- Product Details

- {{item.text}}

Quick Details

-

Knitting Method:

-

Three system

-

Computerized:

-

Yes

-

Gauge:

-

1.5 GG, 2 GG, 16 GG, 9 GG, 5 GG, 10GG, 18GG, 16GG, 8GG, 3-5-7 multi-gauge

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

OPEK

-

Power:

-

1.5 W

-

Weight:

-

1280 KG

-

Dimension(L*W*H):

-

2790*2010*940mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

3 system computerized flat knitting machine

-

Knitting system:

-

Single carriage with three system system

-

Multi-gauge:

-

3-5-7 multi-gauge , 8-10-12 multi-gauge

-

Application:

-

Sweater knitting , fabric knitting , hat and scarf knitting

-

Keywords:

-

3 system computerized flat knitting machine

-

Knittind width:

-

52 inch

-

Function, knitting pattern:

-

Fully Jacquard

-

System:

-

3 System

Quick Details

-

Type:

-

jacquard

-

Production Capacity:

-

1.2m/S

-

Knitting Style:

-

Warp

-

Knitting Method:

-

Three system

-

Computerized:

-

Yes

-

Gauge:

-

1.5 GG, 2 GG, 16 GG, 9 GG, 5 GG, 10GG, 18GG, 16GG, 8GG, 3-5-7 multi-gauge

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

OPEK

-

Power:

-

1.5 W

-

Weight:

-

1280 KG

-

Dimension(L*W*H):

-

2790*2010*940mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

3 system computerized flat knitting machine

-

Knitting system:

-

Single carriage with three system system

-

Multi-gauge:

-

3-5-7 multi-gauge , 8-10-12 multi-gauge

-

Application:

-

Sweater knitting , fabric knitting , hat and scarf knitting

-

Keywords:

-

3 system computerized flat knitting machine

-

Knittind width:

-

52 inch

-

Function, knitting pattern:

-

Fully Jacquard

-

System:

-

3 System

Product descript

double system computerized flat knitting machine

double and three system flat knitting machine

1:High speed &high output

2:CE and ISO 9001:2008 certificate.

3:Easy operation,knitting system:Single carrier with three system

4.Max speed:1.2m/s.

Main Characteristic

Single Carriage with three system , this S-Series computerized flat knitting machine are used digital technology to achieve the patterns of knit ,transfer , tuck , pointel , intarsia , jacquard ,apparent shape, hidden shape , and other regular or irregular patterns knitting functions , can knit basic single or double jersey plain fabric , irregular multi-color jacquard , intarsia , cable and pointel structure patterns , which suitable to knit by yarns of pure silk ,mixed silk , synthetic , wool ,acrylic ,mixed fiber material etc. knitted for shaping fabric and accessories of collar , cardigan ,rib, cuff, scarf ,pocket and trousers etc

.

Mainly specification

|

Gauge :

|

2.5gg,3gg, 3-5-7 multi-guague ,5gg ,7gg ,8gg, 9gg, 10gg, 12gg,

8-10-12 multi-gauge ,14gg,16gg ,18gg

|

|

|

||

|

Knitting bed width :

|

52 /56 /60/72/80 inch

|

|

|

||

|

knitting function:

|

Knit ,miss,tuck,transfer, pointel, intarsia,jacquard,hide,or apparent shaping and other regular or irregular patterns.

|

|

|

||

|

Knitting speed:

|

Controlled by servo motor, 24 sections speed optional, max 1.2M/S.varies according to gauge and knitting condition

|

|

|

||

|

Knitting system:

|

Single carriage with three system

|

|

|

||

|

Needle bed:

|

Replaceable segment needle bed ,flat needle bed

|

|

|

||

|

Take down roller:

|

Programmed instruction,controlled by marching motor, changeable 24 levels and selectable scope: 0-99.

|

|

|

||

|

Transfer:

|

Combined cam box single or double system can work independently and one system can transfer the stitch While the other system keeps knitting.

|

|

|

||

|

Racking:

|

Controlled by servo motor racking within 2 inches and with fine adjusting function.

|

|

|

||

|

Protection:

|

The machine will automatically alarm if yarn-breaking knots floating yarn rewind end of knitting, fail of racking needle breakage error programming occur.

