hoist the inner stove out of the outer stove, then put down the inner stove on earth for natural cooling, at the same time, we can put another inner stove into the outer stove for the second carbonization,which will save a lot of time, so the productivity increase a lot, it is the ideal choice for mass production of charcoal.

How to produce charcoal? It divides into three processes:

1. Heat

After sealing work, use wooden wastes or gas to heat furnace. Primarily, 10 minutes big fire to burn, when the temperature reaches 90 degrees centigrade, turn to use slow fire to heat. It takes 80-120minutes for this process to reduce water vapor from your materials.

2. Pyrolyse

Keep heating, when the temperature reaches 180-235 degrees centigrade for 3-5hours, it will produce gas from this process. Reuse this gas as fuel to heat. The whole process is about 8hours. When the temperature reach highest and it reduces, the dry distillation process will finished.

3. Cooling

Hang the Inner pot outside, and seal the pipes of cover. Let it cool naturally. Cooling time is longer, the quality of charcoal is good. When the temperature lowers than 50 degree, you can take charcoal out. Otherwise, the charcoal will burn again when met oxygen of air.

The difference of new design wood charcoal carbonization stove comparing with other suppliers:

♦ Thickness of outer stove is: wall --- 6mm, bottom --- 12mm, other supplier uses 3mm and 8mm.

♦ Thickness of Inner pot is: wall --- 8mm, bottom --- 12mm, other supplier uses 4mm and 6mm.

♦ The brick we used for building outer stove is good quality, high temperature resistance, white refractory bricks. Other supply uses common bricks.

| Raw materials and final charcoal |

| Technology parameter |

|

Model |

Capacity |

Inner Volume |

Temperature |

Machine Include |

|

QHL-1 |

1.5-2t/24h |

2.75*3 |

400-600degree |

1outer stove, 3inner stoves with3 caps , one 3ton lifting device, 1smoking tank |

|

QHL-2 |

3-4t/24h |

2.75*6 |

400-600 degree |

2 outer stove, 6 inner stoves with 6 caps, one 5-ton hoisting equipment withe-motor, 1smoking tank |

|

QHL-3 |

4.5-6t/24h |

2.75*9 |

400-600 degree |

3 outer stove, 9 inner stoves with 9caps, one 5-ton hoisting equipment with e-motor, 1smoking tank |

|

QHL-4 |

6-8t/24h |

2.75*12 |

400-600 degree |

4 outer stove, 12 inner stoves with 12caps, one 5-ton hoisting equipment with e-motor, 1 smoking tank |

After high-temperature pyrolysis, the main final product we get is artificial carbon with a fixed high carbon content (about 80- 90%).

Compared with ordinary coal, its carbon content is about twice that. In addition, tar, wood vinegar,

and combustible gas can also be obtained during the carbonization process.

wood tar

wood vinegar

combustible gas

QHL-1

QHL-2

QHL-3

QHL-4

|

Learn more about the machine and the latest price , p lease click @ CONTACT US

|

Clients site

in our plant we aslo have the Continuous carbonziation stove :

| Packing and Shipping |

If you order one QHL-1 or one QHL-2 carbonization stove, a 20 feet container is needed.

If you order one QHL-3 or one QHL-4 carbonization stove, a 40 feet container is needed.