|

|

|

||

|

Stitch system:

|

Controlled by stepping motor, 24 section stitch selectable, adjustable scope supported by subdivision technology: 0-650, the stitch of the knitwear can be accurately controlled.

|

|

|

||

|

Encoder:

|

Advanced encoder adopted.

|

|

|

||

|

Yam carrier:

|

2×8 Yarn carriers on each side of 4 guide rails, shiftable on any needle position(special instarsia carriers available).

|

|

|

||

|

Sinker system

|

Controlled by stepping motor, adjustable to different knitwear, have various results of shaping and patterns.

|

|

|

||

|

Power:

|

Singe-phase 220V, adopts advanced CMOS technology, having memorizing function at power shock stop.

|

|

|

||

|

Controller:

|

1. Screen:Adopt LCD industrial screen and figure interface,input device:USB. Internal storage 32M.The latest system 1G. A great amount of design files can be stored at the same time and they can be fetched out for using at any time as per production requirements.

|

|

|

||

|

|

2. Monitoring menu,each kind of operating parameter can be shown, and they can be adjusted at any time when the machine is running is visual and easy to understand and upgrade.

|

|

|

||

|

|

3. Free design is visual and easy to understand and upgrade

|

|

|

||

|

|

4.Multi language version :there are Chinese .English and Arabic etc. languages version ,the other language version set up shall according to customers requirement .

|

|

|

||

|

Volume and weight

|

Length×width×height: 2790×1100×1500mm Net weight :1280kg

|

|

|

||

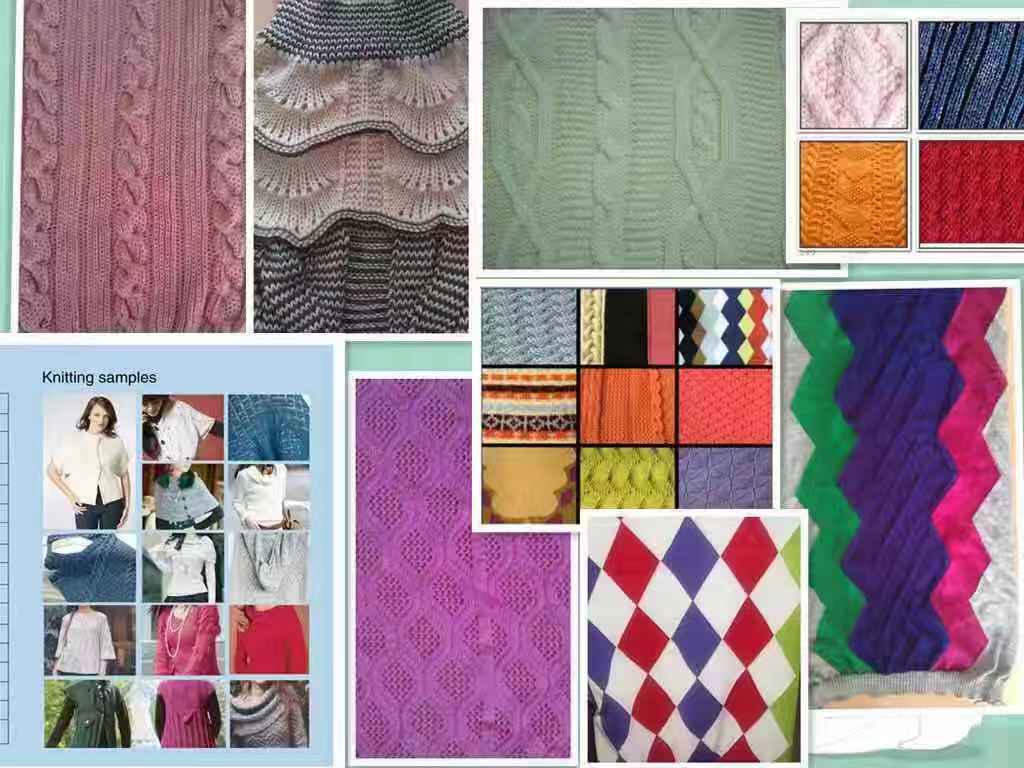

Knitting samples

Our Workshop

Packing & Delivery

Hot Searches